-

Dec.28

2022

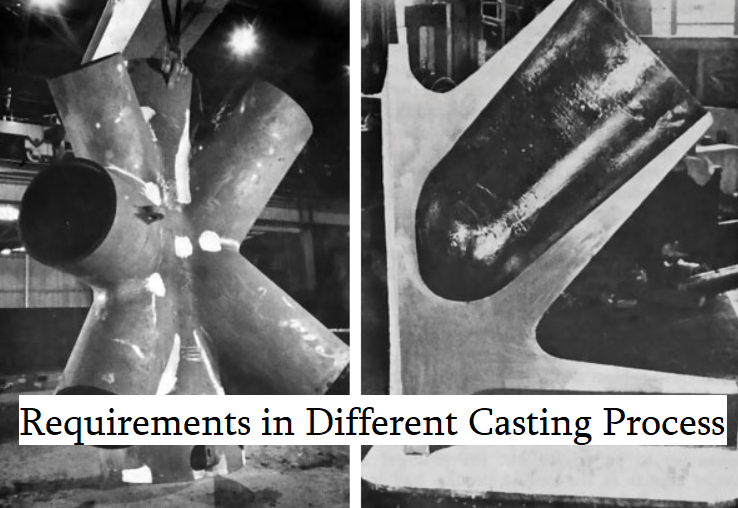

10 Effective Tips & Guidelines to Avoid or Reduce Casting DefectsIn the production of casting parts, the manufacturer will encounter casting defects such as shrinkage cavity, bubble, et...View More >> -

Dec.28

2022

Casting Structure & Design Requirements in Different Casting ProcessesFor diffrent casting methods, the requirement on casting structure and design will be different as well. C...View More >> -

Dec.28

2022

Machine Tool Casting: Selection of Material and Casting MethodMachine tool casting is a type of large-sized casting, what materials are often used to make machine castings and which ...View More >> -

Dec.25

2022

How to Prevent Corrosion on Aluminum Parts – Rust Prevention of Aluminum CastingsAfter being placed for a while, the surface of aluminum castings will appear signs of corrosion. Why does aluminum casti...View More >> -

Dec.25

2022

How to Inspect and Control the Quality of Aluminum CastingsAluminum die castings are widely used in autmotive, medical and lots of other industries, How to control and ensure the ...View More >> -

Dec.22

2022

Similarities and Differences Between Low-Pressure Casting and Gravity CastingCasting can be divided into gravity casting and pressure (die) casting according to the pouring form of liquid metal. Th...View More >> -

Dec.22

2022

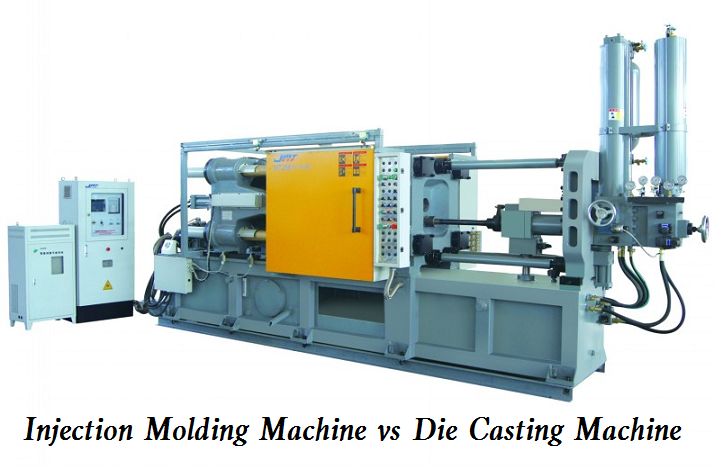

Differences Between Injection Molding Machine and Die Casting MachineInjection molding and die casting are similar processes, when it comes to equipment, what are the differences between an...View More >> -

Dec.21

2022

What Is The Prospect Of EPC? Should We Go To EPC Production Line?Although China is not the inventor of EPC technology, it is the country with the largest EPC production and one of the c...View More >> -

Dec.21

2022

Investment Casting: How It Evolved Over The YearsThere was a surge in the quantity of castings made in West Africa beginning in the 11th century. The process of investme...View More >> -

Dec.21

2022

Deburring Method of Cast Iron Machine PartsBurr is a term that describes the byproducts of any kind of processing, including but not limited to casting, forging, s...View More >> -

Dec.21

2022

What Equipment Should You Use To Polish Gray Cast Iron Components?With the continuous development of the machinery manufacturing industry, the requirements for the quality of gray cast i...View More >> -

Dec.15

2022

Differences Between OEM And ODM: OEM Vs ODMDifferences Between OEM And ODM: OEM Vs ODMView More >>