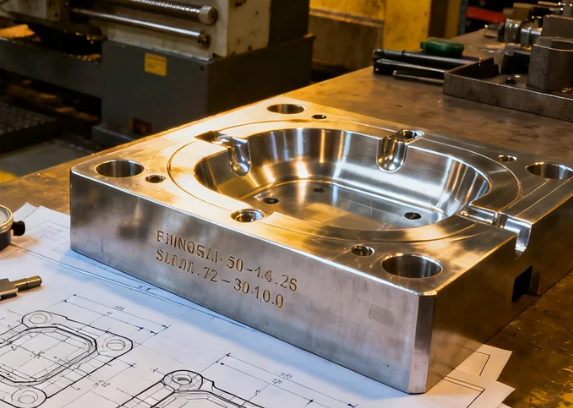

Mold design and engineering is the process of creating and developing molds used to shape and produce plastic or metal parts with precision and consistency. It involves designing the mold’s cavities, cores, cooling channels, ejection systems, and gating mechanisms to meet specific product requirements, material properties, and production volumes. Skilled engineers use CAD software, mold flow analysis, and prototyping to optimize part manufacturability, ensure dimensional accuracy, and minimize defects. Effective mold design and engineering not only improve product quality but also enhance production efficiency, reduce costs, and extend the lifespan of the molds.