-

Nov.12

2025

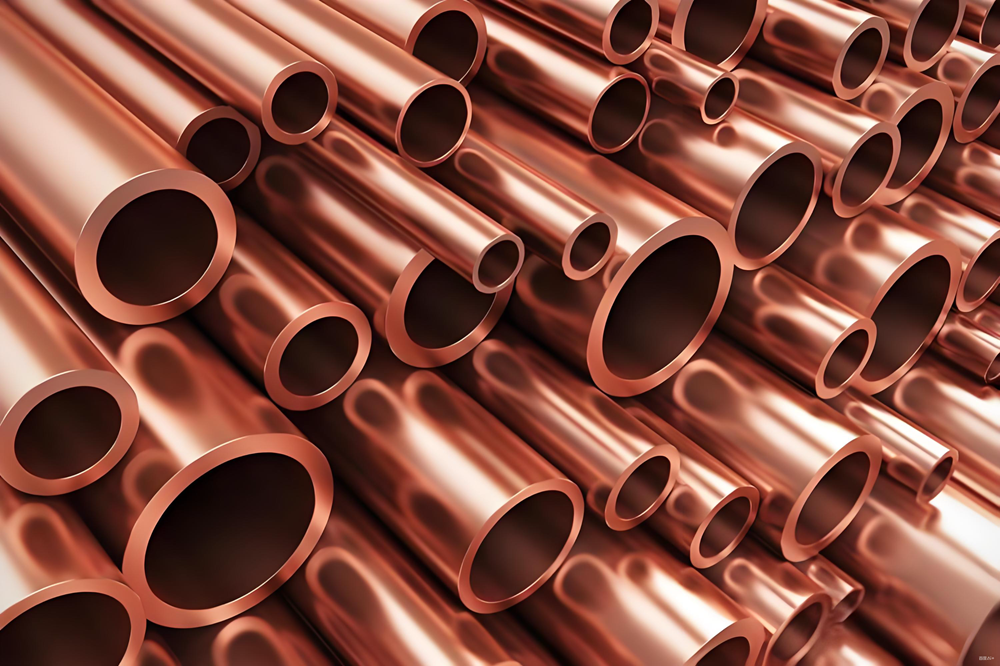

Copper Pipe/Tube Size Chart (MM & Inches) | OD, ID, Thickness & TypesCopper pipe is a mainstay in modern plumbing, HVAC, refrigeration, house and industrial applications due to its reliabil...View More >> -

Nov.11

2025

A356-T6 vs 6063-T6 Aluminum – Equivalent, Properties, Composition & DifferencesAluminium alloys are a cornerstone of modern manufacturing, offering a unique combination of lightweight performance, co...View More >> -

Nov.07

2025

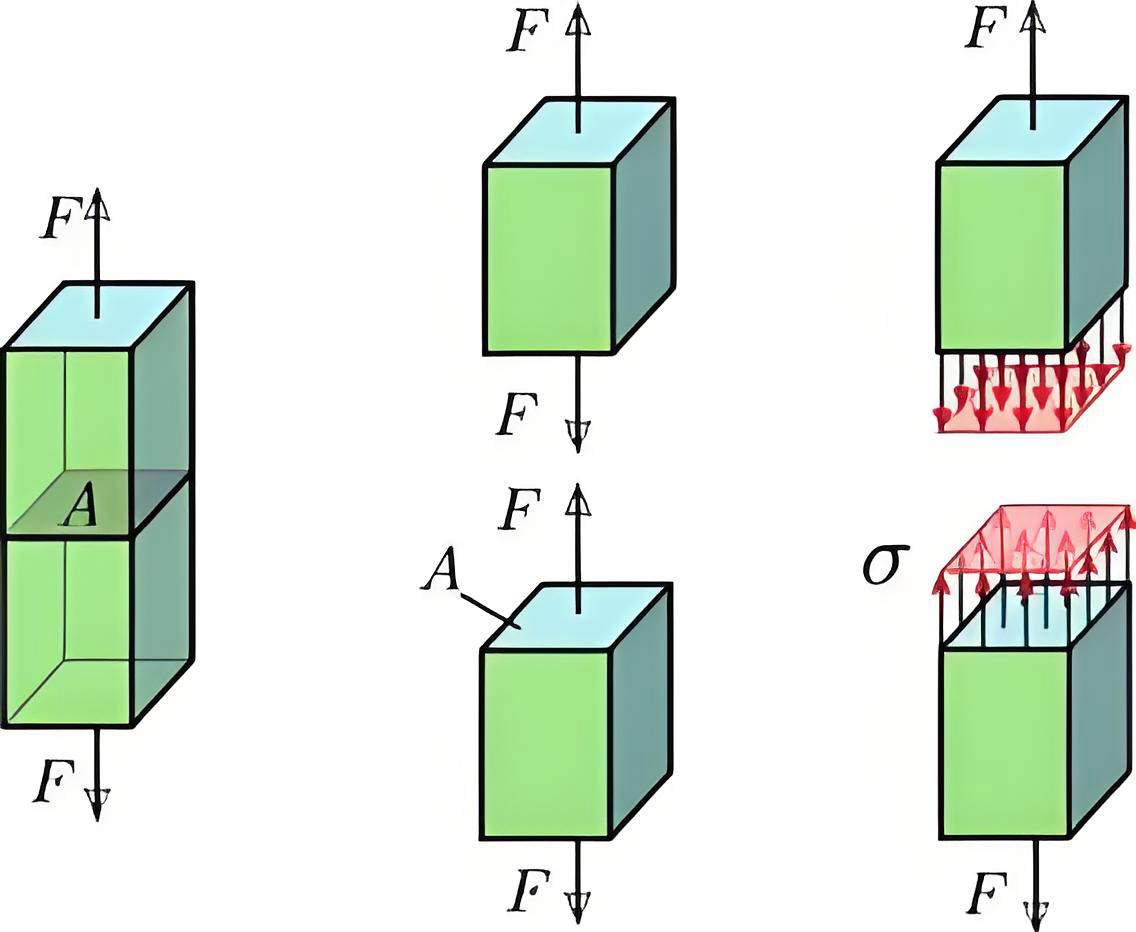

Tensile Stress vs Compressive Stress vs Yield Stress: Definition, Symbol, Formula, Area of Bolt, Difference & RelationMaterial strength is a foundation of engineering and design, and stress is defined as the internal resistance per unit a...View More >> -

Nov.06

2025

Tap Drill Size Chart & CalculatorA tap drill is one of the most important tools in any machine shop or metalworking environment. It’s used to create th...View More >> -

Oct.26

2025

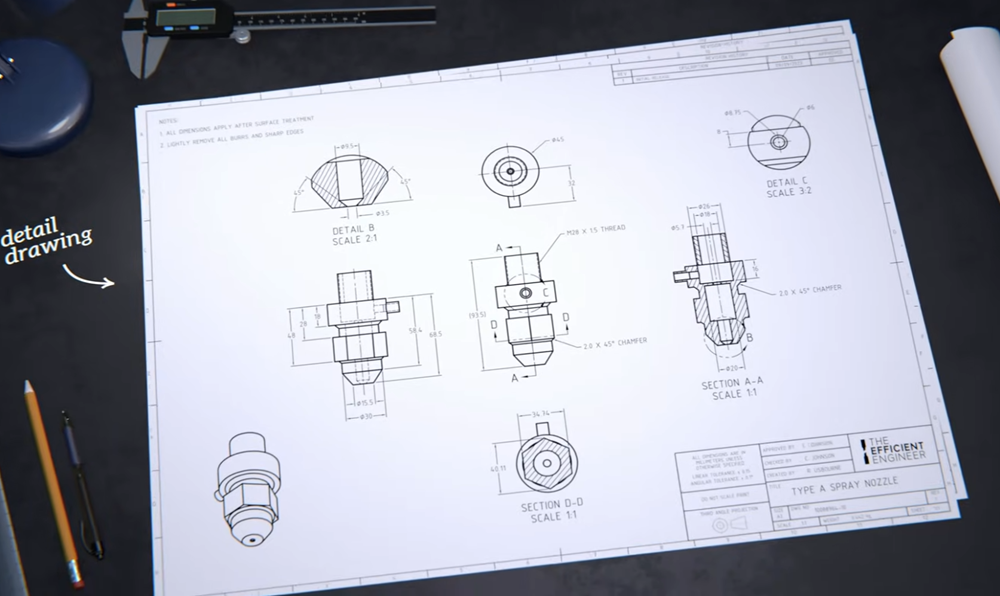

Engineering Drawing Abbreviations & Symbols | CSK, DRG, ASSY, A/F, SK, SQ Meaning in Technical DrawingEngineering drawings are a universal language in CNC machining and mechanical manufacturing. These technical documents a...View More >> -

Oct.22

2025

NSS vs AASS vs CASS Salt Spray Test, What’s the DifferenceHow can you ensure that your metal products or coated components won't rust or fail prematurely when exposed to humid, s...View More >> -

Oct.14

2025

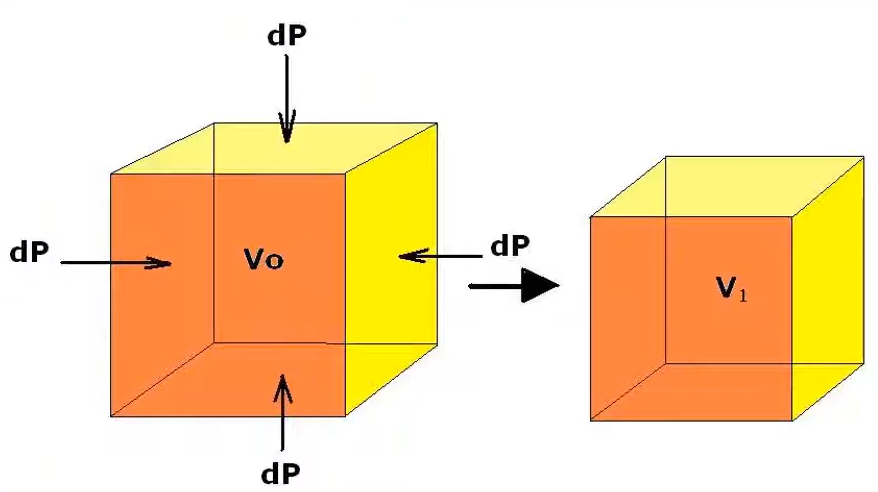

Shear Modulus vs Bulk Modulus: Definition, Symbol, Units, Formula, Calculate, Example, Difference & RelationMaterials deform in different ways depending on how you load them. Push equally from all sides and the volume shrinks; s...View More >> -

Oct.14

2025

VMC Machine Full Form vs CNC Machine Full Form, What’s the Difference?In modern manufacturing, precision and automation are key to efficiency, consistency, and high-quality output. Two terms...View More >> -

Oct.11

2025

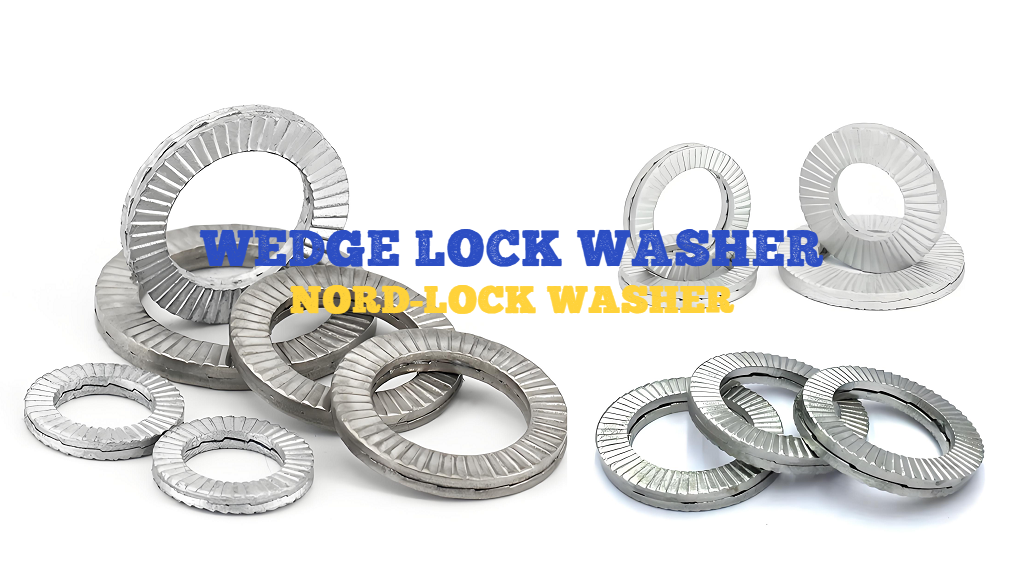

Wedge Lock Washer Use, Dimensions, Types, Torque, Standard, Price, Installation | Nord-Lock Washer ExplainedWedge lock washers, often called Nord Lock washers, are engineered fastener components designed to maintain bolt tension...View More >> -

Oct.09

2025

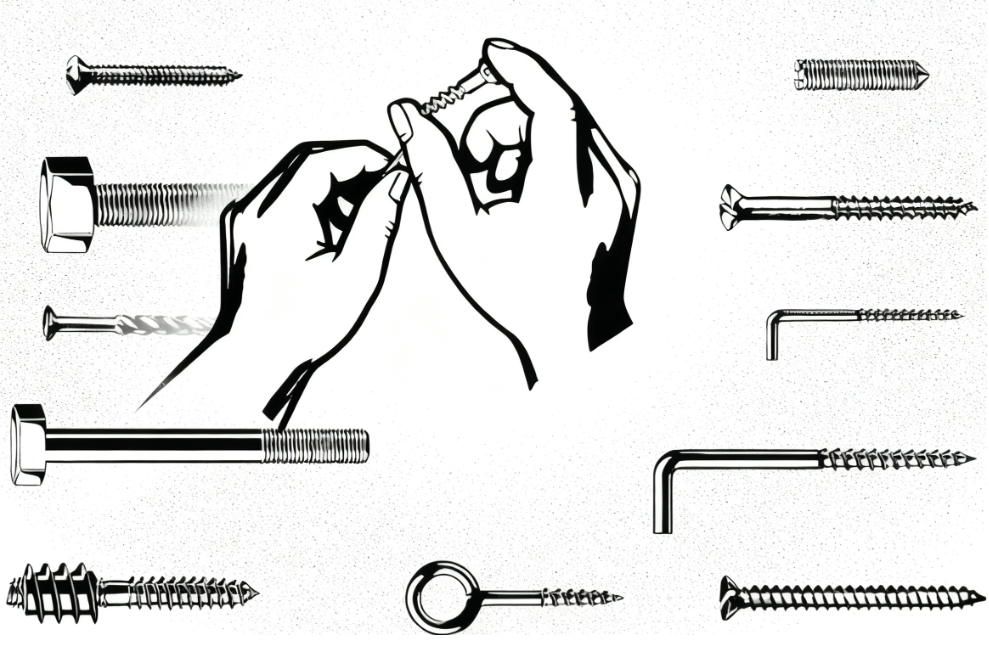

Nail Size Chart: Common Nail Sizes & How To ChooseNails are among the most essential fasteners in construction, woodworking, and furniture manufacturing — simple in app...View More >> -

Sep.12

2025

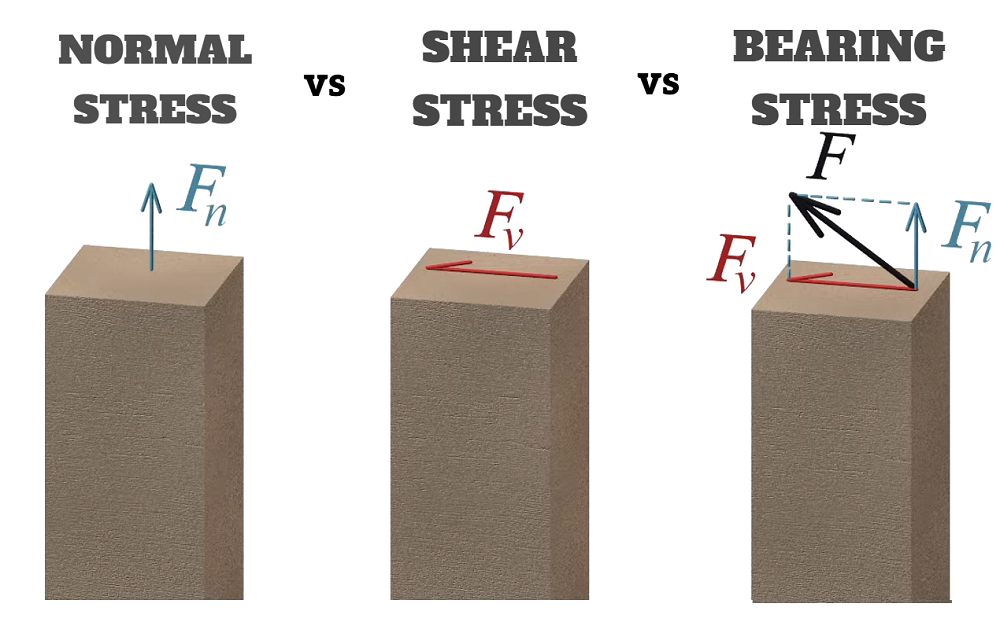

Bearing Stress vs Shear stress vs Normal Stress: Definition, Symbol, Units, Calculation Formula, Example & DifferenceStress is defined as the intensity of internal forces within a solid material and is a fundamental concept in engineerin...View More >> -

Sep.10

2025

Square Thread Definition, Diagram, Angle, Types, Size Chart, Calculation, Uses, Square vs ACME/V ThreadSquare threads are an important profile used in screws, nuts, and bolts designed for power transmission. Their unique sh...View More >>