What are the advantages and disadvantages of die casting?

Advantages:

- It produces a wide variety of parts repeatedly with excellent dimensional stability and extremely close tolerances

- It can produce complex parts in diverse sizes, shapes and intricacies

- Die casting parts are lightweight, heat resistant and have high strength

- It requires minimal secondary operations

- It offers broader range of shapes and components than any alternative processes

- It offers lower part cost and quicker delivery than alternative processes due to its high production efficiency

- It provides both smooth or textured surface

- It offers varieties of machining and finishing options with minimum operation.

Disadvantages:

- Die casting may not be able to produce parts that need to be made of certain alloy

- Die casting requires upfront toolings which may take several weeks depending on your part designs and production volumes. If your parts are not in regular production yet but you want them shipped within several days after your initial order, die casting may not be the option.

How do I know if die casting is right for my project?

Do you require complex shapes?

If you do, die casting may be your best choice since it allows for more complex designs and tighter tolerances than stamping or other methods.

Do you require individualized customization for your parts?

One advantage of die casting is once the parts are die cast, they can be easily customized individually by adding finishes, textures, fastening elements or other additions. This makes die casting the best option for smooth-running, high volume assembly for varieties of complex, customized parts.

Is your production volume high?

If you need to produce more than 100 parts a day, die casting is the ideal option since it makes parts fast – it can churn out thousands of multiple parts at once – and can really ramp up your company’s efficiency.

Do you require high strength for your part?

Different manufacturing processes lead to different part strength. For example, parts that are produced with plastic injection molding or put together by welding or other joining processes will surely have poorer part strength. Die casting produces one integrate, solid piece hence ensures higher part strength.

How does the die casting process work?

1. A steel mold, often called “die“, must be prepared upfront. The die must be made in at least two sections to allow removal of the die cast parts. These die sections are mounted securely and clamped tightly together in the die casting machine and are arranged to make sure one is stationary (fixed die half) and the other is moveable (injector die half). Safety interlock systems are used to prevent the die halves from opening during the die casting process.

2. Under high pressure, molten metal is forced into the die cavity and solidifies quickly. The two die halves will then be drawn apart and the die cast part is ejected.

Compared to alternative manufacturing processes, die casting is known as the fastest process for producing precise non-ferrous metal parts. Depending on the die cast part complexity, die casting dies can be very simple, or more complex with removeable slides, cores or other sections.

How does a hot chamber die casting machine work?

Hot chamber machines are used mainly for zinc alloys and other alloys with low melting point.

These alloys, when melted, do not readily erode metal pots, cylinders, plungers, and other steel working parts of the die casting machines. With modern tecnnology, hot chamber machines are increasingly used for magnesium alloys as well.

Operating process of the hot chamber machines:

- Die cavity is closed.

- Plunger is raised and a port opens, the molten metal will then fill the gooseneck cylinder

- Plunger moves downward, seals the port and forces molten metal through gooseneck passage and nozzle and into the die cavity.

- Molten metal solidifies in the die cavity.

- Die opens and cores, if any, retract. Die cast part stays in the ejector die.

- Plunger is withdrawn, pulling molten metal back through nozzle and gooseneck.

- Ejector pins push die cast part out of the ejector die.

Hot chamber die casting produces tight tolerance parts with fine details and high strength high production rates. Depending on part size and complexity, its cycle times vary from less than 1 sec to 30 seconds.

How does a cold chamber die casting machine work?

The main difference between cold chamber and hot chamber machines is: cold chamber machins’ injection plunger and cylinder are not submerged in molten metal – This minimizes the contact between the molten alloy and the metal pots, cylinders, plungers, and other steel working parts of the die casting machines. With modern tecnnology, hot chamber machines are increasingly used for magnesium alloys as well.

Cold chamber machines are primarily used for aluminum, brass, larger magnesium die casting parts and other alloys with high melting temperature.

Operating process of the cold chamber machines:

- Die cavity is closed.

- The molten metal is poured into a “cold chamber” through a port or pouring slot by hand or automatic ladle.

- A hydraulically operated plunger moves forward and seals the port or slot, forcing molten metal into the locked die at high pressures.

- Molten metal solidifies in the die cavity.

- The plunger is withdrawn, the die opens, the resulting die cast part is then ejected

In cold chamber die casting, excess metal, as part of the complete shot, is ejected along with the die cast part. This is due to excess molten metal is poured into the cold chamber in order to maintain sufficient presssure to pack the die cavity solidly with casting alloy.

Which types of die casting dies are there?

There’re several types of die casting dies:

- Single cavity die means the die only has one cavity.

- Multiple cavity die means the die has several cavities of identical shapes.

- Family cavity die means the die has several cavities of different shapes. It is normally used to manufacture several parts of the same assembly.

- Unit die means the combination of several interchangeable cavity blocks of different shapes. This enables fast changing of cavity blocks while still in a common holder and several parts of the same assembly or of different customers can be cast at the same time. Unit die is mainly used to improve production economies.

What are the advantages of die casting with aluminum alloys?

Aluminum die castig provides significant advantages over any alternative processes and metal alloys, such as:

It’s ideal for creating very lightweight products in various shapes and sizes with superior strength, stiffness, resilience and durability

It retains maximum dimensional accuracy and stability for even complex designs and thin-wall products

Great corrision resistance and mechanical properties make die cast aluminum a primary choice for various demanding applications

Exceptional thermal conductivity and heat dissipation properties, and can withstand the highest temperatures among all die cast alloys

Non-magnetic with excellent electrical conductivity and EMI/RFI shielding properties make them ideal to use in electronic products

Easy to be machined for very high precision requirements (normally no machining is required due to the tight tolerance of aluminum die cast parts)

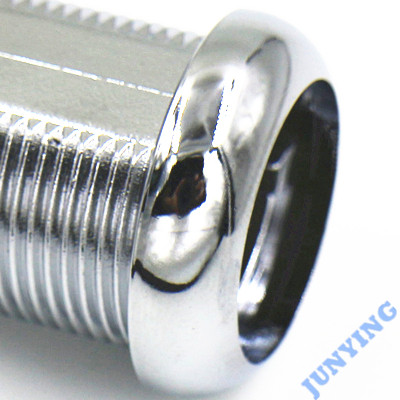

Great finishing characteristics offer a wide variety of finishing options (polishing, anodizing, chromating, painting, powder coating, plating, …).

Cost effective: more economical than alternative casting processes or metal alloys

Long Tooling life: Aluminum die casting tooling usually lasts for 50-400k shots depending on the design

Higher production rates: Aluminum die casting process allows high volume parts to be manufactured much more quickly than any other alternative processes or metal alloys. At Cofly, we utilize several automated work cells to further increase our production rates.

Green and sustainable: over 95% aluminum die castings use post-consumer recycled aluminum. The aluminum die cast tools and parts can also be easily recycled.

What are the advantages of die casting with zinc alloys?

Zinc die casting’s characteristics give it unique advantages over alternative processes and other metal alloys, such as:

It’s ideal for high precision manufacturing of miniature or small complex parts and components

Superior castability: low melting point & exceptional fluidity make zinc alloys the easiest metals to cast;

Faster cycle times: high castability allows for higher production rates

Long tooling life: due to the lower melting temperatures used, zinc die casting tooling can last for 400k-1 million shots depending on the design

Cost effective: low raw material cost, energy-saving process and long tooling life make zinc die casting very economical

Superior hardness, ductility and impact strength make die cast zinc an ideal alternative for stamped, pressed, fabricated and machined parts.

High structural integrity, dimensional accuracy and stability are optimal for complex, thin-wall products requiring most intricate details

Mechanical properties often exceed other die cast alloys such as aluminum, magnesium, cast irons and bronze.

Non-magnetic with excellent electrical conductivity and EMI/RFI shielding properties

Highly durable, great corrision resistance and self-lubricating properties

Excellent thermal & electrical conductivity

Great finishing characteristics offer a wide variety of finishing options (polishing, anodizing, chromating, painting, powder coating, plating, …).

Easy to be machined for very high precision requirements

Ability to cold form for easy joining

Green and sustainable: low casting temperatures provide considerable energy savings; also the die cast zinc parts are completely recyclable

What are the materials junying uses for die casting?

ADC12 ADC10 A360 A380 ENAC-43400

What prototyping services does junying provide for die casting?

junying can assist on your initial part design & material selection, they’ll also provide thorough DFx, value engineering analysis and design optimization suggestions to improve your part’s cost performance, functionality, manufacturability and time-to-market schedule.

Depending on your design requirments, we can make your prototypes utilizsing the following techniques:

- The latest 3D printing

- Machining

What is the die casting part size junying can produce?

For aluminum die casting, we can manufacture parts as small as a few grams up to 2 kilograms.

For zinc die casting, we are able to manufacture parts as small as one hundredth of a gram up to 0.6 kilogram.

What is the minimum wall thickness of your aluminum and zinc die castings?

In general, the optimum wall thickness is 0.04” to 0.12”.

However, the minimum or maximum wall thickness, especially cross-sectional wall thickness, depends on the overall size and design of the part.

What surface treatments and finishings do you provide for die cast parts?

junying provides full range of surface treatment and finishing service, including deburring, shot blasting, cleaning, painting, powder coating, all kinds of plating, e-coating, and many more.

Can die cast parts be welded?

No. Due to the nature of the alloy, welding will destory the part.