How To Pretreat Cr12MoV Mold Steel | Diecasting-mould

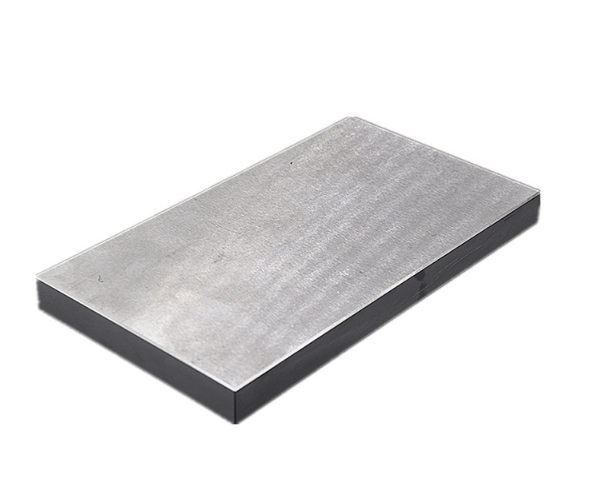

To increase hardness and wear resistance while also reducing distortion, Cr12MoV is a ledeburite cold work tool steel that was produced from Cr12 steel by incorporating more molybdenum and vanadium while simultaneously decreasing the amount of carbon in the steel. A cold mold with a heavy weight, large production, and complex shape is frequently manufactured with this tool. In this guide, we discuss methods on how to pretreat Cr12MoV mold steel.

How To Pretreat Cr12MoV Mold Steel

In order to reduce or eliminate the adverse effects of the uneven distribution of eutectic carbides in Cr12MoV steel on the mechanical properties and deformation of the mold, it is necessary to forge the raw materials. It is extremely difficult to improve the adverse effects of the uneven distribution of carbides simply by heat treatment without forging.

Cr12MoV steel has poor thermal conductivity, so the heating and cooling speed should not be too fast in the forging process, so as not to cause excessive temperature difference and cracking on the mold blank section. The forging temperature should be strictly controlled. If the stop forging temperature is too high, it will cause grain growth and coarsening and carbide aggregation, which may reduce the mechanical properties of the steel; If the stop forging temperature is too low, the steel will be scrapped due to poor plasticity and increased stress, which will easily lead to blank cracking.

In order to improve the uneven distribution of carbides in Cr12MoV steel, we must pay attention to the correct method in the forging process.

For molds with different performance, the allowable carbide distribution non-uniformity level after forging is sometimes different. Generally, the mold with high requirements for impact toughness and deformation should be controlled below level 3. If the requirements for hardness, strength, wear resistance, impact toughness and deformation are high, the level of uneven carbide distribution should be strictly controlled. Generally, it is required to be below level 2, and it is best to control level 1 ~ 1.5 for cold extrusion mold.

The uneven distribution of carbides is 1.5 grade and the grain size is 12 grade. From the test results, it can be seen that the level of uneven distribution of carbides in raw materials can be reduced by about 2 grades by conventional forging. Generally, after regular forging of large and medium-sized workpieces, the level of uneven distribution of carbides can be improved by about 1 ~ 1.5 grades at most. However, the use of forging waste heat quenching process can greatly reduce the level of uneven distribution of carbides, especially after increasing the last deformation, the forging waste heat quenching process can basically evenly distribute carbides in small samples. After quenching by forging waste heat, the carbide particle size becomes fine, the edges and corners become round, and the austenite grain size reaches ultra-fine. This double refining effect can make the plasticity and toughness of the workpiece rise synchronously, and the service life of tools and molds can be doubled. At the same time, it can save energy and shorten the production cycle.