Tesla has made a technological breakthrough in integrated die-casting. Through this technology, Tesla can die-cast almost all complex underbody parts of electric vehicles into a whole, instead of only die-casting about 400 parts. This technology will halve Tesla’s production costs or change the traditional way of manufacturing electric vehicles.

The Impact of Integrated Die-Casting on Tesla

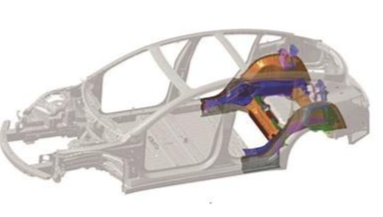

The impact of integrated die-casting on Tesla Tesla proposed integrated die-casting technology in 2019, pioneering the industry’s large-scale high-pressure casting; in September 2020, Tesla mass-produced this technology in the Model Y rear floor. The cost reduction and weight reduction effects are significant; in May 2021, Tesla’s front cabin assembly was successfully developed and applied to the Model Y model in October; the new version of Model 3, which will be launched in September 2023, adopts integrated casting; the subsequent Cybertruck will be launched Integrated die-casting is also applied; on the Investor Day in March 2023, Tesla proposed the “unboxing process” and changed the original car serial production line to a serial + parallel production line, that is, decomposing the car into components, and each component Assembled in parallel and finally assembled together, production costs can be reduced by 50%. If the Reuters report is true, Tesla’s one-piece die-casting may usher in a new breakthrough, or all chassis parts may be die-cast as a whole. If this technology is realized, it will further increase the application scope and value of single vehicles, and further reduce the cost of automobile manufacturing. , one step closer to realizing affordable electric vehicles.

National Policy Strongly Supports Integrated Die-Casting

National policies strongly support integrated die-casting. Since integrated die-casting can significantly reduce manufacturing costs and improve production efficiency, it will be an important trend in the future automotive industry and is also strongly supported by domestic policies. In April this year, the Ministry of Industry and Information Technology and other three departments issued guidance on promoting the high-quality development of the casting and forging industries, focusing on the industrial application of advanced processes and technologies such as integrated die-casting and forming in 2025, marking the first time that integrated die-casting has ushered in the country as a specific technology. level policy guidance and promotion. From the perspective of the domestic industry, since 2022, vehicle manufacturers and auto parts companies have increased their investment in die-casting equipment, and are currently gradually completing audits and preparations for mass production. As the layout is gradually completed, production capacity is expected to be gradually released, and the integrated die-casting industry space Expect to open quickly. Subsequently, as models equipped with integrated die-casting are gradually launched on the market, and the cost of car companies drops, it is expected to force other OEMs to apply integrated die-casting technology, driving its penetration rate in downstream car companies and body parts to gradually increase. According to relevant brokerage research reports, the number of integrated die-casting vehicles may increase significantly in 24-25 years, and the global penetration rate of integrated die-casting for new energy vehicles may increase from 6% to 12% in 21-25 years. Driven by integrated die-casting, the related industry space will reach 12.6 billion yuan in 25 years, with a CAGR of 104% from 2021 to 2025. As an important trend in the automotive industry, integrated die-casting is expected to enter the 1-10 large-scale stage in the next two to three years. It also means the birth of a new growth track for the capital market, which is worth tracking and paying attention to.

Integrated Die-Casting Related Industry Chain Review

Integrated die-casting technology is an important process for realizing automobile lightweighting. It has significant advantages in cost reduction and efficiency improvement. Driven by policy support and downstream demand, the industry trend is clear. Since 2022, vehicle manufacturers and auto parts companies have increased their investment in die-casting equipment. As the layout is gradually completed, production capacity is expected to be gradually released, and the integrated die-casting industry is expected to enter the 1-10 volume expansion stage.