With the continuous improvement of material performance requirements and the optimization of heat treatment processes, H13 steel has demonstrated unique value in industrial applications. As a hot-working tool steel, H13 belongs to the medium carbon chromium-molybdenum-vanadium alloy family. Due to its excellent balance of toughness, heat resistance, and wear resistance, it is known as the “universal hot work die steel.”

In this blog, we are going to present a comprehensive overview of H13 tool steel, covering its chemical composition, microstructure, mechanical and physical properties, heat treatment, equivalents, advantages and disadvantages, typical applications, pricing, and comparison with P20 tool steel.

Related Read: Mild Steel Composition, Properties, Grades, Uses, Types, Mild Steel vs Stainless Steel

What is H13 Tool Steel?

H13 steel, designated by the American Iron and Steel Institute (AISI) as a hot work tool steel, is also known under the Chinese grade 4Cr5MoSiV1. It is an air-hardening die steel that offers excellent toughness, thermal fatigue resistance, and hot hardness. The “H” represents hot work applications, and “13” indicates its position in the AISI hot work tool steel series.

H13 Steel Chemical Composition

H13 steel is made up of a combination of alloying elements that provide it with superior mechanical properties, thermal strength, and resistance to fatigue and wear. The main chemical composition is:

| Element | Content (%) | Function |

|---|---|---|

| Carbon (C) | 0.32 – 0.45 | Provides hardness and strength after quenching. Balanced carbon content improves toughness and wear resistance. |

| Silicon (Si) | 0.80 – 1.20 | Adds oxidation resistance, hardenability, and tempering stability. |

| Manganese (Mn) | 0.20 – 0.50 | Improves strength and hot workability. It also forms MnS instead of low-melting FeS, reducing the risk of hot shortness. |

| Chromium (Cr) | 4.75 – 5.50 | Increases corrosion resistance, hardness, and tempering stability, while improving high-temperature strength. |

| Molybdenum (Mo) | 1.10 – 1.75 | Strengthens steel at elevated temperatures and resists thermal fatigue. Also refines grain size. |

| Vanadium (V) | 0.80 – 1.20 | Forms stable carbides that enhance wear resistance, hot hardness, and toughness. |

| Nickel (Ni) | ≤ 0.25 | – |

| Phosphorus (P) | ≤ 0.030 | – |

| Sulfur (S) | ≤ 0.050 | – |

The combination of Cr, Mo, and V ensures H13 maintains strength and hardness at high temperatures. Mn and Si improve its hot workability and tempering stability, while P and S are controlled to maintain toughness and plasticity.

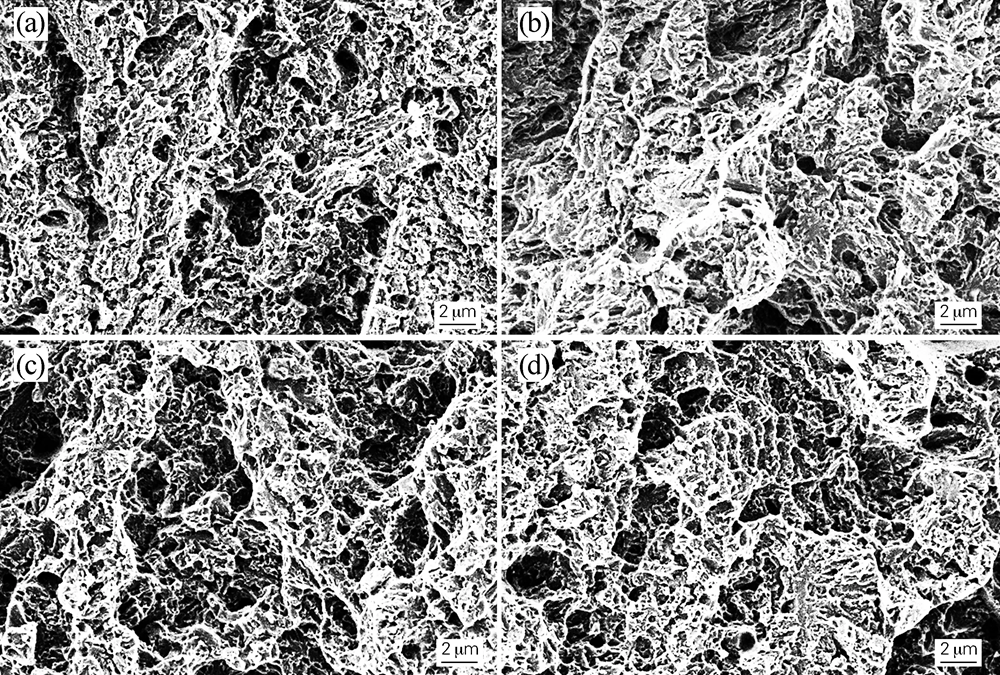

H13 Tool Steel Microstructure

The microstructure of H13 steel is a general term for its internal grain structure and inclusion distribution, which has an important influence on its performance:

- Grain structure – The grain structure of H13 steel is usually martensite after quenching. Martensite has high hardness and strength and is one of the main sources of H13 steel’s excellent performance.

- The size of the grain has a significant effect on the toughness and fracture resistance of the material. Usually, a fine grain structure helps to improve the toughness of the material.

- Inclusion distribution – Inclusions are carbides (mainly chromium carbides) formed in steel. Their distribution state has an important influence on the hardness, wear resistance and thermal stability of H13 steel.

Proper inclusion distribution can improve the hardness and wear resistance of the material, but too many or unevenly distributed inclusions may increase the brittleness of the material.

H13 Steel Material Properties

Hardness – Annealed State: ~229 HB, After Heat Treatment: 56–58 HRC

- Rockwell Hardness (HRC): After proper heat treatment: 56–58 HRC

- Tensile Strength: ≥1650 MPa

- Yield Strength: ≥1300 MPa

- Elongation at Break: – ≥10%

- Impact Toughness: ≥40 J/cm²

- Fatigue Strength: High, due to thermal fatigue resistance

- Fracture Toughness: Excellent, with stable performance at high temperatures

- Density: ~7.85 g/cm³ (7850 kg/m³ or 85 kg/dm³)

- Thermal Conductivity: ~23 W/(m·K)

- Thermal Expansion Coefficient: ~11.5×10^-6/°C

- Melting Point: ~1470°C

- Softening Temperature: ~800°C

- Heat Resistance: Maintains hardness of 48–52 HRC at 500–550°C, Working temperature should not exceed 540°C (~1000°F), as hardness declines above this point

H13 Steel Heat Treatment Process

The heat treatment process of H13 includes pre-heat treatment, quenching and tempering, and chemical heat treatment:

Pre-heat treatment:

The H13 steel and mold blanks supplied on the market have been annealed and heat treated in the steel plant to ensure good metallographic structure, appropriate hardness and good processability, and no annealing is required. However, if the manufacturer destroys the original structure and performance after re-forging, and increases the forging stress, re-annealing must be performed. The isothermal spheroidizing annealing process is: heating and holding at 860~890℃ for 2 hours, cooling to 740~760℃ for 4 hours, and furnace cooling to about 500℃ before taking out of the furnace.

Quenching and tempering:

Quenching process specifications for molds with good toughness: heating temperature 1020~1050℃, oil cooling or air cooling, hardness 54~58HRC.

Hot hardness-based mold quenching process specifications: heating temperature 1050~1080℃, oil cooling, hardness 56~58HRC.

Recommended tempering temperature: 530~560℃, hardness 48~52HRC; tempering temperature 560~580℃, hardness 47~49HRC. Tempering should be performed twice. When tempering at 500℃, a secondary hardening peak appears. The tempering hardness is the highest, with a peak value of about 55HRC, but the toughness is the worst. Therefore, the tempering process should avoid about 500℃.

Chemical heat treatment:

If H13 steel is gas nitrided or nitrocarburized, the mold can be further strengthened, but its nitriding temperature should not be higher than the tempering temperature to ensure that the core strength is not reduced, thereby increasing the service life of the mold.

Surface strengthening:

Nitriding, nitrocarburizing or PVD coating (such as TiN) can further improve the surface hardness (up to 60HRC or above) and wear resistance.

H13 Steel Machinability

H13 steel can achieve the required hardness and toughness through heat treatment, so it has good processing performance:

Forging: The forging temperature range is 1050 – 850℃, and the forging ratio should be not less than 3. During the forging process, attention should be paid to controlling the heating speed and deformation amount to avoid defects such as cracks to ensure uniform organization and good performance of the steel.

Cutting: 4Cr5MoSiV1 in the annealed state has good cutting performance. It can be processed with high-speed steel or carbide tools, and the cutting parameters should be reasonably selected according to factors such as tool material and workpiece hardness.

Electrodischarge machining: It is often used to process mold cavities with complex shapes. After electrodischarge machining, a metamorphic layer will form on the surface of the mold, and appropriate subsequent treatment, such as polishing, is required to improve the surface quality of the mold.

H13 Steel Weldability

Due to its high content of alloy elements, hot cracks and embrittlement are easily generated during welding, so welding is more difficult. But this does not mean that H13 steel cannot be welded. As long as the correct welding methods and precautions are mastered, H13 steel welding can be achieved.

Preheating: In order to reduce the thermal cracks and stress generated during welding, H13 steel needs to be fully preheated. The preheating temperature is generally controlled between 200-400℃, and the specific temperature should be adjusted according to the thickness of the steel and welding conditions.

Select suitable welding materials: In order to ensure the strength and toughness of the welded joint, welding materials with similar composition to H13 steel should be selected. At the same time, the selection of welding materials should also consider their crack resistance and wear resistance.

Slow cooling: After welding is completed, slow cooling should be adopted to avoid the formation of hardened structure and embrittlement. Slow cooling can be carried out by covering with insulation materials or placing in a furnace.

H13 Steel Sizes

The thickness of H13 die steel is usually between 8mm and 150mm, the width is between 1600mm and 3900mm, and the length can reach 6000mm to 14000mm. At the same time, it can also be rolled and cut according to customer needs.

H13 Tool Steel Equivalent Grades

Equivalent grades in other regions:

| Standard | Equivalent Grade |

|---|---|

| USA (AISI) | H13 |

| China | 4Cr5MoSiV1 |

| Germany | 1.2344 |

| Japan | SKD61 |

| Sweden | 8407 |

H13 Steel Advantages & Disadvantages

Pros:

- Excellent hot hardness and thermal fatigue resistance

- High hardenability and toughness

- Good wear resistance

- Strong tempering stability

- Low deformation during heat treatment

- Good machinability and weldability

Cons:

- Moderate corrosion resistance

- Hardness decreases rapidly above 540°C

- Medium resistance to decarburization

H13 Tool Steel Applications

Thanks to its high-temperature strength and toughness, H13 steel is widely applied in:

- Die casting die: aluminum alloy, zinc alloy die casting die (such as automobile wheel hub, engine housing die) – because of its good thermal fatigue performance, toughness and thermal conductivity, it can withstand the impact of high temperature, high pressure and high-speed metal liquid in the die casting process. It can be used to manufacture aluminum alloy, magnesium alloy, zinc alloy and other die casting dies to ensure the service life of the die and the quality of the casting.

- Hot forging die: medium carbon steel, stainless steel hot forging die (such as gear, bearing ring forming die) – can be used to manufacture various forging dies, such as hammer forging die, hot upsetting die, etc., can withstand the impact load and high temperature in the forging process, has good wear resistance and thermal fatigue resistance, helps to improve the service life of the forging die and reduce production costs.

- Extrusion dies: Copper alloy and aluminum alloy extrusion dies (such as profile extrusion nozzles and pipe dies) – can withstand high temperatures and high pressures during hot extrusion. Its good high temperature strength, toughness and thermal fatigue resistance can keep the mold in a stable size and shape during long-term operation, improving the quality and production efficiency of extruded products.

- Hot forming tools: used to make glass molds, plastic molds, etc., as well as some parts that work at high temperatures, such as hot shear blades, hot forging molds, etc.

- Other fields: used in electronic equipment production, military equipment manufacturing, automotive parts manufacturing and other industries, and can also be used to make cutting tools, steel quenching molds, precision molds, bearings, etc., and also in high-tech fields such as aviation, aerospace, and electrical appliances.

H13 Steel Price Per Pound

On average, in 2025, the price ranges from approximately $2.00 to $4.00 per pound when purchased in bulk, based on listings from platforms like Alibaba, Made-in-China, and Xometry, which quote prices between $1,000 and $3,500 per metric ton. Smaller quantities or retail purchases, such as through Amazon or Online Metals, can be significantly higher, sometimes exceeding $4.50 per pound. Prices are also influenced by market conditions, processing requirements, and alloy content (notably vanadium and molybdenum), as well as whether the steel is hot-rolled or cold-rolled. The price per pound of H13 steel varies significantly depending on the supplier, form, size, and other factors. For precise pricing, it is advisable to obtain quotes directly from multiple suppliers based on your specific needs.

H13 vs P20 Tool Steel: What are the Differences?

P20 and H13 steel are common mold materials, and they have some differences in composition, performance and use. We intend to compare the basic characteristics, mechanical properties, heat treatment capabilities and application areas of the materials in detail.

1. Basic characteristics of materials

P20 material, also known as pre-hardened plastic mold steel, is a medium-carbon, low-alloy steel. Its main alloying elements include chromium, nickel and molybdenum, which give P20 good hardenability and toughness. The moderate carbon content of P20 gives it good machinability during heat treatment.

H13 material, also known as hot work die steel, is a high-alloy steel. Its main alloying elements include chromium, molybdenum and vanadium, which give H13 good heat resistance, wear resistance and resistance to tempering softening. The low carbon content of H13 gives it good stability and oxidation resistance at high temperatures.

2. Mechanical properties

After pre-hardening, P20 material has high hardness and strength while maintaining good toughness and plasticity. This makes P20 have good wear resistance and impact resistance when manufacturing molds.

H13 material can still maintain high hardness and strength at high temperatures, and has good thermal fatigue resistance. This makes H13 suitable for manufacturing molds that withstand high temperature, high pressure and strong corrosive environments.

3. Heat treatment characteristics

P20 material has good hardenability and can obtain the required hardness and toughness through quenching and tempering. P20 has a small deformation during heat treatment, which is conducive to ensuring the accuracy and stability of the mold.

When heat treating H13 material, the heating temperature and cooling rate must be strictly controlled to prevent excessive stress and deformation. At the same time, H13 has good dimensional stability during quenching and tempering, which is suitable for manufacturing precision molds.

4. Application field

Due to its good mechanical properties, P20 material is widely used in thermoplastic plastic injection molds, extrusion molds, etc. In addition, P20 can also be used to manufacture some parts with high requirements for wear resistance and toughness.

H13 material is mainly used to manufacture hot forging dies, die casting dies, hot extrusion dies and other dies that withstand high temperature and strong corrosive environments due to its excellent high temperature performance, wear resistance and tempering softening resistance. In addition, H13 can also be used to manufacture some parts that require high thermal fatigue resistance.

FAQs of ANSI H13 Tool Steel

Is H13 Steel Good for Knife Making?

H13 steel can be used to make knives, but it is not ideal. While it offers industrial-grade toughness, its hardness (~55 HRC) and wear resistance are lower than professional knife steels, and its cutting edge retention is poor.

Is H13 Steel Magnetic?

Yes, H13 steel is magnetic. Magnetic testing can be used as a preliminary identification method, but it cannot confirm the exact chemical composition.