Due to its excellent properties, Mild Steel (MS material) has become a sought-after material in many industries. It has unparalleled weldability and machinability, which has led to an exponential increase in its usage. Today, we will discuss what mild steel is, how it’s made, its composition, properties (hardness, density, melting point, strength, etc.), grades, types, uses, gauge chart, and differences with stainless steel. Read till to the end for better understanding.

What is Mild Steel?

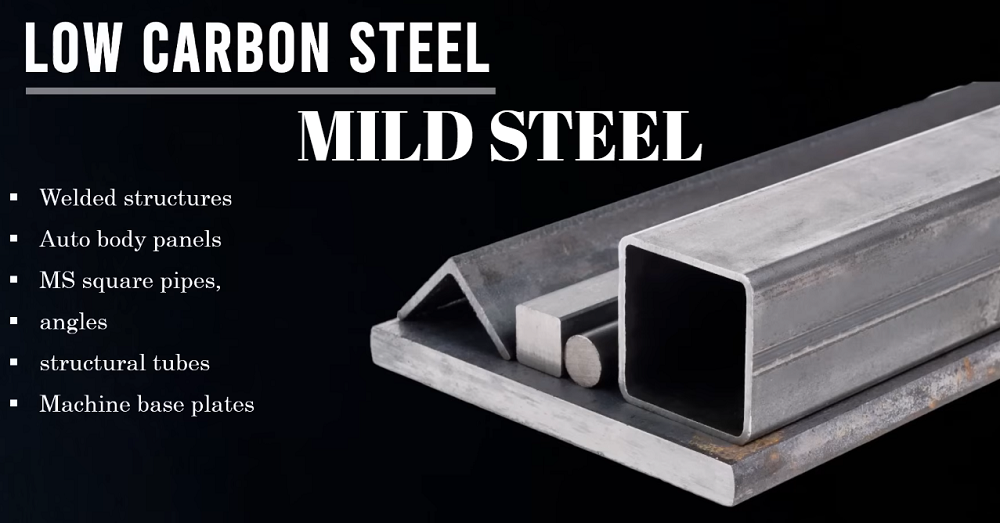

MS material full form – Mild Steel, is a type of carbon steel with a low amount of carbon, which enhances the properties of pure iron. It is also known as low carbon steel, soft steel, or plain carbon steel. Low carbon steel is one of the largest groups of carbon steel, with shapes including bars, tubes, sheets, and structural beams. MS carbon content varies depending on the requirements of the steel, and it is in the range of 0.04% – 0.3%. Mild steel is not an alloy steel and therefore does not contain large amounts of other elements besides iron. You will not find a vast amount of molybdenum, chromium, or other alloying elements in mild steel.

How is Mild Steel Manufactured?

The manufacturing processes of mild steel are similar to those of other carbon steels. In modern manufacturing processes, three major steps are involved in producing mild steel out of pure iron or iron ore. They are:

- Step 1. Primary steel making process – Once the coal and iron ore are extracted from the earth, they are mixed together and heated in a blast furnace. Modern primary steel making uses modern furnaces such as a basic oxygen furnace or an electric Arc furnace.

- Step 2. Secondary steel making process – Once the steel is melted, the mixture is moved to another furnace to burn off any impurities they may contain. The purpose of secondary steel making is mainly to reduce the carbon content to the desired extent and add other alloying elements to improve the properties of the steel. Manipulating the furnace conditions, such as the temperature, cooling rate, etc,. also aid this process.

- Step 3. Casting and primary forming process – Once the steel has attained the specific carbon content and mechanical properties that improve its performance, the molten steel is poured into a mold and allowed to solidify. This slab of mild steel is then brought down to the desired shape and size using the process of hot rolling or cold drawing, etc.

Mild Steel Microstructure

Low-carbon steel refers to carbon steel with a carbon content of less than 0.25%. Its typical structure consists of ferrite and a small amount of pearlite. This structure arises from the low carbon content, which allows for sufficient carbon diffusion during the austenite transformation. Upon cooling, a two-phase mixed structure is formed, with a soft ferrite matrix (hardness approximately 80-100 HB) and a hard pearlite dispersed phase (hardness 200-250 HB). Scanning electron microscopy reveals that ferrite grains typically range from 10-30 μm in size, and the proportion of pearlite increases with increasing carbon content. For example, pearlite accounts for approximately 5% in 0.1% carbon steel and rises to 15% in 0.2% carbon steel (data source: Metallurgy and Heat Treatment, 6th edition).

Mild Steel (MS) Chemical Composition & Structure

The core components of common carbon steel commonly used in the market include:

- Iron (Fe): Comprising over 98% of steel, it is a matrix element and determines the material’s metallic properties.

- Carbon (C): Its content is typically between 0.04% and 0.3%. Lower carbon content improves the steel’s plasticity and toughness, but also reduces its hardness.

- Manganese (Mn): Its content is approximately 0.30% to 0.70%, enhancing the steel’s strength and hardenability.

- Silicon (Si): Its content is ≤0.40%, serving as a deoxidizer and improving mechanical properties.

- Sulfur (S) and Phosphorus (P): Both are harmful impurities and their contents must be strictly controlled below 0.05%. Excessive amounts can lead to hot or cold brittleness.

The low carbon content means that mild steel is typically more ductile, machinable, and weldable than high carbon and other steel; it can be cut, machined, and formed into intricate shapes without adding proportional stresses to the workpiece. However, it also means that it is almost impossible to harden and strengthen through heating and quenching. It has lower tensile strength compared to high carbon steel and alloy steel. This is because of its very little carbon and other alloying elements to block dislocation in its crystal structure. This lack of alloying elements, such as those found in stainless steel, means that the iron in mild steel is subject to rust if not properly coated. It is the affordability, weldability, and machinability that make it such a popular choice for consumers.

Depending on the desired properties, other elements can be added or increased. For example, with drawing quality steel, the carbon content is kept low and aluminum is added. For structural steel, the carbon level is higher, and the manganese content is increased.

Mild Steel Properties

1. Mild Steel Mechanical Properties

Hardness of Mild Steel

- Brinell hardness (HB): 100-130. commonly found in mild steels with a carbon content of 0.13%-0.20%.

- Vickers hardness (HV): 90-150. which is equivalent to the HB value (HV ≈ HB × 0.95).

- Rockwell hardness (HRC): Mild steel is generally not suitable for HRC testing because its hardness falls below the lower limit of the HRC range (approximately HRC 20).

Strength of Mild Steel

The strength of mild steel (carbon content ≤ 0.25%) is primarily determined by its microstructure and processing. Typical mechanical properties are as follows:

- Yield strength: Typically 185-300 MPa (ASTM A36 standard), which can be increased to over 350 MPa through cold rolling or normalizing.

- Tensile strength: Ranges from 300-450 MPa and is directly related to the ferrite-pearlite ratio. For example, the tensile strength of Q235 steel is 375-500 MPa (GB/T 700-2006).

- Strengthening Mechanisms: Grain refinement (yield strength increases by 15-20 MPa for every grain refinement level) and solid solution strengthening (such as the addition of manganese and silicon) are the primary methods.

Toughness of Mild Steel

Toughness is a key indicator of low-carbon steel’s fracture resistance under dynamic loads and is primarily measured by the following parameters:

- Impact Energy: In the Charpy V-notch test, the impact energy of low-carbon steel at room temperature is typically ≥27 J (e.g., EN 10025 S235JR), dropping to 15-20 J at low temperatures (-20°C).

- Fracture Toughness (KIC): Approximately 50-100 MPa·m¹/², superior to high-carbon steel but lower than medium-alloy steel.

- Toughening Methods: Controlling sulfur and phosphorus content (≤0.05%) or refining grain size through normalizing can increase toughness by 20%-30%.

2. Mild Steel Physical and Chemical Properties

- Density of MS: Low carbon steel typically has a density of 7.85 g/cm³ (or 7850 kg/m³). (data source: American Society for Testing and Materials ASTM A370 standard).

- Thermal Conductivity of MS: Approximately 46-58 W/(m·K). The thermal conductivity of low-carbon steel is lower than that of copper (approximately 398 W/(m·K)) and aluminum (approximately 235 W/(m·K)), but higher than non-metallic materials such as plastic and wood. Its thermal conductivity is primarily influenced by its carbon content; higher carbon content (e.g., high-carbon steel) generally results in better thermal conductivity.

- Melting Point of MS: Between 1420°C and 1500°C. This range is lower than the melting point of pure iron (1535°C), which is consistent with the rule that the melting point of alloys is generally lower than that of their constituent elements.

- Conductivity of MS: The conductivity of mild steel is 3-4 times that of ordinary steel, mainly due to its low carbon content (less than 0.2%), which retains the metallic crystal properties of iron and conducts electricity through free electrons.

- Thermal Expansion of MS: 11.7×10⁻⁶/℃ to 12.5×10⁻⁶/℃.

3. Processing Properties

- – Plasticity: Elongation ≥ 20% (GB/T 700 standard), easily adaptable to cold working such as stamping and bending.

- – Weldability: Low carbon equivalent (CE) (typically <0.4%), less prone to cracking during welding, widely used for welding steel structures.

- – Machinability: Low hardness (HB ≤ 120), but prone to tool sticking, requiring optimized tool parameters.

Mild Steel Grade Chart (Standards)

Typical grades of MS (low carbon steel) in global regions are:

| Grade | Standard / Region | Description / Typical Use |

|---|---|---|

| MS (Mild Steel) | Indian Market | General purpose mild steel used widely in India. |

| AISI 1010 / 1008 | AISI (USA) | Very low carbon steel; deep-drawing parts and automotive panels. |

| ASTM A36 | ASTM (USA) | ~0.25% carbon; used in general structural frameworks. |

| SS400 | JIS (Japan) | Common in Japanese drawings; general structural use. |

| SPHC | JIS (Japan) | Used in sheet metal; very low carbon, good for forming. |

Mild Steel Uses (Applications)

Mild steel is widely used in industries; it is the most common type of metal used around us. Typical examples of where it is used in the world include:

- Construction & Infrastructure Industry: Used in rebar (such as HRB400) and profiles, accounting for approximately 50%. Also use in pipes, tubes, fencing, wire manufacturing, and signposts, etc.

- Automotive Manufacturing: Body panels (08Al steel) and chassis require high formability, with low-carbon steel accounting for 30%-40%. Its excellent cold formability and weldability meet the various requirements of the automobile manufacturing process.

- Household & Hardware: Cooking wares, screws, tubes, rivets, wire, etc., utilize its low cost and ease of processing.

- Machinery: Widely used in the manufacture of chains, rivets, bolts, shafts, and other parts that do not require high strength and hardness, such as drive shafts and connectors.

- Container Manufacturing: Due to its excellent corrosion resistance, mild steel is also commonly used to manufacture containers that need to withstand corrosive environments, such as oil and gas tanks.

Mild Steel Types

Main types of low carbon steel:

- Classification by use:

Structural low carbon steel: Mainly used in building structures and bridges, etc., requiring good plasticity and toughness to withstand dynamic loads and impact loads.

Mechanical low carbon steel: Used to manufacture mechanical parts, such as shafts, gears, etc., requiring good cutting performance and low hardness. - Classification by quality:

Ordinary low carbon steel: High sulfur and phosphorus content, easy to cut, but low plasticity and toughness.

High quality low carbon steel: Low sulfur and phosphorus content, high plasticity and toughness, often used to manufacture important parts.

Mild Steel Gauge Chart

Mild steel is commonly formed into sheets, tubes, plates, bars, beams, and other shapes to suit various applications, with mild steel sheet being the most widely used. Therefore, we believe it’s worth discussing the Mild Steel Gauge. Gauge is a standard unit of measurement for the thickness of a mild steel sheet. The lower the gauge number, the thicker the material; the higher the gauge number, the thinner the material. The Mild Steel Gauge Chart allows for quick conversions and provides a reference when specifying material thickness for sheet metal manufacturing projects.

Mild Steel Gauge Thickness Reference Chart

| Gauge Number | Inches | MM |

|---|---|---|

| 7 | 0.179 | 4.55 |

| 8 | 0.164 | 4.17 |

| 9 | 0.149 | 3.80 |

| 10 | 0.135 | 3.42 |

| 11 | 0.120 | 3.04 |

| 12 | 0.105 | 2.66 |

| 14 | 0.075 | 1.90 |

| 16 | 0.060 | 1.52 |

| 18 | 0.048 | 1.21 |

| 20 | 0.036 | 0.91 |

| 22 | 0.030 | 0.76 |

| 24 | 0.024 | 0.61 |

| 26 | 0.018 | 0.45 |

| 28 | 0.015 | 0.38 |

Mild Steel vs Stainless Steel: What are the Differences & Which is Better?

What’s the difference between stainless steel, another widely used steel, and mild steel? Which one is better? Let’s compare them:

Composition

Mild steel, also known as low carbon steel or soft steel, mainly consists of iron and carbon with a carbon content between 0.05% and 0.25%. It can be classified as dead mild steel, medium carbon steel, or high carbon steel. Besides iron and carbon, it may contain small amounts of nickel, chromium, aluminium, phosphorus, sulphur, and silicon.

Stainless steel, sometimes referred to as inox steel, contains iron and a minimum of 11% chromium. There are more than 150 grades of stainless steel, but about 15 are most commonly used. Along with iron and chromium, it can also include carbon, nickel, copper, silicon, nitrogen, manganese, and molybdenum.

Corrosion Resistance

Mild steel is not resistant to corrosion. When exposed to moisture and air, iron in mild steel reacts with oxygen to form iron oxide, commonly known as rust. To prevent rusting, mild steel is often coated by galvanizing or painting.

Stainless steel, on the other hand, does not rust easily. The presence of chromium helps the steel form a layer of chromium oxide when exposed to oxygen, which prevents iron from oxidation. This makes the metal naturally resistant to corrosion.

Fabrication

Mild steel can be cut, bent, twisted, machined, punched, drilled, welded, forged, and rolled with ease, making it a popular material in manufacturing and construction.

Stainless steel is not as easy to fabricate. Its toughness and composition can make processes like cutting and welding more challenging.

Aesthetics

Mild steel usually has a dull appearance and is not considered visually attractive.

In contrast, stainless steel features a silver-white, shiny surface that is often chosen for its bright and clean look.

Cleaning & Maintenance

Cleaning and maintaining mild steel can be difficult due to its tendency to rust and corrode.

Stainless steel can be cleaned easily and requires less maintenance, making it suitable for hygienic environments.

Weldability

Mild steel is easier to weld and work with, even for less experienced welders.

Stainless steel has lower weldability and usually requires very skilled and experienced welders for best results.

Strength and Magnetization

Mild steel has less strength compared to stainless steel. It contains a high amount of iron, which allows it to be permanently magnetized and display strong magnetic properties.

Stainless steel provides more strength. Some types, like ferritic stainless steel, are magnetic, but others, such as austenitic stainless steel, cannot be magnetized.

Ductility

Mild steel, with its low carbon content, is more ductile and can undergo significant plastic deformation without cracking or breaking. This allows mild steel to be shaped and formed easily. Stainless steel, in comparison, is less ductile.

Malleability

Mild steel is much more malleable, meaning it can be hammered or rolled into thin sheets more easily. Stainless steel is less malleable.

Toughness

Toughness is the energy required to break a material. Mild steel is less tough, while stainless steel is tougher, making it better suited for applications where impact resistance is important.

Brittleness

Mild steel is less brittle, so it is less likely to crack under stress. Stainless steel, on the other hand, is more brittle.

Lifespan and Cost

Mild steel has a shorter lifespan and requires less finishing, making it less expensive and a better option for projects with a low budget. Stainless steel offers a longer lifespan, but the cost of finishing and the material itself is higher.

Which is Better?

The better choice depends on your needs. If you need a material that is easy to fabricate, weld, and is cost-effective for structural applications, mild steel is a practical option. For projects requiring corrosion resistance, a clean appearance, easier cleaning, and low maintenance, stainless steel is recommended. Each material offers unique advantages for different applications, so the decision should be based on the demands of your project.