The location of the parting line is important in die casting and should be determined during the design and engineering phases. In this article, let’s discuss what is a parting line and how to identify it, as well as its importance and placement.

What is a Parting Line?

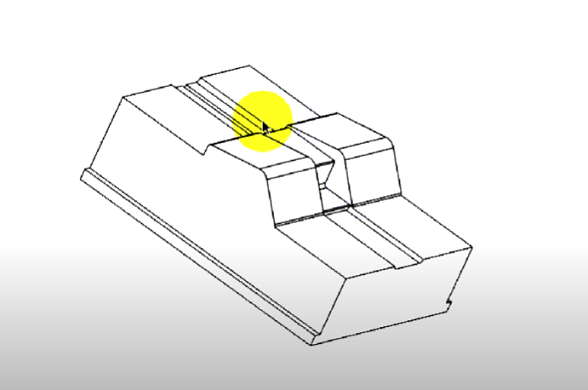

A parting line refers to the separation line or boundary between the two halves of a die or mold used in manufacturing processes like die casting, injection molding, or blow molding. It is the interface where the stationary half (also known as the cope) and the moving half (also known as the drag) of the die or mold come together. The molten material, such as metal or plastic, is injected or poured into the die or mold cavity through gating systems located around the parting line. Once the material solidifies and takes the desired shape, the die or mold halves are separated along the parting line, allowing the finished part to be removed. The parting line determines the shape and appearance of the final product.

How do you identify parting lines?

– Visual Inspection: Conduct a visual examination of the component or part to identify any visible seams or discontinuities. Parting lines often appear as straight or curved lines, sometimes with minor surface imperfections or marks where the two halves of the die or mold meet.

– CAD Models and Engineering Drawings: If you have access to computer-aided design (CAD) models or engineering drawings of the part, parting lines are typically represented as distinct edges or boundaries that indicate the separation between the two halves. These can be identified by examining the cross-sectional views, assembly drawings, or part geometry represented in the CAD model or engineering drawings.

– Molded or Cast Parts: In the case of existing molded or cast parts, the parting line is typically visible on the surface of the part. Inspect the part for any visible lines, features, or surface discontinuities that indicate where the two halves of the mold or die meet.

– Historical Knowledge or Documentation: If you have access to historical knowledge or documentation about the manufacturing process of the component, it may include information about the location of the parting line.

Why Is Parting Line Important in Die Casting?

1. The parting line is the boundary between the two halves of the die, it determines the shape and quality of the casting’s surface. A well-designed parting line ensures proper alignment and tightness of the die halves, preventing any leaks or flash formation during the casting process.

2. The parting line also affects the ejection of the casting from the die. After the molten metal solidifies and forms the desired shape, it needs to be expelled from the die. The position of the parting line determines where the ejection mechanism will be placed, ensuring smooth and efficient removal of the casting without causing any damage.

3. The parting line influences the positioning of the gating system, including the gates and runners through which molten metal flows into the die cavity. Proper gate and runner placement enables the molten metal to fill the cavity evenly and uniformly, minimizing defects such as porosity or insufficient fill.

4. Complex die castings may require the use of cores or sliders within the die to create internal features or undercuts. The parting line helps determine the location and orientation of these components for proper assembly and operation.

5. The parting line can affect post-casting operations such as machining and assembly. Designers and manufacturers need to consider the parting line’s location to ensure easy access for machining processes and proper alignment during assembly.

How to Determine the Location of Parting Line on Die Cast Components?

1. Symmetry: Whenever possible, parting lines are often positioned to create symmetrical halves of the die. Symmetry helps maintain balance in the die and can facilitate easier assembly and alignment.

2. Draft angles: The design of the die cast part should incorporate draft angles, which are tapered surfaces that facilitate easy removal of the part from the die. Parting lines are typically placed to utilize draft angles effectively.

3. Aesthetics and functional considerations: Parting lines are ideally placed in inconspicuous areas of the die cast component to minimize their visibility on the final part. However, other factors like part functionality or structural requirements may take priority over aesthetic considerations.

4. Wall thickness and complex features: Parting lines will generally follow the natural flow of the molten metal during the casting process. They are typically positioned in areas where the wall thickness is uniform and wherever the design allows for easy separation of the die halves without compromising complex features or tight tolerances.

5. Part complexity: For complex die cast components with multiple features, undercuts, or internal cavities, the parting line may need to be strategically placed to allow for the use of cores, sliders, or other advanced tooling features.