Nails are among the most essential fasteners in construction, woodworking, and furniture manufacturing — simple in appearance, yet highly specialized in function. From traditional woodwork to modern concrete structures, each nail type serves a unique purpose, offering specific advantages in strength, holding power, and application method. In this nails size chart, we’ll explore the most common types of nails, their features, specifications, and uses.

Types of Nails and Their Uses

- Steel Arranging Nails (ST)

Novel design, strong and efficient, ensures excellent engineering quality. Ideal for furniture making, sofas, wooden boxes, and other wood products. A modern replacement for common round nails. - Code Nails (K Nails / N Nails)

Fine and durable nails used for fixing fabrics or coverings. Common in sofa and chair manufacturing, leather upholstery, ceilings, and sheet attachments. - Concrete Steel Nails

Specifications: 7 mm – 35 mm.

Made of high-strength steel, resistant to bending, can be nailed directly into concrete or brick walls. For construction, masonry work, and fixing on concrete surfaces. - Wood Screws

Wood screws also known as wood thread screws. Combine metal and wood materials with strong grip. Widely applied in carpentry, cabinetry, and furniture assembly. Precision manufacturing via CNC machining ensures high durability. - Twist Nails

Specifications: 50 mm – 85 mm.

Twisted shank provides strong holding power and resists pull-out.

Uses: Suitable for drawers, wooden ceilings, and applications requiring strong nail force. - Straight Nails

Smooth, straight design made from 45# carbon steel; elegant and sturdy. For upholstery plywood, stripboard mounting, and light wood keel connections in furniture making. - Wire Nails

Specifications: 25 mm – 120 mm.

Smooth body with sharp ends, easy to drive and secure into wood. General purpose for woodworking and construction. - Self-Tapping Screws

Deep threads, high hardness, and excellent grip in metal materials. Joining metal parts, doors, windows, and iron sheets.

Low cost and strong performance. - Shoot Nails

Similar to concrete nails but require a nail gun for installation. Fastening wooden materials, frames, and panels; faster and more economical than manual nailing. - Bolts

For anchoring accessories and objects on walls or floors in construction. - Stapling Nails

Made of iron or copper, often nickel-plated to prevent rust. Binding paper documents and light fixing applications. - Special Steel Nails

High-strength nails capable of penetrating brick walls, cement blocks, and silicate structures.

Uses: Perfect for heavy construction and high-durability fixing. - Saddle Nails (Round Steel Tape U-Nails)

For fixing metal plates, wire meshes, indoor/outdoor hanging wires, and bundling wooden boxes.

What’s the Process of Nailing?

- Face Nailing

In this method, the nail is driven straight through the face (flat surface) of one board into another. This is the strongest and most reliable nailing method because the nail holds the two pieces tightly together across their faces. Commonly used for framing, decking, and structural assemblies where strength is a priority. - End Nailing

The nail is driven into the end grain of one piece of wood into the face of another. This is the weakest method, as nails driven into end grain do not hold well. Primarily used to temporarily align framing members until the structure gains strength from gravity, sheathing, or additional fastening. - Toe Nailing (Angled Nailing)

Nails are driven at an angle through one member into another, typically from the side or corner. When done correctly, it can be nearly as strong as face nailing and provides a tight joint. Ideal for framing corners, attaching studs to plates, or connecting joints where face nailing isn’t possible.

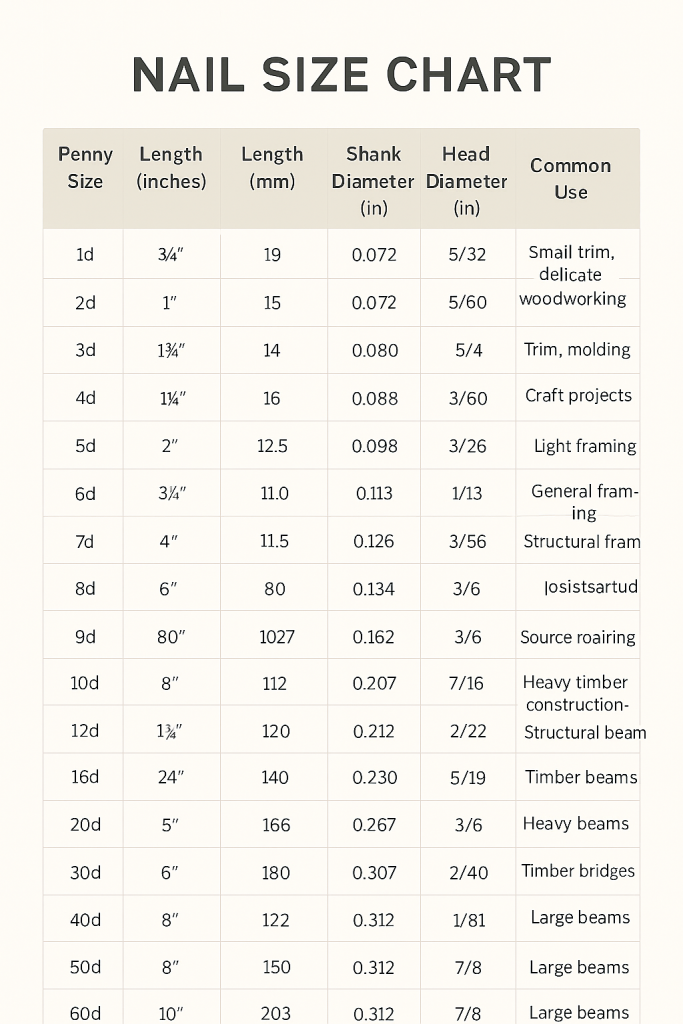

Nail Size Chart

| Penny Size (d) | Length (inches) | Length (mm) | Gauge | Shank Diameter (in) | Head Diameter (in) | Common Use |

|---|---|---|---|---|---|---|

| 1d | ¾″ | 19 mm | 15 | 0.072 | 5/32″ | Small trim, delicate woodworking, model making |

| 2d | 1″ | 25 mm | 15 | 0.072 | 5/32″ | Trim, molding, craft projects |

| 3d | 1¼″ | 32 mm | 14 | 0.080 | 3/16″ | Trim, small woodworking projects |

| 4d | 1½″ | 38 mm | 12.5 | 0.098 | ¼″ | Trim, light framing |

| 5d | 1¾″ | 44 mm | 12.5 | 0.098 | ¼″ | Trim, cabinet work, light framing |

| 6d | 2″ | 51 mm | 11.5 | 0.113 | 9/32″ | Light framing, fencing |

| 8d | 2½″ | 64 mm | 10.25 | 0.131 | 5/16″ | General framing, decking |

| 10d | 3″ | 76 mm | 9 | 0.148 | 3/8″ | Framing, fencing, general construction |

| 12d | 3¼″ | 83 mm | 9 | 0.148 | 3/8″ | Structural framing |

| 16d | 3½″ | 89 mm | 8 | 0.162 | 7/16″ | Structural framing, joists, studs |

| 20d | 4″ | 102 mm | 6 | 0.192 | ½″ | Heavy framing, beams |

| 30d | 4½″ | 114 mm | 5 | 0.207 | 9/16″ | Heavy framing, beams, posts |

| 40d | 5″ | 127 mm | 4 | 0.225 | 5/8″ | Heavy timber construction |

| 50d | 5½″ | 140 mm | 3 | 0.244 | 11/16″ | Heavy timber construction, structural beams |

| 60d | 6″ | 152 mm | 2 | 0.262 | ¾″ | Timber construction, heavy beams |

| 70d | 7″ | 178 mm | 1 | 0.283 | 13/16″ | Heavy timber framing, large beams |

| 80d | 8″ | 203 mm | 0 | 0.312 | 7/8″ | Timber bridges, docks, large structural members |

Nail Sizes Chart

Common Wood Nail Size Chart

| Nail Type | Penny Size (d) | Length (inches) | Gauge (diameter) | Typical Use |

|---|---|---|---|---|

| 2d | 2d | 1″ | 15.5 | Small trim, hobby woodwork |

| 3d | 3d | 1¼” | 14.5 | Light finishing, thin wood |

| 4d | 4d | 1½” | 14 | Trim, small woodworking |

| 5d | 5d | 1¾” | 12.5 | Interior trim, light joinery |

| 6d | 6d | 2″ | 11.5 | Framing small boards |

| 7d | 7d | 2¼” | 11 | Baseboards, general carpentry |

| 8d | 8d | 2½” | 10.25 | Common framing nails |

| 9d | 9d | 2¾” | 10 | Subfloor, decking |

| 10d | 10d | 3″ | 9 | Standard framing |

| 12d | 12d | 3¼” | 9 | Framing thicker wood |

| 16d | 16d | 3½” | 8 | Heavy framing, joists |

| 20d | 20d | 4″ | 6 | Structural, large beams |

| 30d | 30d | 4½” | 5 | Heavy timber construction |

| 40d | 40d | 5″ | 4 | Large posts and beams |

Sizes of Nails

- The “Penny” System (d)

This is the oldest and most traditional system, originating in England. The “penny” refers to the price per hundred nails centuries ago. A 10-penny (10d) nail cost 10 pence per hundred, a 16-penny (16d) cost 16 pence, and so on. Today, it simply denotes a nail’s length and, roughly, its shaft thickness. - Actual Measurement (Length & Gauge)

This modern system is more straightforward and is used for many specialized nails like finishing nails, brads, and roofing nails. It simply states the nail’s length and its shank diameter (gauge).

Length: Given in inches or millimeters.

Gauge: The wire diameter. The lower the gauge number, the thicker the nail.

A 15-gauge nail is very thick (used for finish nailers).

A 23-gauge nail is very thin (used for pin nailers, leaves almost no hole).

Common Examples:

Finishing Nails: Typically 15 or 16-gauge, lengths from 1″ to 2½”.

Brad Nails: Typically 18-gauge, lengths from ½” to 2″.

Pin Nails: Typically 23-gauge, lengths from ⅜” to 1⅜”.

Common Nail Lengths

| Type of Nail | Typical Length Range | Usage / Application |

|---|---|---|

| Finishing Nails | 1″ – 4″ (25 mm – 100 mm) | Trim work, molding, furniture assembly |

| Common Nails | 1″ – 6″ (25 mm – 150 mm) | Framing, construction, heavy-duty wood joining |

| Box Nails | 1½” – 3½” (38 mm – 90 mm) | Light construction, household repairs |

| Concrete Nails | ¾” – 4″ (20 mm – 100 mm) | Fastening wood or metal to concrete or masonry |

| Roofing Nails | ¾” – 1¾” (20 mm – 45 mm) | Attaching shingles, roofing felt, sheet materials |

| Brad Nails | ½” – 2″ (12 mm – 50 mm) | Fine woodworking, cabinetry, trim work |

| Framing Nails | 2″ – 3½” (50 mm – 90 mm) | Structural framing, decking |

| Masonry Nails | 1″ – 3″ (25 mm – 75 mm) | Attaching furring strips or baseboards to brick/concrete |

| Coil Nails | 1¼” – 2½” (32 mm – 65 mm) | Used in nail guns for pallets, fencing, and sheathing |

How to Choose the Right Screw Sizes?

A simple rule of thumb for general wood-to-wood nailing:

The nail should be long enough to penetrate the board you are attaching into by a distance at least equal to the thickness of the board you are attaching.

Example: If you are nailing a 1×4 (which is actually ¾” thick) to a stud, the nail should be at least 1½” long (¾” through the first board + ¾” into the stud). An 8d common nail (2½”) is a standard choice for this.

International Note (UK / Europe)

Outside North America, you will almost exclusively find nails measured in millimeters (mm) for length and sometimes millimeters for diameter. The “penny” system is rarely used.