The ejection system is an important mechanism in molding, and a specific ejection method will be used in manufacturing. Today let’s get a basic understanding of the mold ejector and ejection system.

What Is a Mold Ejector?

A mold ejector is a mechanism used in injection molding machines to remove a plastic part or product from a mold cavity. The ejector system consists of pins or blades that push the part out of the mold after it has been formed and cooled.

When the injection molding process is complete, the mold is opened and the ejector pins or blades are activated to push the finished part out of the mold. The number and location of the ejector pins depend on the shape and size of the molded part, as well as the design of the mold.

Mold ejectors are an important component of the injection molding process, as they ensure that the finished parts are released from the mold cleanly and without damage. Without a proper ejector system, it would be difficult to extract the finished parts from the mold and the quality of the finished product would suffer.

What Is an Ejection System in Molding?

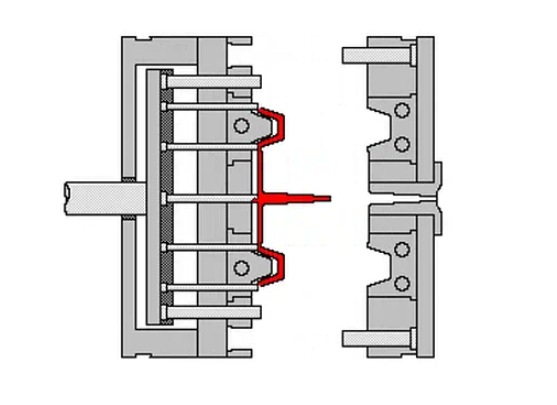

The ejection system in molding refers to the mechanism used to remove a finished plastic part from the mold cavity. In injection molding, the ejection system consists of ejector pins, which are located on the ejector plate and are used to push the part out of the mold cavity once it has been formed and cooled.

The ejector system is typically activated after the mold has been opened, either manually or through the use of a hydraulic or pneumatic system. The ejector pins are then driven into the mold, pushing the part out of the cavity and into a collection bin or conveyor belt for further processing.

The number and location of the ejector pins depend on the shape and size of the part being produced, as well as the design of the mold. The size and shape of the pins themselves can also vary, depending on the specific requirements of the molding process.

The ejection system is an important component of the injection molding process, as it helps ensure that the finished parts are released from the mold cleanly and without damage. A properly designed and implemented ejection system can help improve the efficiency and quality of the molding process while minimizing waste and reducing the risk of defects or damage to the finished product.

What Are the Different Types of Ejection?

In injection molding, there are several different types of ejection methods that can be used to remove a finished part from the mold cavity. Some of the most common types of ejection include:

– Pin Ejection: In this method, ejector pins are used to push the part out of the mold cavity. These pins are typically located on the ejector plate and are driven forward into the mold to eject the part.

– Blade Ejection: This method uses thin, flat blades to eject the part from the mold cavity. These blades are typically inserted into the mold and then rotated or moved in a specific direction to push the part out.

– Stripper Plate Ejection: With this method, a stripper plate is used to push the part out of the mold cavity. The stripper plate is located on the back side of the mold and is typically attached to the ejector plate.

– Air Ejection: This method uses compressed air to blow the part out of the mold cavity. It is often used for delicate or complex parts that cannot be easily ejected with other methods.

– Hydraulic Ejection: In this method, hydraulic cylinders are used to push the part out of the mold cavity. It is typically used for large or heavy parts that require a significant amount of force to eject.

How Is Ejection Done in Molding?

In molding, the ejection process typically follows these steps:

– Mold Opening: The molding machine opens the mold to reveal the finished part.

– Ejector Plate Movement: The ejector plate, which contains the ejector pins, moves forward and engages with the part.

– Ejector Pin Movement: The ejector pins, which are located on the ejector plate, move forward and push against the back of the part.

– Part Release: The part is released from the mold and moves out of the cavity.

– Ejector Pin Retraction: The ejector pins move back to their original position.

– Mold Closing: The molding machine closes the mold in preparation for the next molding cycle.

The ejection process is usually automated and controlled by the molding machine. The number and location of the ejector pins depend on the size and shape of the part, as well as the design of the mold. properly functioning ejection system is critical to the efficiency and quality of the molding process.