Sand casting is the most widely used method among casting technologies. The castings produced by sand casting in the world account for the majority of the total output. Today let’s get into the essential steps in the sand casting process, as we as its pros and cons.

Sand Casting Advantages and Limitations

Sand casting is the most popular and simplest type of casting that has been used for centuries Sand casting is used to make large parts, such as gray iron, ductile iron, stainless steel, and other types of steel.

Advantages:

– Clay is rich in resources and cheap. Most of the used clay-wet sand can be recycled after proper sand treatment.

– Short casting cycle and high work efficiency.

– The mixed molding sand can be used for a long time.

– Wide adaptability. Small pieces, large pieces, simple pieces, complex pieces, single pieces, and large batches can be used.

Limitations:

– Each sand mold can only be poured once, the mold will be damaged after the casting is obtained and must be reshaped, so the production efficiency of sand casting is low.

– The rigidity of the mold is not high, and the dimensional accuracy of the casting is poor.

– The casting is easy to produce sand washing, sand inclusion, air hole, and other defects.

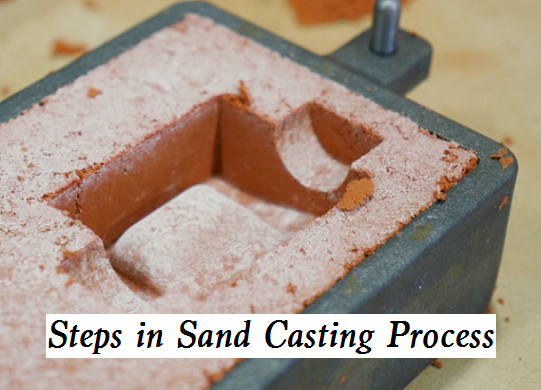

Steps in Sand Casting Process

The basic process of traditional sand mold casting process includes the following steps: sand mixing, mold making, core making, molding, pouring, sand dropping, grinding, inspection, etc

1) In the sand mixing stage, the molding sand and core sand are prepared for molding. Generally, the sand mixer is used to put the old drawing and a proper amount of clay into it for mixing.

2) In the mold-making stage, the mold and core box are made according to the part drawings. Generally, a single piece can be made of wood mold, plastic mold, or metal mold (commonly known as iron mold or steel mold) and can be made by mass production, and a large number of castings can be made of molded plates. Now the mold is basically made by a carving machine, so the production cycle is greatly shortened. It generally takes 2~10 days to make the mold.

3) Core making stage including forming the mold cavity of the casting with molding sand, core making (forming the internal shape of the casting), and mold matching (putting the clay core into the mold cavity and closing the upper and lower sandboxes). This is the key step in sand casting.

4) Melting stage: prepare the chemical composition according to the required metal composition, select the appropriate melting furnace to melt alloy materials, and form qualified liquid metal, including qualified composition and qualified temperature. A cupola or electric furnace is generally used for smelting, due to environmental requirements, the cupola is now basically banned and the electric furnace is basically used.

5) Pouring stage: molten iron in the electric furnace is injected into the mold with a ladle. Pay attention to the pouring speed when pouring molten iron to fill the entire mold cavity. In addition, pouring molten iron is dangerous, pay more attention to that.

6) Cleaning stage: after pouring and solidification of molten metal, take a hammer to remove the gate and shake off the sand of the casting, and then use a sandblasting machine to sandblast so that the casting surface will look very clean! The casting blanks with less strict requirements can be delivered after inspection.

7) Casting processing. For some castings with special requirements or some castings that cannot meet the requirements, simple processing may be required. Generally, a grinding wheel or grinder is used for processing and polishing to remove burrs and make the casting more smooth.

8) Inspection of castings, castings are generally inspected during the cleaning or processing stage, and unqualified ones are generally found. However, some castings have individual requirements and need to be checked again. For example, some castings need a central hole that can insert a 5cm shaft, so you need to put a 5cm shaft through it for a try.