Wedge lock washers, often called Nord Lock washers, are engineered fastener components designed to maintain bolt tension and prevent loosening, even under intense vibration and dynamic loads. These washers have found their place in high-demand industries worldwide due to their unique locking principle, reliability, and ease of use. So what is a Nord Lock Washer exactly? This wedge locking washer explained guide will walk you through their definition, working principle, application, dimensions, installation, and more.

1. What is a Wedge Lock Washer (Nord-Lock Washer)?

Wedge lock washers are specialized fastener components designed to secure bolted joints by using tension rather than friction. Each assembly consists of a pair of washers with cams on one side and radial teeth on the other. The cam sides are joined together, usually with a mild adhesive, and are installed between the bolt head (or nut) and the joint material. This unique double-washer construction was developed by Sweden’s NORD-LOCK AB first and is widely recognized for its anti-loosening properties, so that’s why wedge lock washer is also known as the Nord-Lock Washer in the global market.

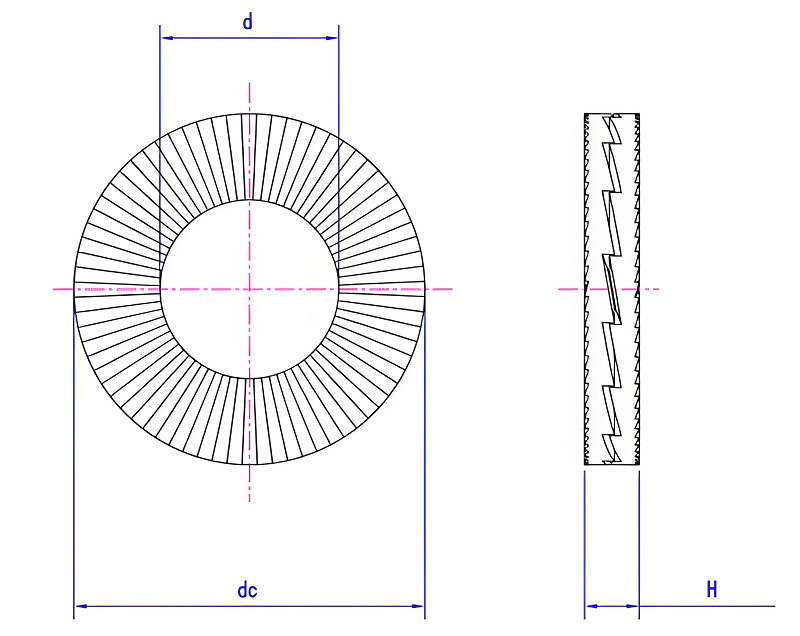

Wedge Lock Washer Design Diagram

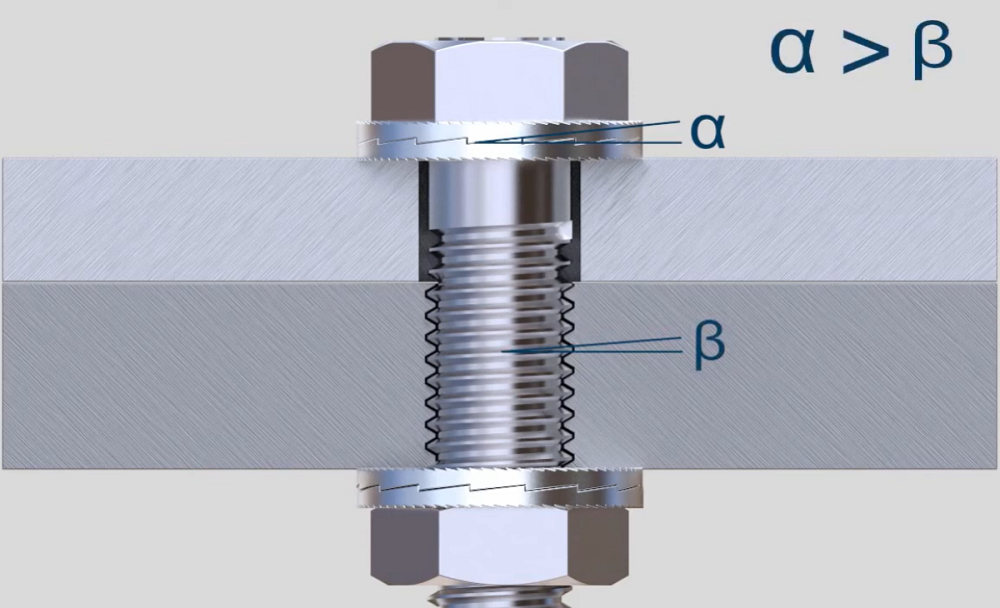

2. Nord Lock Washer Working Principle – How Wedge Lock Washers Work

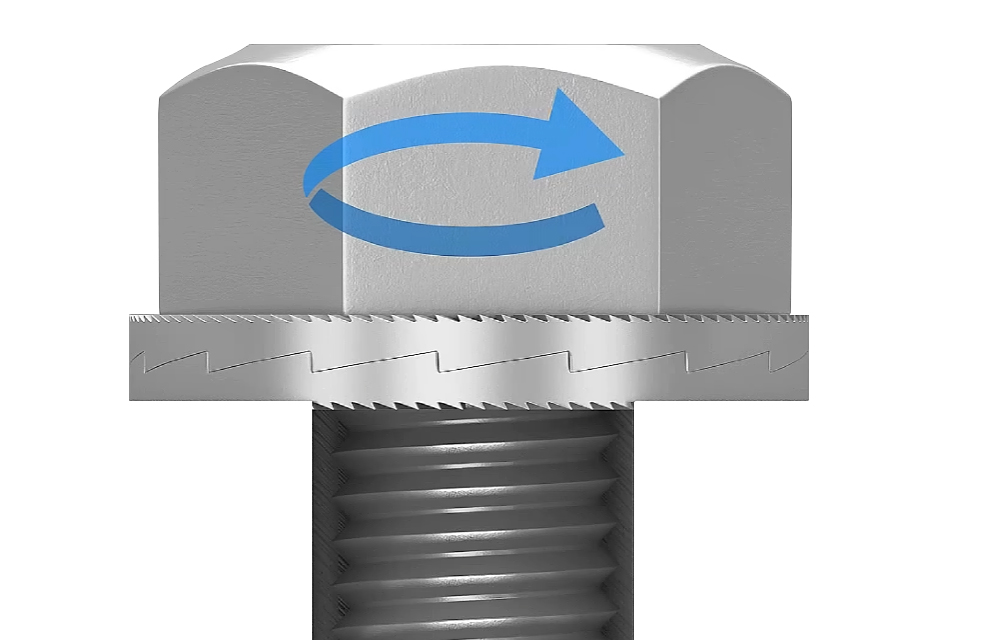

The wedge lock washer operates on a geometric principle. The cam angle (α) of the washers is engineered to be greater than the thread pitch angle (β) of the bolt. When the joint is subjected to vibration or dynamic loads, any tendency for the bolt or nut to rotate is counteracted by the wedge effect created between the cam surfaces. As loosening is attempted, the cams move up against each other, increasing the clamping force instead of reducing it. This prevents the fastener from coming loose unintentionally, maintaining the preload even in severe vibration or load conditions.

When untightening, the top washer’s cam rides over the bottom washer’s cam, which stretches the bolt further before it can be loosened. This mechanism leaves clear impression marks from the washer serrations on the mating material, indicating the security provided by the wedge-locking action.

3. Nord Lock Washer Function – How/When Should You Use a Wedge Lock Washer?

Wedge locking washers are best used in scenarios where bolts are exposed to vibrations, dynamic loads, or high temperatures. Their unique locking mechanism ensures that bolted joints remain tight and reliable over time. These washers are particularly suited for:

- Equipment subject to frequent vibrations.

- Applications requiring consistent preload in bolted joints.

- Situations where traditional locking mechanisms, like spring washers or nylon nuts, fail to maintain performance.

4. Nord Lock Washer Applications – Where To Use Wedge Lock Washer?

Wedge locking washers are widely used across various industries, especially where vibration, shock, and safety are major concerns. Key applications include:

- Automotive: Used in wheel nuts, drive shafts, engine mounts, and transmission housings to prevent loosening.

- Diesel Engines: Secures turbochargers, exhaust manifolds, and fuel ducts, withstanding high temperatures and strong vibrations.

- Heavy-Duty Trucks & Construction Machinery: Simplifies assembly and prevents stud bolts from loosening under vibration.

- Railways and Urban Rail Transit: Maintains joint integrity in railways, maglev trains, and large infrastructure projects.

- Wind Turbines, Shipbuilding, Oil & Gas, Mining: Ensures safety in bolted joints for critical equipment.

- Aerospace, Military, Power Generation: Provides reliable fastening in aircraft, military vehicles, and power systems.

- Public Utilities, Bridges, Agricultural Machinery, Foundry Equipment, Jack Hammers, and More.

These washers are widely recognized for their performance in projects such as the Qinghai-Tibet Railway, the East China Sea Bridge, and the Hangzhou Bay Bridge.

5. Wedge Lock Washer Dimensions (Sizes, Thickness, Weight)

Wedge lock washers are available in a broad range of sizes to match most metric and inch fasteners. For example, Nord Lock washers are manufactured from M3 to M130 (metric) and corresponding inch sizes as required. Each nord-lock washer size has specific inner and outer diameters and thicknesses, ensuring compatibility with standard bolt sizes. For instance, an NL10 washer (for M10 bolts) typically has an inner diameter of 10.7 mm, an outer diameter of 16.6 mm, and a thickness of 2.5 mm. Weight per 100 pairs varies depending on the dimensions, with detailed charts available from manufacturers.

Key Dimensions:

- Inner Diameter (d): The diameter of the hole through which the bolt passes.

- Outer Diameter (D): The overall diameter of the washer. Sometimes, there are “standard” and “large” (SP) outer diameters.

- Thickness (T): The thickness of the washer.

Standards & Sizes:

- Metric: Wedge lock washers are commonly available in metric sizes from M3 to M39, and even up to M130

- Imperial (Inch): Available, but selection may be more limited.

- DIN 25201: This is a common standard for wedge lock washers, particularly in Europe and Asia.

- Nord-Lock: A leading manufacturer. Their washers often meet or exceed industry standards

Metric Wedge Lock Washer Size Chart

| Nord-Lock Code | Size (Metric) | d (mm) | D (mm) | T (mm) |

|---|---|---|---|---|

| NL3 | M3 | 3.4 | 7 | 1.8 |

| NL3.5 | M3.5 | 3.9 | 7.6 | 1.8 |

| NL3.5sp | M3.5 | 3.9 | 9 | 1.8 |

| NL4 | M4 | 4.4 | 7.6 | 1.8 |

| NL4sp | M4 | 4.4 | 9 | 1.8 |

| NL5 | M5 | 5.4 | 9 | 1.8 |

| NL5sp | M5 | 5.4 | 10.8 | 1.8 |

| NL6 | M6 | 6.5 | 10.8 | 1.8 |

| NL6sp | M6 | 6.5 | 13.5 | 2.5 |

| NL8 | M8 | 8.7 | 13.5 | 2.5 |

| NL8sp | M8 | 8.7 | 16.6 | 2.5 |

| NL10 | M10 | 10.7 | 16.6 | 2.5 |

| NL10sp | M10 | 10.7 | 21 | 2.5 |

| NL11 | M11 | 11.4 | 18.5 | 2.5 |

| NL12 | M12 | 13 | 19.5 | 2.5 |

| NL12sp | M12 | 13 | 25.4 | 3.4 |

| NL14 | M14 | 15.2 | 23 | 3.4 |

| NL14sp | M14 | 15.2 | 30.7 | 3.4 |

| NL16 | M16 | 17 | 25.4 | 3.4 |

| NL16sp | M16 | 17 | 30.7 | 3.4 |

| NL18 | M18 | 19.5 | 29 | 3.4 |

| NL18sp | M18 | 19.5 | 34.5 | 3.4 |

| NL20 | M20 | 21.4 | 30.7 | 3.4 |

| NL20sp | M20 | 21.4 | 39 | 3.4 |

| NL22 | M22 | 23.4 | 34.5 | 3.4 |

| NL22sp | M22 | 23.4 | 42 | 4.6 |

| NL24 | M24 | 25.3 | 39 | 3.4 |

| NL24sp | M24 | 25.3 | 48.5 | 4.6 |

| NL27 | M27 | 28.4 | 42 | 5.8 |

| NL27sp | M27 | 28.4 | 48.5 | 5.8 |

| NL30 | M30 | 31.4 | 47 | 5.8 |

| NL30sp | M30 | 31.4 | 58.5 | 6.6 |

| NL33 | M33 | 34.4 | 48.5 | 5.8 |

| NL33sp | M33 | 34.4 | 58.5 | 6.6 |

| NL36 | M36 | 37.4 | 55 | 5.8 |

| NL36sp | M36 | 37.4 | 63 | 6.6 |

| NL39 | M39 | 40.4 | 58.5 | 5.8 |

| NL42 | M42 | 43.2 | 63 | 5.8 |

| NL45 | M45 | 46.2 | 70 | 7 |

| NL48 | M48 | 49.6 | 75 | 7 |

| NL52 | M52 | 53.6 | 80 | 7 |

| NL56 | M56 | 59.1 | 85 | 7 |

| NL60 | M60 | 63.1 | 90 | 7 |

| NL64 | M64 | 67.1 | 95 | 7 |

| NL68 | M68 | 71.1 | 100 | 9.5 |

| NL72 | M72 | 75.1 | 105 | 9.5 |

| NL76 | M76 | 79.1 | 110 | 9.5 |

| NL80 | M80 | 83.1 | 115 | 9.5 |

| NL85 | M85 | 88.1 | 120 | 9.5 |

| NL90 | M90 | 92.4 | 130 | 9.5 |

| NL95 | M95 | 97.4 | 135 | 9.5 |

| NL100 | M100 | 103.4 | 145 | 9.5 |

| NL105 | M105 | 108.4 | 150 | 9.5 |

| NL110 | M110 | 113.4 | 155 | 9.5 |

| NL115 | M115 | 118.4 | 165 | 9.5 |

| NL120 | M120 | 123.4 | 170 | 9.5 |

| NL125 | M125 | 128.4 | 173 | 9.5 |

| NL130 | M130 | 133.4 | 178 | 9.5 |

Wedge Lock Washer Size Chart in Inches

| Nord-Lock Code | Size (Inches) | d (mm) | D (mm) | T (mm) |

|---|---|---|---|---|

| NL1/4″ | 1/4″ | 7.2 | 11.5 | 2.5 |

| NL1/4″sp | 1/4″ (special) | 7.2 | 13.5 | 2.5 |

| NL3/8″ | 3/8″ | 10.3 | 16.6 | 2.5 |

| NL3/8″sp | 3/8″ (special) | 10.3 | 21 | 2.5 |

| NL1/2″ | 1/2″ | 13.5 | 19.5 | 2.5 |

| NL1/2″sp | 1/2″ (special) | 13.5 | 25.4 | 3.4 |

| NL3/4″ | 3/4″ | 20 | 30.7 | 3.4 |

| NL3/4″sp | 3/4″ (special) | 20 | 39 | 3.4 |

| NL1″ | 1″ | 27.9 | 39 | 3.4 |

| NL1″sp | 1″ (special) | 27.9 | 48.5 | 4.6 |

| M3 | #5 | 3.4 | 7.0 | 1.7 |

| M3.5 | #6 | 3.9 | 7.6 | 1.7 |

| M4 | #8 | 4.4 | 7.6 | 1.7 |

| M5 | #10 | 5.4 | 9.0 | 1.7 |

| M8 | 5/16″ | 8.6 | 13.5 | 2.7 |

| M11 | 7/16″ | 11.4 | 18.5 | 2.7 |

| M14 | 9/16″ | 15.2 | 23.0 | 3.7 |

| M16 | 5/8″ | 17.0 | 25.4 | 3.7 |

| M18 | 3/4″ | 20.0 | 30.7 | 3.7 |

| M20 | 7/8″ | 23.4 | 34.5 | 3.7 |

| M30 | 1 1/8″ | 31.4 | 47.0 | 5.7 |

| M33 | 1 1/4″ | 34.4 | 48.5 | 5.5 |

| M36 | 1 3/8″ | 37.4 | 55.0 | 6.5 |

| M39 | 1 1/2″ | 40.4 | 58.5 | 6.2 |

6. Wedge Lock Washer Torque Values

The installation torque for wedge locking washers depends on factors such as lubrication, bolt coating, and bolt grade. For example, the reference torque for a carbon steel washer with a grade 10.9 coated bolt should be determined according to relevant standards and adjusted for thread and washer friction coefficients. It is recommended to refer to standards for precise torque values. Lubrication on the threads is acceptable, but avoid lubricating the washer’s serrated faces, as they must bite into the mating surfaces to function properly. The breakaway torque is typically similar to a standard joint, but the time and energy required to actually loosen the fastener is increased due to the wedge effect.

Wedge Lock Washer Torque Chart

Reference values for carbon steel washers with grade 10.9 coated bolts:

| Washer Size | Bolt Size | Thread Pitch (mm) | Oil Lubricated<br>Torque (Nm) | Oil Lubricated<br>Axial Force (kN) | Cu/Graphite Paste<br>Torque (Nm) | Cu/Graphite Paste<br>Axial Force (kN) |

|---|---|---|---|---|---|---|

| NL3 | M3 | 0.5 | 1.8 | 3.2 | 1.8 | 3.4 |

| NL4 | M4 | 0.7 | 4.1 | 5.6 | 4.6 | 5.7 |

| NL5 | M5 | 0.8 | 8.6 | 8.6 | 9.7 | 8.8 |

| NL6 | M6 | 1.0 | 14 | 12 | 15 | 13 |

| NL8 | M8 | 1.25 | 34 | 21 | 36 | 22 |

| NL10 | M10 | 1.5 | 67 | 37 | 73 | 39 |

| NL12 | M12 | 1.75 | 115 | 53 | 127 | 54 |

| NL14 | M14 | 2.0 | 183 | 84 | 203 | 86 |

| NL16 | M16 | 2.0 | 285 | 108 | 318 | 111 |

| NL18 | M18 | 2.5 | 396 | 148 | 445 | 152 |

| NL20 | M20 | 2.5 | 545 | 185 | 613 | 190 |

| NL22 | M22 | 2.5 | 745 | 236 | 839 | 243 |

| NL24 | M24 | 3.0 | 970 | 289 | 1092 | 298 |

| NL27 | M27 | 3.0 | 1360 | 389 | 1532 | 401 |

| NL30 | M30 | 3.5 | 1860 | 509 | 2094 | 525 |

| NL33 | M33 | 3.5 | 2526 | 681 | 2840 | 703 |

| NL36 | M36 | 4.0 | 3250 | 876 | 3646 | 904 |

| NL39 | M39 | 4.0 | 4205 | 1138 | 4723 | 1175 |

| NL42 | M42 | 4.5 | 5202 | 1376 | 4743 | 659 |

Notes:

- Oil Lubricated: GF=71%, μth=0.13, μk=0.14

- Cu/Graphite Paste Lubricated: GF=75%, μth=0.11, μk=0.15

- GF is yield ratio; μth is thread friction coefficient; μk is washer friction coefficient

- For more precise installation torque, refer to FST-10 standard.

7. Wedge Lock Washer Standards

Wedge lock washers are primarily governed by the following standards, though regional variations and specific manufacturer specifications may also apply:

- DIN 25201 (Deutsches Institut für Normung – German Institute for Standardization) – This is a commonly cited standard for wedge lock washers, particularly in Europe and Asia. DIN 25201 specifies dimensions, materials (typically spring steel), and performance requirements for wedge lock washers. It often involves hardened spring steel and a flake zinc-plated surface, and covers a range of metric sizes, typically from M3 to M100 or M130.

- EN 14399-3/EN 14399-4/EN 14399-8 (European Standard) – These standards are relevant for steel construction applications, particularly for HV/HR sets bolts and nuts. Nord-Lock SC-washers are designed to fit these standards and can replace plain washers according to EN 14399-6.

- Nord-Lock Specifications – Nord-Lock is a leading manufacturer of wedge lock washers, and their products often meet or exceed industry standards. They offer washers in various materials (steel, stainless steel, SMO 254, Alloy 718, Alloy C-276) and sizes. Nord-Lock washers are designed to utilize tension instead of friction for secure bolted joints. They also offer SP washers with enlarged outer diameters for use with flanged bolts/nuts or on soft materials.

- ISO Standards – While a specific ISO standard number isn’t consistently mentioned for wedge lock washers, some manufacturers may adhere to ISO 9001 or ISO TS16949 for quality management. Nord-Lock SP washers are designed for flanged bolts and nuts (ISO 4161, 4162).

- ASTM Standards – It’s important to note that, generally, there isn’t a direct ASTM standard for wedge lock washers. ASTM F436 covers hardened steel washers, but not specifically wedge lock washers.

| Standard/Spec | Region/Use | Key Features |

|---|---|---|

| DIN 25201 | Global | Metric sizes, materials, hardness, performance |

| EN 14399-3/4/8/6 | Europe | Steel construction, HV/HR sets, washer compatibility |

| Manufacturer Specs | Global | Wider material range, SP washers, product-specific details |

| ISO 9001, IATF 16949 | Global | Quality management systems |

| ASTM F436 | North America | General hardened washers (not wedge lock) |

| DIN 65151 | Global | Junker vibration testing |

8. Wedge Lock Washer Prices

The price of wedge lock washers is generally higher than that of basic spring or tooth lock washers due to their advanced design and manufacturing precision. Cost varies depending on the material (stainless steel, carbon steel, alloy steel), size, quantity, and surface treatment. However, their durability, reusability, and ability to prevent downtime or safety incidents make them a cost-effective choice for demanding applications.

9. Wedge Lock Washer Installation

To install, position the pair of wedge locking washers so the cam sides face each other, and the serrated sides contact the bolt head/nut and the joint material. Tighten the bolt or nut to the specified torque value. For first-time use, the washers are supplied glued together for convenience. For reuse, inspect for any tooth damage or cracks and reassemble the washers correctly. Do not use wedge lock washers in combination with other types of washers unless specified, and avoid installations on surfaces that cannot support the serrations or in precision assemblies where surface marking is not allowed.

How To Put On a Wedge Locking Washer (Nord-Lock Washer):

- Place the washer pair between the bolt head or nut and the joint surface, ensuring that the cams face each other.

- Tighten the bolt to the recommended torque value.

- Avoid using additional flat washers, as they may interfere with the locking mechanism.

- Ensure the mating surface is clean and free of debris to maximize the washer’s performance.

Reusability is possible, but the washers should be inspected for damage before reuse.

10. Wedge Lock Washer Equivalent

Wedge lock washers offer a unique tension-based locking effect that standard spring or tooth lock washers cannot match. In cases where wedge lock washers are not suitable, alternative solutions include:

- Spring Washers: Provide basic anti-loosening properties.

- Double Nuts: A traditional method for securing bolts.

- Chemical Thread Lockers: Adhesive-based locking solutions.

However, these alternatives may not offer the same level of reliability in high-vibration or high-temperature environments as wedge lock washers.