Small and medium-sized die-casting enterprises are facing unprecedented operational difficulties, with increasingly fierce industry competition, reduced orders, reduced start-up rates, and meager profits.

How can small and medium-sized die casting enterprises cope with current difficulties and achieve healthy and sustainable development?

There are two trends in the die casting industry and even the manufacturing industry: the first trend is that profits are becoming thinner and thinner, and the second trend is the effect of orders gathering with large enterprises. The first trend is irreversible. From a cost perspective, labor costs and rental costs are gradually increasing. From a sales perspective, it is also an undeniable fact that casting buyers are reducing prices year by year. The second trend is also gradually forming. Many casting purchasers no longer manage and maintain many small die casting factories in order to reduce management costs, but choose several large die casting enterprises and give all orders of large and small sizes to these large enterprises. Through visits to thousands of die-casting enterprises and based on the above two trends, the following three suggestions are proposed for the transformation and sustainable development of small and medium-sized die-casting enterprises:

Firstly, specialize in one’s field of expertise or find a niche industry to specialize in products, reduce costs by improving efficiency, and improve quality by improving technology, becoming an expert in this niche industry.

Secondly, try to establish cooperative relationships with nearby large die-casting enterprises, undertake small product orders or small batch orders separated by large enterprises, serve large enterprises, and become an extension of production for large die-casting enterprises.

Thirdly, we need to build ourselves into an enterprise that can quickly deliver small batches and multiple varieties of die-casting parts to adapt to rapid market changes. Customers with small batches and multiple varieties can place orders with relatively high unit prices. If the enterprise can deliver quickly, it will be very competitive.

Opinions on the current market situation:

Firstly, the speed of product updates is too fast, which poses significant risks to project investment. Currently, the automotive industry has undergone profound changes, with traditional cars transitioning to new energy vehicles, and the new energy vehicles themselves are also rapidly iteratively upgrading. As a die-casting factory, due to a decrease in order and product demand, there has been a significant investment loss in mold, tooling, and other aspects in the early stage. During the initial investment and research and development, it was discovered that the estimated market and demand had disappeared during mass production.

Currently, the automotive industry has undergone profound changes, with traditional cars transitioning to new energy vehicles, and the new energy vehicles themselves are also rapidly iteratively upgrading. As a die-casting factory, due to a decrease in order and product demand, there has been a significant investment loss in mold, tooling, and other aspects in the early stage. During the initial investment and research and development, it was discovered that the estimated market and demand had disappeared during mass production.

Second, after many years of COVID-19 epidemic, the price of raw materials was high, the market demand was reduced, and the orders were shrunk. Die casting manufacturer faced unprecedented challenges in their operations. In addition, the national environmental protection policies have also brought great pressure to die-casting enterprises. In some regions, environmental regulations are very strict, and die-casting enterprises often encounter production stoppage and production restriction issues, leading to many die-casting enterprises going bankrupt.

Suggestions for small and medium-sized die-casting enterprises:

Firstly, open source. Continuously developing new customers and products. Developing new customers means constantly expanding the market. Developing new products means persisting in innovation, not sticking to old products or old things, but persistently developing new products. Die Casting attaches great importance to the research and development of new products. The research and development of a new product takes 2-3 years from project initiation to mass production, so the research and development of the new product should be planned in advance. This is also one of the secrets for Junying Die Casting to maintain counter trend growth in the current market environment.

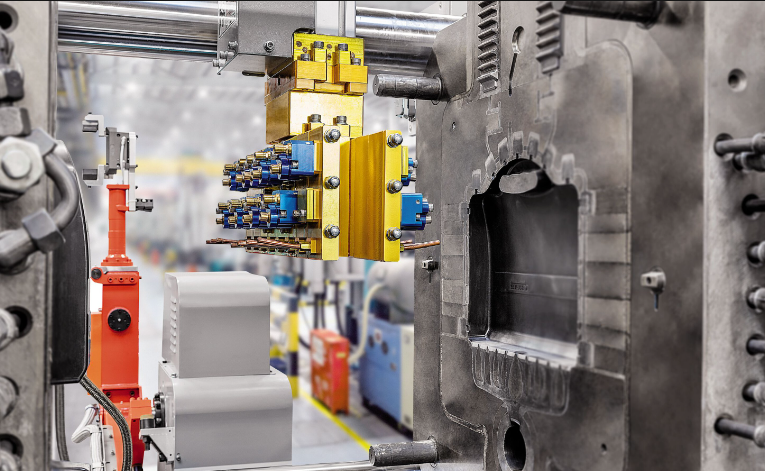

Secondly, throttling. Conduct comprehensive research on how to reduce business operating costs. At present, the prices of raw materials and auxiliary materials, including alloy materials, natural gas, electricity bills, etc., are all increasing, and labor prices are also rising. How to reduce costs from it? Firstly, the application of energy-saving technology involves introducing energy-saving die-casting equipment and furnaces, such as using servo energy-saving technology; Secondly, introduce automation equipment, implement fully automated production, improve production efficiency, enhance product stability and consistency, reduce defect rates, and reverse reduce production costs.

In addition, small and medium-sized enterprises also need to continue investing in new equipment and technologies, such as introducing new production equipment and eliminating outdated equipment, in order to improve production efficiency and enhance enterprise efficiency.

Thirdly, in the procurement of raw materials, it is important to pay attention to controlling costs, such as comparing products with other suppliers and closely monitoring price trends. During the production process, it is important to pay attention to leakage and reduce waste.