Do you know about liquid metals? According to reports, liquid metal has the characteristics of fatigue resistance, high strength, high hardness, high elasticity, and high corrosion resistance. It can be used to make phone casings, folding screen hinges, car door locks, golf clubs, gypsum boards, bearings, etc. Why can liquid metal be so counterintuitive? Why is liquid so “high-strength”? How can liquid still be applied to a phone case? Aren’t you afraid of falling apart with just a touch?

Liquidmetal Guide: Compositions, Densities, Advantages & Applications

Liquid metal may not have been “liquid” before. Liquid metal refers to an amorphous metal, which can be regarded as a mixture of positive ion fluid and free electron gas. Liquid metal is also an amorphous and flowable liquid metal, which is a collective term for a series of low melting point metals and alloy materials. It is liquid at room temperature or lower heating temperatures and has both fluidity. It has strong conductivity, high hardness, corrosion resistance, high thermal conductivity, and high wear resistance.

Compositions of Liquid Metals

Liquid metal, also known as low melting point metal, refers to a metal that is liquid at room temperature or higher. In the science fiction film Terminator, the omnipotent robot is made of liquid metal.

Low melting point metals are a magical material. Among the 118 elements that exhibit periodic behavior, non-metals only account for 22, while metals account for as many as 96. However, among so many metals, only a few are in liquid state at room temperature, such as element 31 gallium (Ga, melting point 29.76 ℃), element 37 rubidium (Rb, melting point 38.89 ℃), element 55 cesium (Cs, melting point 28.44 ℃), element 80 mercury (Hg, melting point -38.86 ℃), and element 87 francium (Fr, melting point 27 ℃). The melting points of other metals are mostly in the hundreds of degrees Celsius or even higher. In addition, there are a few types of alloys, such as sodium potassium alloys, that also appear liquid at room temperature.

Among them, mercury, also known as mercury, is the most common in daily life and can be used in fields such as thermometers, sphygmomanometers, and electrodes. However, mercury is extremely toxic and volatile, and can permanently damage the nervous system, immune system, and cardiovascular system. In severe cases, it can lead to death. There is no need to discuss toxicity for other liquid metals, including sodium potassium alloys, rubidium, cesium, and francium. Because these elements are extremely lively and easily react violently with air, water, and even ice, causing explosions, they can only be used in special occasions. Gallium (Ga) is the only liquid metal that combines safety and comprehensive performance. Its melting point is only 29.76 ℃, and it is a solid at room temperature, but it will melt when held in hand. Liquid gallium can flow like water. Its biggest feature is its excellent thermal conductivity, which can replace condensate and thermal oil, and is expected to be applied in thermal control systems in high-performance computers, power semiconductors, and other scenarios.

In addition, as a “metal” and “liquid”, gallium can also flow directionally like water in electric fields, magnetic fields, gravity fields, and temperature fields. Therefore, it is expected to be applied in 3D printing and integrated circuit manufacturing. Of course, with the development of technology, humans may also create liquid robots like Terminator in the future. However, overall, research on low melting point metals is still at the forefront, and some scenarios are still in the realm of imagination, speculation, and even fantasy, with a considerable distance from practical applications.

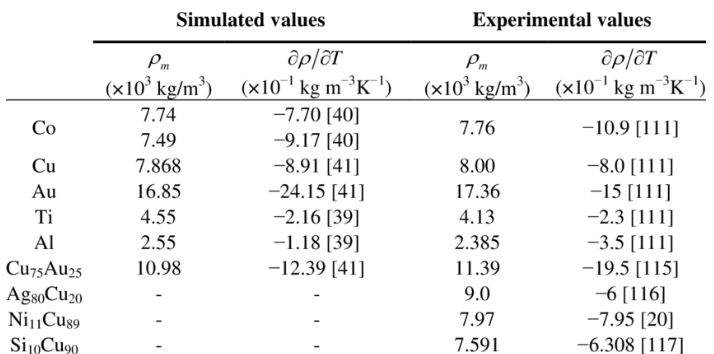

Densities of Liquid Metals

Advantages of Liquid Metals

Liquid metal is one of the few high profit products in the metal industry, which may gradually replace existing materials in the future and produce breakthrough products that can be widely used in consumer electronics, lithium batteries, 3D printing, flexible intelligent machines, vascular robots, and other fields.

The strength of liquid metal is more than 10 times that of magnesium aluminum alloy, and more than 2 times that of stainless steel and titanium alloy; The hardness is also more than 10 times that of magnesium aluminum alloy, and more than 1.5 times that of stainless steel and titanium alloy. And the density is moderate, lighter than stainless steel and slightly heavier than titanium alloy. These characteristics determine that liquid metal becomes the third generation new material for 3C products after engineering plastics and light alloys. A new round of technological revolution and industrial transformation is poised to emerge, with one breakthrough being new materials. Liquid metal, as one of the super materials that will dominate future high-tech competition, is expected to give birth to a trillion dollar blue ocean.

At present, there are three main directions for the reserve of liquid metal technology. The first is the strip, which is already quite mature; The second one is bulk amorphous; Another one is to make powder. Powder has two uses, one is for surface coating, which has functions such as wear resistance and corrosion resistance, and the other is for 3D printing.

Compared to powder metallurgy, liquid metal has a shrinkage rate of approximately 22% to 24% in powder metallurgy, and both horizontal and vertical shrinkage are different. The shrinkage rate of liquid metal is somewhat different, around 2.5 to 3.5 per thousand, which is very controllable, so the repeatability of liquid metal is very good.

Applications of Liquid Metals

The current application cases of liquid metal include bearings, hinges, SIM card holders/SIM card needles, fixtures, golf club heads, clock structural components, etc. However, due to the limited number of global suppliers, large-scale applications have not yet been formed. After the consumption of electronics, liquid metals will make continuous efforts in fields such as military, industrial, robotics, medical, environmental protection, and aviation, with unlimited prospects.

Liquid metal has been used in high-end watch brands such as Swatch and Omega since 2009 due to its superior material properties. The numbers and scales inside the watch are made of liquid metal, and its amorphous structure allows it to perfectly adhere to the ceramic bezel without creating any gaps. Zirconium Zr is an important component element of liquid metal alloys and also an important element in zirconia dioxide (ZrO2) ceramic materials. Due to the excellent hardness of the two materials, the bezel is perfectly smooth and can resist wear and corrosion.

In the field of consumer electronics, liquid metal was first known to Apple as a SIM card reader due to its high hardness, corrosion resistance, and wear resistance, which far exceed ordinary metals. Some companies have already used SIM card trays and spindles made of liquid metal materials for some terminals. With the maturity of liquid metal bulk forming technology, liquid metal is expected to be widely applied in intelligent terminal protection frames and internal structural components, and the era of liquid metal is about to emerge.

In addition to consumer electronics, future technologies such as bulk forming and increasing the non crystallinity ratio of liquid metals will be further improved. As a new material, the application range of liquid metals is exceptionally broad. In theory, any complex structural component in fields such as strength, hardness, wear and radiation resistance, insulation, and high elasticity can be replaced by liquid metal. Therefore, industries such as military, industrial, robotics, medical, environmental protection, and aviation will find a large number of application scenarios for liquid metal.

Researchers at the Massachusetts Institute of Technology in the United States have found that liquid metal technology can allow damaged metals to undergo extensive self repair. The ability to heal damaged nerve tissue has also begun to receive attention. Studies have shown that metals can maintain normal temperature in the human body, and liquid metals can be used in medical surgeries. This innovative technology may be used in the future to repair human nerve tissue and benefit patients.