A tap drill is one of the most important tools in any machine shop or metalworking environment. It’s used to create the correct-sized hole that will later be threaded by a tap, ensuring precise and durable internal threads for screws, bolts, or fasteners. In simple terms, the tap drill determines the foundation of the threading process—get the hole size wrong, and the threads won’t fit properly or may fail under stress. This guide explains what a tap drill size chart and calculator is.

What is a Tap Drill?

Drill/taps are versatile cutting tools that combine the functions of drilling and tapping into a single tool. These tools are designed to drill a hole and then create threads in one continuous operation, improving efficiency and reducing the need for tool changes.

Advantages of Using a Tapping Drill

- Ensures Accurate Thread Formation

A tap drill creates the exact hole diameter needed so that when the tap cuts threads, they have the correct depth and profile. Without a properly sized tap drill, threads may be too shallow (if the hole is too big) or the tap may break (if the hole is too small). - Reduces Tap Breakage and Tool Wear

By removing the right amount of material before tapping, a tap drill minimizes stress on the tap itself. This lowers the risk of tool breakage, especially when working with hard metals or deep holes. - Improves Thread Strength and Consistency

When the tap drill is properly sized, the resulting threads have uniform engagement along their length. This ensures maximum holding strength and better fit with fasteners. - Enhances Surface Finish of Threads

The tap cuts more smoothly when the hole is pre-drilled correctly, resulting in cleaner, more precise threads that require little or no post-processing. - Increases Machining Efficiency

A correctly chosen tap drill reduces cutting torque and vibration during tapping, which leads to faster machining speeds and improved productivity. - Supports Wide Range of Thread Types

Tap drills can be used for different thread standards (metric, UNC, UNF, BSP, etc.), making them highly adaptable in manufacturing, maintenance, and repair operations. - Reduces Scrap and Material Waste

Proper hole sizing minimizes the risk of thread defects, which means fewer rejected parts and lower production costs.

Tap Drill Chart

Standard 75% Thread Depth

| Screw/Bolt Size | Thread Type | Tap Drill Size | Closest Fractional | Decimal (in) |

|---|---|---|---|---|

| 0-80 | NF | 3/64″ | 3/64″ | .0469 |

| 1-64 | NC | #53 | — | .0595 |

| 1-72 | NF | #53 | 1/16″ | .0595 |

| 2-56 | NC | #50 | — | .0700 |

| 2-64 | NF | #50 | — | .0700 |

| 3-48 | NC | #47 | 5/64″ | .0785 |

| 3-56 | NF | #45 | — | .0820 |

| 4-36 | NS | #44 | — | .0860 |

| 4-40 | NC | #43 | 3/32″ | .0890 |

| 4-48 | NF | #42 | 3/32″ | .0935 |

| 5-40 | NC | #38 | — | .1015 |

| 5-44 | NF | #37 | — | .1040 |

| 6-32 | NC | #35 | 7/64″ | .1100 |

| 6-40 | NF | #33 | — | .1130 |

| 8-32 | NC | #29 | — | .1360 |

| 8-36 | NF | #29 | 9/64″ | .1360 |

| 10-24 | NC | #25 | 5/32″ | .1495 |

| 10-32 | NF | #21 | 5/32″ | .1590 |

| 12-24 | NC | #16 | 11/64″ | .1770 |

| 12-28 | NF | #14 | 3/16″ | .1820 |

| 1/4-20 | NC | #7 | 13/64″ | .2010 |

| 1/4-28 | NF | #3 | 7/32″ | .2130 |

| 5/16-18 | NC | Letter F | 17/64″ | .2570 |

| 5/16-24 | NF | Letter I | — | .2720 |

| 3/8-16 | NC | 5/16″ | 5/16″ | .3125 |

| 3/8-24 | NF | Letter Q | 21/64″ | .3320 |

| 7/16-14 | NC | Letter U | 23/64″ | .3680 |

| 7/16-20 | NF | 25/64″ | 25/64″ | .3906 |

| 1/2-13 | NC | 27/64″ | 27/64″ | .4219 |

| 1/2-20 | NF | 29/64″ | 29/64″ | .4531 |

| 9/16-12 | NC | 31/64″ | 31/64″ | .4844 |

| 9/16-18 | NF | 33/64″ | 33/64″ | .5156 |

| 5/8-11 | NC | 17/32″ | 17/32″ | .5312 |

| 5/8-18 | NF | 37/64″ | 37/64″ | .5781 |

| 3/4-10 | NC | 21/32″ | 21/32″ | .6562 |

| 3/4-16 | NF | 11/16″ | 11/16″ | .6875 |

| 7/8-9 | NC | 49/64″ | 49/64″ | .7656 |

| 7/8-14 | NF | 13/16″ | 13/16″ | .8125 |

| 1-8 | NC | 7/8″ | 7/8″ | .8750 |

| 1-14 | NF | 15/16″ | 15/16″ | .9375 |

| 1 1/4-7 | NC | 1 7/64″ | 1 7/64″ | 1.1094 |

| 1 1/4-12 | NF | 1 11/64″ | 1 11/64″ | 1.1719 |

Metric Tap Drill Chart

| Metric Size | Pitch | Tap Drill | Decimal (in) |

|---|---|---|---|

| M3 × 0.5 | 0.50 | 2.5 mm | .0984 |

| M4 × 0.7 | 0.70 | 3.3 mm | .1299 |

| M5 × 0.8 | 0.80 | 4.2 mm | .1654 |

| M6 × 1.0 | 1.00 | 5.0 mm | .1969 |

| M7 × 1.0 | 1.00 | 6.0 mm | .2362 |

| M8 × 1.25 | 1.25 | 6.8 mm | .2677 |

| M10 × 1.5 | 1.50 | 8.5 mm | .3346 |

| M12 × 1.75 | 1.75 | 10.2 mm | .4016 |

| M14 × 2.0 | 2.00 | 12.0 mm | .4724 |

| M16 × 2.0 | 2.00 | 14.0 mm | .5512 |

| M18 × 2.5 | 2.50 | 15.5 mm | .6102 |

| M20 × 2.5 | 2.50 | 17.5 mm | .6889 |

Tap & Drill Chart (UNC – Coarse Threads)

| Screw Size | TPI | Tap Drill (inch) | Tap Drill (mm) |

|---|---|---|---|

| #4-40 | 40 | 0.089″ (#43) | 2.26 mm |

| #6-32 | 32 | 0.1065″ (#36) | 2.70 mm |

| #8-32 | 32 | 0.136″ (#29) | 3.45 mm |

| #10-24 | 24 | 0.1495″ (#25) | 3.80 mm |

| 1/4″-20 | 20 | 0.201″ (#7) | 5.10 mm |

| 5/16″-18 | 18 | 0.257″ (F) | 6.53 mm |

| 3/8″-16 | 16 | 0.3125″ (5/16) | 7.94 mm |

| 1/2″-13 | 13 | 0.4219″ (27/64) | 10.72 mm |

Tap & Drill Chart (UNF – Fine Threads)

| Screw Size | TPI | Tap Drill (inch) | Tap Drill (mm) |

|---|---|---|---|

| #4-48 | 48 | 0.086″ (#44) | 2.18 mm |

| #6-40 | 40 | 0.0995″ (#40) | 2.52 mm |

| #8-36 | 36 | 0.1285″ (#30) | 3.26 mm |

| #10-32 | 32 | 0.159″ (#21) | 4.04 mm |

| 1/4″-28 | 28 | 0.213″ (3/16) | 4.83 mm |

| 5/16″-24 | 24 | 0.272″ (I) | 6.90 mm |

| 3/8″-24 | 24 | 0.332″ (Q) | 8.43 mm |

| 1/2″-20 | 20 | 0.453″ (29/64) | 11.51 mm |

Metric Tap & Drill Chart (Coarse Pitch)

| Thread Size | Pitch | Tap Drill (mm) |

|---|---|---|

| M3 | 0.5 | 2.5 mm |

| M4 | 0.7 | 3.3 mm |

| M5 | 0.8 | 4.2 mm |

| M6 | 1.0 | 5.0 mm |

| M8 | 1.25 | 6.8 mm |

| M10 | 1.5 | 8.5 mm |

| M12 | 1.75 | 10.2 mm |

| M14 | 2.0 | 12.0 mm |

| M16 | 2.0 | 14.0 mm |

Metric Tap & Drill Chart (Fine Pitch)

| Thread Size | Pitch | Tap Drill (mm) |

|---|---|---|

| M8 | 1.0 | 7.0 mm |

| M10 | 1.25 | 8.8 mm |

| M12 | 1.5 | 10.5 mm |

| M14 | 1.5 | 12.5 mm |

| M16 | 1.5 | 14.5 mm |

Tap Drill Size Calculator (For 75% Thread Depth)

For Metric Threads

Formula:

Example:

M10 × 1.5 →

10 − 1.5 = 8.5 mm tap drill

| Thread (Metric) | Pitch (mm) | Tap Drill (mm) |

|---|---|---|

| M3 × 0.5 | 0.5 | 2.5 |

| M4 × 0.7 | 0.7 | 3.3 |

| M5 × 0.8 | 0.8 | 4.2 |

| M6 × 1.0 | 1.0 | 5.0 |

| M8 × 1.25 | 1.25 | 6.8 |

| M10 × 1.5 | 1.5 | 8.5 |

| M12 × 1.75 | 1.75 | 10.2 |

| M14 × 2.0 | 2.0 | 12.0 |

| M16 × 2.0 | 2.0 | 14.0 |

| M20 × 2.5 | 2.5 | 17.5 |

For Imperial (UNC / UNF) Threads

Formula:

To achieve 75% thread depth, you subtract a slightly smaller amount (~0.013 × pitch).

Simplified rule of thumb for 75% thread engagement:

Example:

1/4-20 UNC

→ Pitch = 1 / 20 = 0.05

→ Tap Drill = 0.25 − (0.013 × 0.05) ≈ 0.201 in (#7 drill)

| Thread (Inch) | TPI | Tap Drill (inch) | Drill # |

|---|---|---|---|

| 4-40 UNC | 40 | .089 | #43 |

| 6-32 UNC | 32 | .106 | #36 |

| 8-32 UNC | 32 | .136 | #29 |

| 10-24 UNC | 24 | .149 | #25 |

| 10-32 UNF | 32 | .159 | #21 |

| 1/4-20 UNC | 20 | .201 | #7 |

| 5/16-18 UNC | 18 | .257 | Letter F |

| 3/8-16 UNC | 16 | .312 | 5/16″ |

| 1/2-13 UNC | 13 | .421 | 27/64″ |

Optional – Convert to Drill Letter/Number/Fraction

You can cross-check your tap drill result with this simple reference:

| Decimal (in) | Drill Size |

|---|---|

| .106 | #36 |

| .136 | #29 |

| .149 | #25 |

| .201 | #7 |

| .257 | F |

| .312 | 5/16″ |

| .421 | 27/64″ |

Tap Drill Size Formula

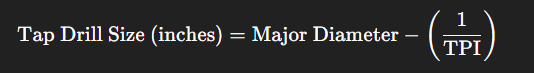

- Inch (UNC/UNF) Tap Drill Size Formula

For standard 60° threads:

Tap Drill (inch) = Major Diameter − (1 ÷ TPI)

Where:

Major Diameter = nominal screw size (e.g., 1/4″ = 0.250″)

TPI = threads per inch

Example — 1/4″-20 UNC

Major diameter = 0.250

TPI = 20

Tap drill = 0.250 − (1 ÷ 20)

Tap drill = 0.250 − 0.050

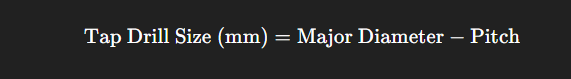

Tap drill = 0.200″ → drill #7 (0.201″) - Metric Tap Drill Size Formula

For standard ISO metric 60° threads:

Tap Drill (mm) = Major Diameter − Pitch

Where:

Major Diameter = M size (e.g., M10 = 10 mm)

Pitch = thread pitch in mm (e.g., 1.5, 1.25, 1.0)

Example — M10 × 1.5

Major diameter = 10 mm

Pitch = 1.5 mm

Tap drill = 10 − 1.5

Tap drill = 8.5 mm - Adjusted Formula for ~75% Thread Engagement

Machinists sometimes target ~70–75% thread (strong and easier to tap):

Tap Drill = Major Diameter − (0.9743 × Pitch)

(For UNC: Pitch = 1 ÷ TPI)

This is more precise but usually unnecessary unless doing precision machining. - Quick Memory Shortcut

Inch: Drill = Size − 1/TPI

Metric: Drill = Size − Pitch

Standard M8 Tap Drill Sizes

M8 × 1.25 (coarse pitch – most common)

Tap drill: 6.8 mm

M8 × 1.0 (fine pitch)

Tap drill: 7.0 mm

M8 × 0.75 (extra fine)

Tap drill: 7.3 mm

Quick Formula (Metric)

Tap Drill = Major Diameter − Pitch

So for M8 × 1.25:

8 − 1.25 = 6.75 mm → standardized to 6.8 mm

Standard M3 Tap Drill Sizes

M3 × 0.5 (coarse pitch – most common)

Tap drill: 2.5 mm

M3 × 0.35 (fine pitch)

Tap drill: 2.65 mm

Quick Formula (Metric)

Tap Drill = Major Diameter − Pitch

So for M3 × 0.5:

3 − 0.5 = 2.5 mm (matches the standard)