Square threads are an important profile used in screws, nuts, and bolts designed for power transmission. Their unique shape, high efficiency, and specific engineering characteristics make them suitable for applications where movement and force transmission are key requirements. In today’s blog, we are going to talk about square thread in detail, including definition, diagram, structure (profile, pitch, angle, etc.), applications, size chart, types, standards, dimension calculation, and how they compare to other thread forms such as ACME, trapezoidal, and V threads.

What is Square Thread?

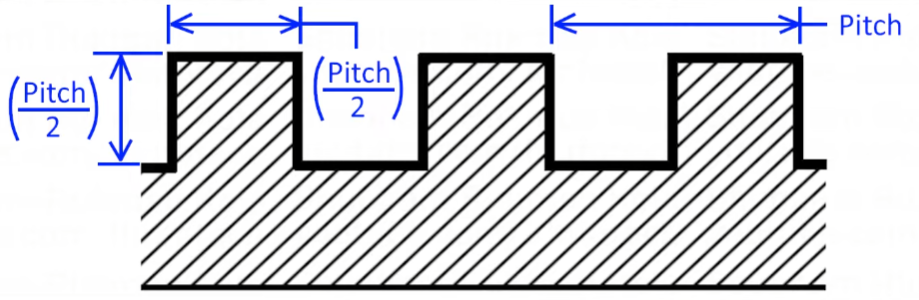

A square thread is a type of screw thread where the profile is essentially square in section. The flanks of the thread are perpendicular to the axis, and the square thread depth and width equal half pitch. The thread angle is zero, giving the thread its distinctive appearance and properties. Due to the nature of its guide surface, which is also square, this thread structure is widely found in mechanical and construction applications that require efficient power transmission.

Square Thread Drawing Diagram

Square Thread Profile

Square threads have a rectangular cross-section, with flanks perpendicular to the thread axis and a thread angle of zero degrees. The depth and thickness of the thread are each equal to half the pitch. The profile height is typically 0.5413 or 0.6133 times the nominal diameter, depending on the calculation method. The crest of the thread may also be chamfered to reduce burr formation.

Square Thread Angle

The thread angle of a square thread is 0° or 90° . This means the sides (flanks) of the thread are perfectly perpendicular to the axis of the screw. Unlike other thread types, such as V threads (which have a 60° angle), square threads have no included angle between the flanks. This design reduces friction and increases transmission efficiency, making square threads ideal for power transmission and linear motion applications. Some references describe the thread angle between one flank and the axis of the screw. Since each flank is perpendicular to the axis, this angle is 90°.

Square Thread Pitch

Pitch is defined as the distance between two adjacent threads measured parallel to the axis. For square threads, the standard pitch is generally 1.5 times the nominal diameter (P = 1.5d), meaning square thread depth equal to half pitch. For instance, an M10 square thread typically has a pitch of 15 mm.

Square Thread Starts

Square threads can be produced as single-start or multi-start. Single-start threads have one continuous thread, while multi-start threads have two or more threads running in parallel, which increases lead and allows for faster linear motion.

Square Thread Insert

A square thread insert is a mechanical component designed with an internal or external square thread profile, used to provide a durable and precise threaded interface within an assembly. Square thread inserts are typically installed into a softer or worn-out base material to restore or enhance its screw-threading capability, especially in high-load or power transmission applications.

Square Thread Applications – What are Square Threads Used For?

The primary purpose of square threads is efficient power transmission with minimal frictional losses. Their structure makes them ideal for converting rapid rotary motion into slow, controlled linear motion, this is commonly needed in mechanisms like lead screws in lathes, jacks, presses, and vices. The square form ensures that vertical flanks reduce friction and wear, making them suitable for applications where efficiency and smooth motion are more important than holding strength or resistance to unscrewing.

Square threads are not typically used for general fastening, but rather in systems where efficient movement and low friction are necessary for transmitting power or motion, so they are are widely used in applications involving the movement of large loads or requiring precise linear motion. Common uses include:

- Lead screws in lathes: They transform rotary motion of the screw into linear movement of the nut, which is crucial in machine tools for accurate positioning.

- Screw jacks: Used to lift heavy loads by translating rotary motion to linear force.

- Vices and clamps: Allow controlled tightening and loosening.

- Mechanical presses: Provide the means to apply high force in a linear direction.

- Cranes and pliers: Utilized in mechanisms that require smooth, efficient power transmission.

- Square thread rods, bolts, screws, and nuts in machinery, construction, and power tools for connecting or moving parts.

Square Thread Types & Uses

Square Threads are primarily categorized into several types based on the number of threads, tooth profile, and intended application:

1. Standard Square Thread

Structure: Contains only one helical thread winding around the screw, with a rectangular tooth profile and a relatively large pitch (typically ranging from 5–20 mm).

Features: Offers simple processing and high root strength, but has poor self-locking properties. Well-suited for low-speed, heavy-load uses such as jacks and presses.

2. Double-Start Square Thread

Structure: Features two helical threads that run parallel, effectively doubling the pitch compared to the single-start variant (for example, a single thread with a 10 mm pitch would have a double thread with a 20 mm pitch).

Features: Increases transmission efficiency and enables faster linear movement, but typically requires a locking mechanism. Common in mechanisms that need rapid advancement and retraction, like machine tool feed systems.

3. Trapezoidal Square Thread

Structure: The thread profile adopts an isosceles trapezoid, with flank angles commonly at 15° or 30°. Pitch range is broad (3–50 mm).

Features: Delivers both load-bearing capacity and wear resistance, making it suitable for high-precision, long-life transmission components such as micrometer screws and ball screws in CNC machines.

4. Modified Square Thread

Structure: Similar to ordinary square threads but with a reduced thread depth—less than half the pitch, and the depth is adjusted based on application needs.

Features: The crest is chamfered at both ends to 45° to prevent burr formation. These threads are designed for situations where rapid movement is necessary, making them practical for mechanisms that require quick linear motion and less chance of thread damage.

Application Scenarios and Selection Recommendations

For Heavy-Duty Machinery – Single-start square threads are preferred for their high root strength (shear strength can reach 400–600 MPa), making them suitable for supporting high static loads.

For High-Frequency Transmission Systems – Double-start or trapezoidal square threads are more suitable, as their multi-start arrangement reduces the load on individual teeth and extends service life. Modified square threads are also an option where quick linear movement is required.

For Corrosive Environments – Stainless steel or surface treatments are recommended. The shallower grooves of trapezoidal square threads make them easier to protect against corrosion.

Square Thread Standards

Worldwide, square threads are standardized in various engineering standards, including:

- ISO Standards (such as ISO 2901. ISO 2902 for metric trapezoidal and square threads)

- DIN Standards (such as DIN 103 for trapezoidal threads, often referenced for square threads)

- ANSI/ASME B1.1 (Unified Inch Screw Threads, with reference for square and ACME thread types)

Square Thread Dimensions & Calculation Formula

The deminons of a square thread is indicated by a thread designation, such as M10, which represents a square thread with a nominal diameter of 10 mm. In addition to the nominal diameter, square threads also include parameters such as pitch, pitch diameter, and top diameter. The size ranges and standards of these parameters vary slightly in different standards.

Square Thread Dimensions

Before discussing square thread sizes, it is important to clarify several fundamental parameters that describe and define square thread dimensions:

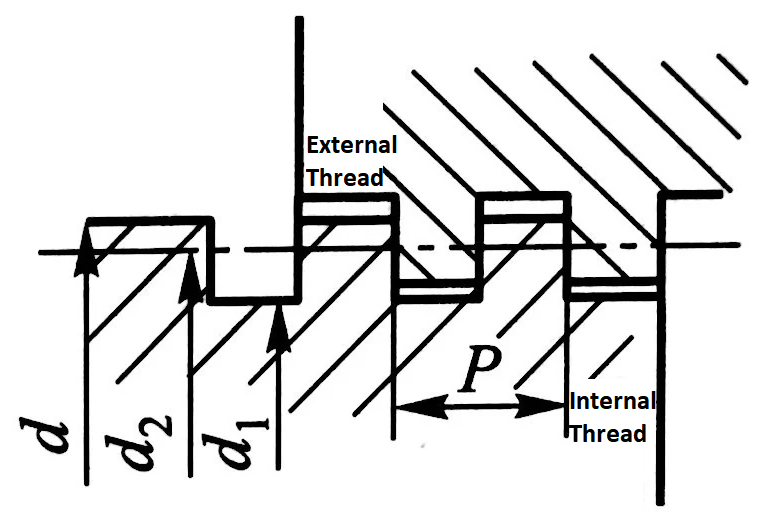

- d: Major Diameter (Outside Diameter) – The largest diameter of the external thread, measured from crest to crest. This is one of the main parameters for square threads, usually measured in millimeters (mm), and is used to distinguish different thread sizes.

- d₁: Minor Diameter (Root Diameter) – The smallest diameter of the external thread, measured at the base (root) of the threads. Also measured in millimeters (mm), this parameter is crucial for determining the strength of the thread.

- d₂: Pitch Diameter (Mean Diameter) – The diameter at which the width of the thread ridge and the width of the groove are equal. This is an important reference for thread fit and engagement.

- P: Pitch – The axial distance between two adjacent threads, measured in millimeters (mm). A smaller pitch results in finer threads, while a larger pitch results in coarser threads.

- h: Thread Height – The distance from the root to the crest of the thread, typically about half the pitch for square threads.

Square Thread Dimension Calculation

To calculate the various diameters for a square thread, the following formulas are used:

To calculate the various diameters for a square thread, the following formulas are used:

- Minor diameter: d₁ = d – 2h (where h is the thread depth, calculated as: h = 0.5𝑝)

- Pitch diameter: d₂ = d – 0.5p

- Pitch: 𝑝 = 1/4d₁

For example, for a thread with a nominal (major) diameter ddd and pitch ppp:

- The depth of the thread h = 0.5p

- The minor diameter d₁ = d−2h =d−p

- The pitch diameter d₂ = d−0.5p

Square Thread Efficiency and Self-Locking Calculation

The efficiency of a square thread screw can be determined by the following formula:

η = tan λ / tan (λ + ρ’)

where:

- λ is the lead angle of the screw

- ρ′ is the equivalent friction angle, which for square threads is calculated as tan−1f\tan^{-1} ftan−1f, with fff being the coefficient of friction (typically 0.10–0.15 for steel threads).

The self-locking condition for square threads is:

λ ≤ ρ’

This ensures that the screw will not rotate under load without an external torque.

Square Thread Dimension Tolerances

National standards specify dimensional tolerances for square threads, often categorized into grades such as 6h (general precision) and 4h (high precision). Higher precision results in smaller dimensional tolerances.

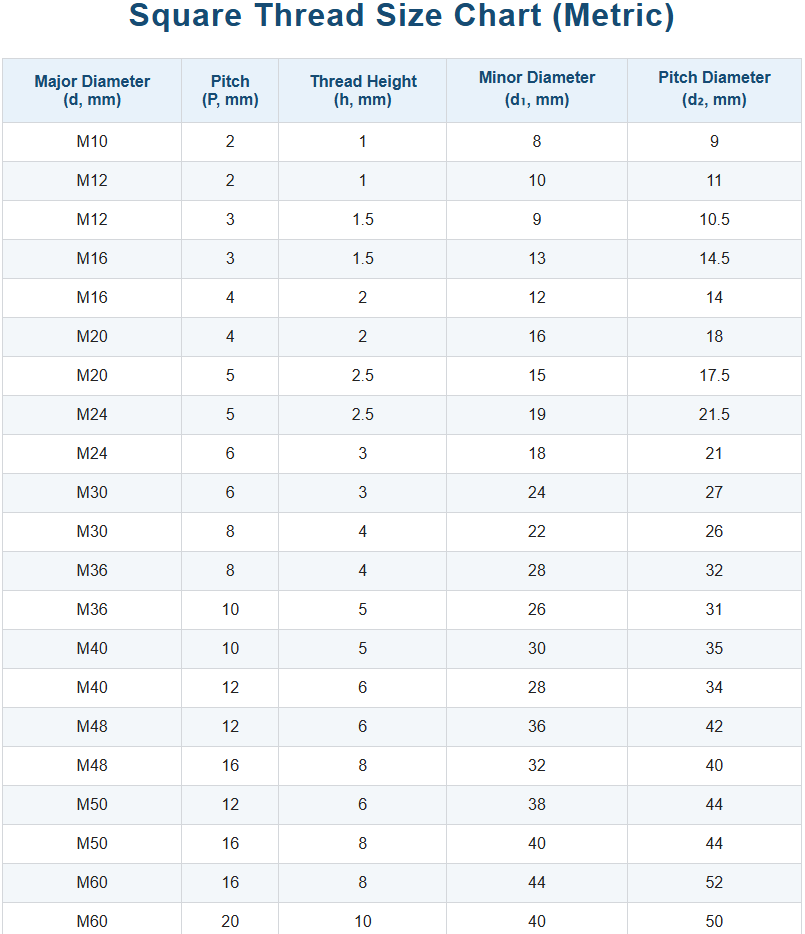

Standard Square Thread Size Chart (Metric)

Below is a metric square thread size chart, which lists the major diameter, pitch, thread height, minor diameter, and pitch diameter for various standard sizes:

How To Select Square Thread Sizes?

When choosing the appropriate square thread size for a specific application, several main factors should be considered:

- Load Requirements: For higher loads, select square threads with larger major diameters and pitches. A larger major diameter means greater load capacity. The strength and wear resistance of the thread are also important, especially for high-strength or heavy-duty use.

2. Structural Requirements: Based on installation space and mechanical structure, choose a suitable diameter and pitch. Smaller diameters may be needed for limited spaces, but this can affect thread strength and durability.

3. Transmission Requirements: For specific speed or adjustment needs, select a suitable pitch and thread height. A larger pitch allows for faster movement, while a smaller pitch provides finer adjustment.

4. Manufacturing Process: Different materials and processing methods may require different thread forms and sizes. Choose thread dimensions that are compatible with available equipment and processes.

How To Measure Square Thread Sizes?

Accurate measurement of square thread dimensions is essential for ensuring thread quality and proper fit:

Major Diameter (d): Use calipers or micrometers to measure the largest diameter across the thread crests.

Pitch (P): Use a thread pitch gauge to measure the distance between adjacent threads, or use calipers for direct measurement.

Thread Height (h): Measure the height from the root to the crest using a depth gauge, or calculate as (d – d₁) / 2.

Minor Diameter (d₁): Use calipers to measure the smallest diameter at the thread roots.

Pitch Diameter (d₂): The pitch diameter can be calculated or measured using specialized thread micrometers, or by averaging the major and minor diameters where applicable.

Square Thread Differences with Other Threads

Square Thread vs ACME Thread

Profile: Square threads have perpendicular flanks, while ACME threads have a 29-degree included angle.

Strength: ACME threads are stronger at the root due to their trapezoidal shape.

Manufacturing: ACME threads are easier to cut and allow for the use of split nuts.

Efficiency: Square threads have slightly higher efficiency because of their lower friction.

Square Thread vs V Thread

Profile: V threads have a 60-degree angle, square threads have zero-degree flank angles.

Strength: V threads are stronger due to greater thickness at the base.

Friction: Square threads have less friction and higher efficiency.

Use: V threads are suited for fastening, square threads for power transmission.

| Thread Type | Flank Angle | Strength at Root | Efficiency | Friction | Application | Manufacturing |

|---|---|---|---|---|---|---|

| Square | 0° | Lower | High | Low | Power Transmission | Harder |

| ACME (Trapezoidal) | 29° | Higher | Good | Moderate | Power Screws | Easier |

| V Thread | 60° | Higher | Lower | High | Fasteners | Easiest |