Hex nuts and bolts are fundamental fasteners used in nearly every industry, from construction and automotive to electronics and machinery. Selecting the proper hex nut is not just about finding the correct size; factors such as thread type, grade, torque values, and wrench compatibility all play essential roles. This article provides a detailed overview of hex nut and bolt dimensions, weight, grades, torque, and types, helping you make informed choices for your projects.

What is a Hex Nut?

A hex nut is a six-sided fastener designed for use with bolts and screws. Its shape offers an easy grip for wrenches, allowing secure tightening and even distribution of pressure when joining components. They are typically manufactured from materials like steel, brass, or stainless steel, and they come in various sizes and thread types for different applications.

What is a Hex Nut Used For?

Hex nuts are paired with bolts or screws to join materials, providing a secure and reliable connection. The six-sided design makes them easy to grip with standard wrenches or sockets. Hex nuts are widely used in construction, machinery, automotive, and a range of other applications where strong and durable fastening is required.

Hex Nut Types

A wide variety of hex nuts exist, each with specific features for different uses:

- Standard (Finish) Nut: The most widely used, suitable for general-purpose fastening.

- Jam Nut: About half the height of a standard nut, used in tight spaces or together with another nut for locking.

- Heavy Hex Nut: Thicker and wider than standard, offering greater strength for heavy-duty applications.

- Lock Nuts: Includes nylon insert lock nuts (with a nylon ring to prevent loosening), all-metal lock nuts, and prevailing torque nuts.

- Slotted Hex Nut: Features slots for a cotter pin, used where a locking device is needed, commonly in automotive assemblies.

- Castle Nut: Similar to slotted, but with a slotted collar for cotter pin installation.

- Specialty Nuts: Such as wing nuts (tool-free tightening), cap nuts (covered ends), coupling nuts (joining threaded rods), and knurled nuts (thumb-tightened).

Additional specialty nuts include reducer nuts, T-nuts for wood or plastics, tri-groove security nuts, and others designed for unique requirements.

How To Measure Hex Nut Size?

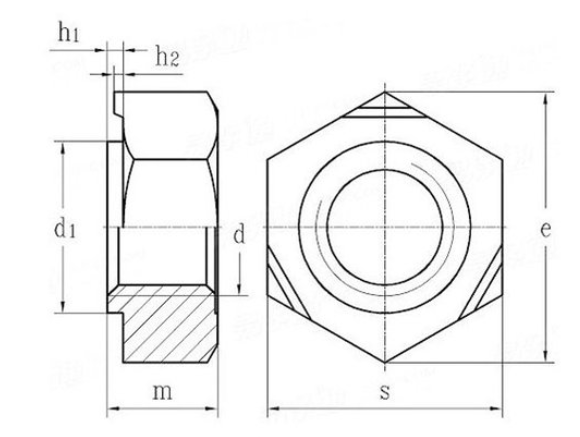

Measuring hex nut size involves several key dimensions:

- Diameter (d): The width of the threaded hole.

- Width Across Flats (s): The distance from one flat side of the nut to the opposite one, determining wrench size.

- Width Across Corners (e): The maximum span across the nut’s corners.

- Thickness (m): The nut’s height when lying flat.

In the imperial system, measurements are in inches and often represented as fractions (e.g., 7/16″). Metric nuts use millimeters (mm). For example, an M10 nut has a 10mm thread diameter.

To select the right nut, match the diameter to the bolt and ensure the across flats measurement is larger than the bolt diameter. Charts are widely available to match bolts and nuts correctly.

Standard Hex Nut Size Charts (Metric & Imperial)

Metric Hex Nut Size Chart in MM

| Nominal Nut Dia. | Thread Pitch | Width Across Flats, S | Width Across Corners, E | Thickness M | |||

|---|---|---|---|---|---|---|---|

| Max | Min | Max | Min | Max | Min | ||

| Standard Hex Nut Dimension Chart | |||||||

| M1.6 | 0.35 | 3.20 | 3.02 | 3.70 | 3.41 | 1.30 | 1.05 |

| M2 | 0.4 | 4.00 | 3.82 | 4.62 | 4.32 | 1.60 | 1.35 |

| M2.5 | 0.45 | 5.00 | 4.82 | 5.77 | 5.45 | 2.00 | 1.75 |

| M3 | 0.5 | 5.50 | 5.32 | 6.01 | 5.70 | 2.40 | 2.15 |

| M3.5 | 0.6 | 6.00 | 5.82 | 6.58 | 6.28 | 2.80 | 2.55 |

| M4 | 0.7 | 7.00 | 6.78 | 8.01 | 7.66 | 3.20 | 2.90 |

| M5 | 0.8 | 8.00 | 7.78 | 9.24 | 8.89 | 4.00 | 3.70 |

| M6 | 1 | 10.00 | 9.78 | 11.55 | 11.05 | 5.00 | 4.70 |

| M8 | 1.25 | 13.00 | 12.73 | 15.01 | 14.38 | 6.80 | 6.44 |

| M10 | 1.5 | 15.00 | 14.73 | 17.32 | 16.64 | 8.4 | 8.04 |

| M12 | 1.75 | 18.00 | 17.73 | 20.78 | 20.03 | 10.8 | 10.37 |

| M14 | 2 | 21.00 | 20.67 | 24.25 | 23.53 | 12.8 | 12.1 |

| M16 | 2 | 24.00 | 23.67 | 27.71 | 26.75 | 14.8 | 14.1 |

| M20 | 2.5 | 30.00 | 29.16 | 34.64 | 32.95 | 18.0 | 16.4 |

| M24 | 3 | 36.00 | 35.00 | 41.57 | 39.55 | 21.5 | 20.2 |

| M30 | 3.5 | 46.00 | 45.00 | 53.12 | 50.85 | 25.6 | 24.3 |

| M36 | 4 | 55.00 | 53.80 | 63.61 | 60.79 | 31.0 | 29.4 |

| M3 | 0.5 | 5.50 | 5.32 | 6.35 | 6.01 | 2.90 | 2.65 |

| M3.5 | 0.6 | 6.00 | 5.82 | 6.93 | 6.58 | 3.30 | 3.00 |

| M4 | 0.7 | 7.00 | 6.78 | 8.08 | 7.66 | 3.50 | 3.30 |

| M5 | 0.8 | 8.00 | 7.78 | 9.24 | 8.89 | 4.70 | 4.50 |

| M6 | 1 | 10.00 | 9.78 | 11.55 | 11.05 | 6.10 | 5.80 |

| M8 | 1.25 | 13.00 | 12.73 | 15.01 | 14.38 | 7.50 | 7.14 |

| M10 | 1.5 | 15.00 | 14.73 | 17.32 | 16.64 | 10.0 | 9.6 |

| M12 | 1.75 | 18.00 | 17.73 | 20.78 | 20.03 | 11.7 | 11.57 |

| M14 | 2 | 21.00 | 20.67 | 24.25 | 23.53 | 14.10 | 13.80 |

| M16 | 2 | 24.00 | 23.67 | 27.71 | 26.75 | 16.40 | 15.70 |

| M20 | 2.5 | 29.16 | 29.16 | 34.64 | 32.95 | 20.30 | 19.00 |

| M24 | 3 | 36.00 | 35.00 | 41.57 | 39.55 | 23.90 | 22.60 |

| M30 | 3.5 | 46.00 | 45.00 | 53.12 | 50.85 | 28.60 | 27.30 |

| M36 | 4 | 55.00 | 53.80 | 63.61 | 60.79 | 34.70 | 33.10 |

| Metric Hex Jam Nut Dimensions | |||||||

| M5 | 0.8 | 8.00 | 7.78 | 9.24 | 8.79 | 2.70 | 2.45 |

| M6 | 1 | 10.00 | 9.78 | 11.55 | 11.05 | 3.20 | 2.90 |

| M8 | 1.25 | 13.00 | 12.73 | 15.01 | 14.38 | 4.00 | 3.70 |

| aM10 | 1.5 | 15.00 | 14.73 | 17.32 | 16.64 | 5.00 | 4.70 |

| M10 | 1.5 | 16.00 | 15.73 | 18.48 | 17.77 | 5.00 | 4.70 |

| M12 | 1.75 | 18.00 | 17.73 | 20.78 | 20.03 | 6.00 | 5.70 |

| M14 | 2 | 21.00 | 20.67 | 24.25 | 23.35 | 7.00 | 6.42 |

| M16 | 2 | 24.00 | 23.67 | 27.71 | 26.75 | 8.00 | 7.42 |

| M20 | 2.5 | 30.00 | 29.16 | 34.64 | 32.95 | 10.00 | 9.10 |

| M24 | 3 | 36.00 | 35.00 | 41.57 | 39.57 | 12.00 | 10.90 |

| M30 | 3.5 | 46.00 | 45.00 | 53.12 | 51.85 | 15.00 | 13.90 |

| M36 | 4 | 55.00 | 53.80 | 63.51 | 60.89 | 18.00 | 16.90 |

| Metric Heavy Hex Nut Dimensions | |||||||

| M12 | 1.75 | 21.00 | 20.16 | 24.25 | 22.78 | 13.3 | 11.9 |

| M14 | 2 | 24.00 | 23.16 | 27.71 | 26.17 | 14.3 | 13.6 |

| M16 | 2 | 27.00 | 26.16 | 31.18 | 29.56 | 17.1 | 16.4 |

| M20 | 2.5 | 34.00 | 33.00 | 39.26 | 37.09 | 20.7 | 19.4 |

| M22 | 2.5 | 36.00 | 35.00 | 41.57 | 39.55 | 22.3 | 20.3 |

| M24 | 3 | 41.00 | 40.00 | 47.34 | 45.40 | 24.2 | 22.9 |

| M27 | 3 | 46.00 | 45.00 | 53.12 | 50.85 | 26.3 | 24.8 |

| M30 | 3.5 | 50.00 | 49.00 | 57.74 | 55.37 | 29.1 | 27.6 |

| M36 | 4 | 60.00 | 58.80 | 69.28 | 66.44 | 36.6 | 35.0 |

| M42 | 4.5 | 70.00 | 67.90 | 80.83 | 77.41 | 42.0 | 40.4 |

| M48 | 5 | 80.00 | 77.00 | 92.38 | 88.46 | 48.0 | 46.4 |

| M56 | 5.5 | 90.00 | 87.00 | 103.92 | 99.41 | 56.0 | 54.1 |

| M64 | 6 | 100.00 | 96.80 | 115.47 | 110.35 | 64.0 | 62.1 |

| M72 | 6 | 110.00 | 106.40 | 127.02 | 121.30 | 72.0 | 70.0 |

| M80 | 6 | 120.00 | 116.00 | 138.56 | 132.24 | 78.1 | 110.2 |

| M90 | 6 | 135.00 | 130.00 | 155.88 | 148.77 | 87.8 | 124.0 |

| M100 | 6 | 150.00 | 145.00 | 173.21 | 165.30 | 100.0 | 97.8 |

| Standard Slotted Hex Nut Dimensions (per ANSI B18.2.4M) | |||||||

| M5 | 0.8 | 8.00 | 7.78 | 9.24 | 8.79 | 5.10 | 4.80 |

| M6 | 1 | 10.00 | 9.78 | 11.55 | 11.05 | 5.70 | 5.40 |

| M8 | 1.25 | 13.00 | 12.73 | 15.01 | 14.38 | 7.50 | 7.14 |

| aM10 | 1.5 | 15.00 | 14.73 | 17.32 | 16.64 | 7.60 | 7.14 |

| M10 | 1.5 | 16.00 | 15.73 | 18.48 | 17.77 | 9.30 | 8.94 |

| M12 | 1.75 | 18.00 | 17.73 | 20.78 | 20.03 | 11.60 | 11.57 |

| M14 | 2 | 21.00 | 20.67 | 24.25 | 23.35 | 14.10 | 13.10 |

| M16 | 2 | 24.00 | 23.67 | 27.71 | 26.75 | 16.40 | 15.70 |

| M20 | 2.5 | 30.00 | 29.16 | 34.64 | 32.95 | 19.00 | 17.77 |

| M24 | 3 | 36.00 | 35.00 | 41.57 | 39.55 | 23.90 | 22.60 |

| M30 | 3.5 | 46.00 | 45.00 | 53.12 | 51.85 | 29.10 | 27.30 |

| M36 | 4 | 55.00 | 53.80 | 63.51 | 60.79 | 34.70 | 33.10 |

Imperial Hex Nut Size Chart in Inches

| Nominal or Basic Major Diameter of Thread | Width Across Flats (F) | Width Across Corners (G) | Thickness of Hex Nuts (H) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Basic | Max | Min | Max | Min | Basic | Max | Min | ||

| Hex Nut Sizes – Hex Nut Dimensions (ANSI/ASME B18.2.2) | |||||||||

| 1/4 | 0.2500 | 7/16 | 0.438 | 0.428 | 0.505 | 0.488 | 7/32 | 0.226 | 0.212 |

| 5/16 | 0.3125 | 1/2 | 0.500 | 0.489 | 0.577 | 0.557 | 17/64 | 0.273 | 0.258 |

| 3/8 | 0.3750 | 9/16 | 0.562 | 0.551 | 0.650 | 0.628 | 21/64 | 0.337 | 0.320 |

| 7/16 | 0.4375 | 11/16 | 0.688 | 0.675 | 0.794 | 0.768 | 3/8 | 0.385 | 0.365 |

| 1/2 | 0.5000 | 3/4 | 0.750 | 0.736 | 0.866 | 0.840 | 7/16 | 0.448 | 0.427 |

| 9/16 | 0.5625 | 7/8 | 0.875 | 0.861 | 1.010 | 0.982 | 31/64 | 0.496 | 0.473 |

| 5/8 | 0.6250 | 15/16 | 0.938 | 0.922 | 1.083 | 1.051 | 35/64 | 0.559 | 0.535 |

| 3/4 | 0.7500 | 1-1/8 | 1.125 | 1.088 | 1.299 | 1.240 | 41/64 | 0.665 | 0.617 |

| 7/8 | 0.8750 | 1-5/16 | 1.312 | 1.269 | 1.516 | 1.447 | 3/4 | 0.776 | 0.724 |

| 1 | 1.0000 | 1-1/2 | 1.500 | 1.450 | 1.732 | 1.653 | 55/64 | 0.887 | 0.831 |

| 1-1/8 | 1.1250 | 1-11/16 | 1.688 | 1.631 | 1.949 | 1.859 | 31/32 | 0.999 | 0.939 |

| 1-1/4 | 1.2500 | 1-7/8 | 1.875 | 1.812 | 2.165 | 2.066 | 1-1/16 | 1.094 | 1.030 |

| 1-3/8 | 1.3750 | 2-1/16 | 2.062 | 1.994 | 2.382 | 2.273 | 1-11/64 | 1.206 | 1.138 |

| 1-1/2 | 1.5000 | 2-1/4 | 2.250 | 2.175 | 2.598 | 2.480 | 1-19/32 | 1.317 | 1.245 |

| 1-5/8 | 1.6250 | 2-7/16 | 2.438 | 2.356 | 2.815 | 2.686 | 1-25/64 | 1.429 | 1.353 |

| 1-3/4 | 1.7500 | 2-5/8 | 2.625 | 2.538 | 3.031 | 2.893 | 1-1/2 | 1.540 | 1.460 |

| 2 | 2.0000 | 3 | 3.000 | 2.900 | 3.464 | 3.306 | 1-23/32 | 1.763 | 1.675 |

| 2-1/4 | 2.2500 | 3-3/8 | 3.375 | 3.263 | 3.897 | 3.719 | 1-15/16 | 1.986 | 1.890 |

| 2-1/2 | 2.5000 | 3-3/4 | 3.750 | 3.625 | 4.133 | 4.066 | 2-5/32 | 2.209 | 2.105 |

| 2-3/4 | 2.7500 | 4-1/8 | 4.125 | 3.988 | 4.763 | 4.456 | 2-3/8 | 2.431 | 2.319 |

| 3 | 3.0000 | 4-1/2 | 4.500 | 4.350 | 5.196 | 4.959 | 2-19/32 | 2.654 | 2.534 |

| Heavy Hex Nuts: Dimensions (ANSI/ASME B18.2.2) | |||||||||

| 1/4 | 0.2500 | 1/2 | 0.500 | 0.488 | 0.577 | 0.556 | 15/64 | 0.250 | 0.218 |

| 5/16 | 0.3125 | 9/16 | 0.562 | 0.546 | 0.650 | 0.622 | 19/64 | 0.314 | 0.280 |

| 3/8 | 0.3750 | 11/16 | 0.688 | 0.669 | 0.794 | 0.763 | 23/64 | 0.377 | 0.341 |

| 7/16 | 0.4375 | 13/16 | 0.812 | 0.789 | 0.866 | 0.830 | 27/64 | 0.404 | 0.363 |

| 1/2 | 0.5000 | 7/8 | 0.875 | 0.850 | 1.010 | 0.969 | 31/64 | 0.504 | 0.464 |

| 9/16 | 0.5625 | 15/16 | 0.938 | 0.909 | 1.083 | 1.037 | 35/64 | 0.568 | 0.526 |

| 5/8 | 0.6250 | 1-1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 39/64 | 0.631 | 0.587 |

| 3/4 | 0.7500 | 1-1/4 | 1.250 | 1.212 | 1.443 | 1.382 | 47/64 | 0.758 | 0.710 |

| 7/8 | 0.8750 | 1-7/16 | 1.438 | 1.394 | 1.589 | 1.557 | 55/64 | 0.885 | 0.833 |

| 1 | 1.0000 | 1-5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 1 | 1.012 | 0.956 |

| 1-1/8 | 1.1250 | 1-13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 1-7/64 | 1.139 | 1.079 |

| 1-1/4 | 1.2500 | 2 | 2.000 | 1.938 | 2.309 | 2.209 | 1-7/32 | 1.251 | 1.187 |

| 1-3/8 | 1.3750 | 2-3/16 | 2.188 | 2.119 | 2.525 | 2.416 | 1-15/32 | 1.310 | 1.243 |

| 1-1/2 | 1.5000 | 2-3/8 | 2.375 | 2.300 | 2.742 | 2.622 | 1-35/64 | 1.505 | 1.433 |

| 1-5/8 | 1.6250 | 2-9/16 | 2.562 | 2.481 | 2.959 | 2.828 | 1-19/32 | 1.632 | 1.556 |

| 1-3/4 | 1.7500 | 2-3/4 | 2.750 | 2.662 | 3.175 | 3.035 | 1-23/32 | 1.759 | 1.679 |

| 2 | 2.0000 | 3-1/8 | 3.125 | 3.025 | 3.608 | 3.449 | 1-31/32 | 2.013 | 1.925 |

| 2-1/4 | 2.2500 | 3-1/2 | 3.500 | 3.328 | 4.044 | 3.862 | 2-5/32 | 2.251 | 2.153 |

| 2-1/2 | 2.5000 | 3-7/8 | 3.875 | 3.750 | 4.474 | 4.275 | 2-29/64 | 2.505 | 2.401 |

| 2-3/4 | 2.7500 | 4-1/4 | 4.250 | 4.112 | 4.907 | 4.688 | 2-45/64 | 2.759 | 2.647 |

| 3 | 3.0000 | 4-5/8 | 4.625 | 4.475 | 5.340 | 5.102 | 2-61/64 | 3.013 | 2.893 |

| 3-1/4 | 3.2500 | 5 | 5.000 | 4.838 | 5.774 | 5.515 | 3-1/16 | 3.252 | 3.124 |

| 3-1/2 | 3.5000 | 5-3/8 | 5.375 | 5.220 | 6.207 | 5.928 | 3-7/16 | 3.506 | 3.370 |

| 3-3/4 | 3.7500 | 5-3/4 | 5.750 | 5.562 | 6.341 | 6.137 | 3-11/16 | 3.760 | 3.616 |

| 4 | 4.0000 | 6-1/8 | 6.125 | 5.925 | 7.073 | 6.755 | 3-15/16 | 4.014 | 3.862 |

Standard Hex Nut Weight Chart

The weight of a hex nut varies by size, material, and thread pitch. Below is an approximate weight chart for common metric hex nuts made from steel:

Metric Hex Nut Weight Chart (in Kilo)

Weights are in kilograms per 1,000 pieces unless otherwise specified. All weights are approximations and strictly informative.

| Size | din 934 hEX nUT | OLD SPEC IS 1363/67 | NEW SPEC IS 1363/92 | HEIGHT = DIA NUTS | HEX LOCK NUTS IS 1364-84 | HSS NUTS IS: 6623 | Castle Nuts IS 2232-67 | Nylock Nuts DIN 985 |

|---|---|---|---|---|---|---|---|---|

| M1 | 0.030 | |||||||

| M1.2 | 0.054 | |||||||

| M1.4 | 0.063 | |||||||

| M1.6 | 0.076 | |||||||

| M2 | 0.142 | 0.011 | ||||||

| M2.5 | 0.280 | |||||||

| M3 | 0.384 | 0.033 | 0.050 | |||||

| M3.5 | 0.514 | |||||||

| M4 | 0.81 | 0.067 | 0.112 | 0.100 | ||||

| M5 | 1.23 | 0.111 | 0.080 | 0.230 | 0.140 | |||

| M6 | 2.50 | 0.232 | 0.120 | 0.316 | 0.240 | |||

| M7 | 3.12 | 0.294 | 0.396 | 0.300 | ||||

| M8 | 5.20 | 0.482 | 0.300 | 0.735 | 0.510 | |||

| M10 | 11.6 | 1.020 | 0.909 | 1.282 | 0.670 | 1.580 | 1.060 | |

| M12 | 17.3 | 1.590 | 1.389 | 1.942 | 1.090 | 2.000 | 1.720 | |

| M14 | 25.0 | 2.400 | 3.049 | 1.680 | 2.700 | 2.600 | ||

| M16 | 33.3 | 3.081 | 3.333 | 3.906 | 1.800 | 6.040 | 3.890 | 3.400 |

| M18 | 49.4 | 4.448 | 5.814 | 2.690 | 5.750 | 4.500 | ||

| M20 | 64.4 | 6.031 | 6.667 | 7.519 | 3.300 | 11.530 | 7.520 | 6.500 |

| M22 | 79 | 7.143 | 8.929 | 9.091 | 3.890 | 14.280 | 9.300 | 7.500 |

| M24 | 110 | 10.309 | 12.500 | 12.821 | 5.100 | 19.770 | 13.100 | 10.000 |

| M27 | 165 | 15.432 | 18.657 | 8.150 | 28.230 | 19.200 | 16.200 | |

| M30 | 223 | 21.645 | 26.596 | 10.400 | 36.500 | 26.400 | 21.200 | |

| M33 | 288 | 27.174 | 34.483 | 14.300 | 33.330 | 31.700 | ||

| M36 | 393 | 37.037 | 43.860 | 17.600 | 28.180 | 44.700 | 41.500 | |

| M39 | 502 | 47.619 | 57.471 | 24.000 | 58.400 | 49.900 | ||

| M42 | 652 | 57.471 | 73.529 | 27.500 | 71.000 | 62.800 | ||

| M45 | 800 | 72.464 | 92.593 | 37.000 | 86.000 | 77.100 | ||

| M48 | 977 | 92.593 | 113.636 | 42.800 | 106.000 | 99.800 | ||

| M52 | 1220 | 108.696 | 138.889 | 52.000 | 130.000 | |||

| M56 | 1420 | 131.579 | 166.667 | |||||

| M60 | 1690 | 161.290 | 192.308 | |||||

| M64 | 1980 | 185.185 | 227.273 | |||||

| M68 | 2300 | |||||||

| M72 | 2670 | 250.000 | 312.500 | |||||

| M76 | 3040 | |||||||

| M80 | 3440 | 333.333 | ||||||

| M85 | 3930 | |||||||

| M90 | 4930 | 454.545 | ||||||

| M100 | 6820 | 625.000 |

Imperial Hex Nut Weight Chart (in lbs)

Pounds (lbs) per 100 pieces.

| Size | Finished Hex | Heavy Hex | Finished Jam | Heavy Hex Jam |

|---|---|---|---|---|

| 1/2″ | 3.750 | 6.540 | 2.620 | 4.000 |

| 5/8″ | 7.330 | 11.900 | 4.930 | 6.960 |

| 3/4″ | 11.900 | 19.300 | 7.700 | 11.000 |

| 7/8″ | 19.000 | 29.700 | 12.000 | 16.700 |

| 1″ | 28.300 | 42.500 | 17.600 | 23.500 |

| 1-1/8″ | 40.300 | 59.200 | 24.700 | 32.400 |

| 1-1/4″ | 54.300 | 78.600 | 36.100 | 45.800 |

| 1-3/8″ | 73.000 | 102.000 | 47.900 | 59.300 |

| 1-1/2″ | 94.300 | 131.000 | 60.900 | 74.800 |

| 1-5/8″ | 162.000 | 91.600 | ||

| 1-3/4″ | 151.000 | 204.000 | 100.000 | 114.000 |

| 1-7/8″ | 241.000 | 134.000 | ||

| 2″ | 224.000 | 299.000 | 140.000 | 165.000 |

| 2-1/4″ | 419.000 | 227.000 | ||

| 2-1/2″ | 564.000 | 332.000 | ||

| 2-3/4″ | 738.000 | 429.000 | ||

| 3″ | 950.000 | 545.000 | ||

| 3-1/4″ | 1194.000 | 651.000 | ||

| 3-1/2″ | 1526.000 | 851.000 | ||

| 3-3/4″ | 1812.000 | 1005.000 | ||

| 4″ | 2180.000 | 1200.000 |

Standard Hex Nut Grade Chart

Hex nuts are classified by grade or property class, which indicates their material strength and application suitability.

Metric Grades

- Class 4.6: Low carbon steel, proof load 225 MPa, tensile strength 400 MPa, Rockwell B67-95. Suited for low-stress uses.

- Class 8.8: Medium carbon steel, quenched and tempered, proof load 600 MPa, tensile strength 830 MPa, Rockwell HRC 22-34. Used for moderate strength needs.

- Class 10.9: Alloy steel, quenched and tempered, proof load 830 MPa, tensile strength 1040 MPa, Rockwell HRC 32-39. For high-strength applications.

- Class 12.9: Highest strength, proof load 970 MPa, tensile strength 1220 MPa, Rockwell HRC 39-44. Used in aerospace, military, and heavy machinery.

Imperial Grades

- Grade 2: Low or medium carbon steel, used in non-structural, low-stress settings.

- Grade 5: Medium carbon steel, quenched and tempered, for automotive and machinery.

- Grade 8: Alloy steel, high-strength, used in demanding applications.

Each grade has its own torque requirements, so always verify before tightening.

How To Tighten a Hex Nut?

Tightening a hex nut correctly is vital for safety and performance. Use a wrench that matches the width across flats of the nut. Start the nut by hand to avoid cross-threading and finish tightening with the wrench. For precise applications, use a torque wrench set to the recommended value for the nut’s grade and size.

For applications needing extra security, use lock nuts or a second “jam” nut to resist loosening from vibration. In some cases, slotted or castle nuts are combined with cotter pins to lock the assembly.

Standard Hex Nut Wrench Size Chart

Selecting the correct wrench is key for efficient and safe tightening:

| Nut Size (Metric) | Wrench Size (mm) |

|---|---|

| M4 | 7 |

| M5 | 8 |

| M6 | 10 |

| M8 | 13 |

| M10 | 17 |

| M12 | 19 |

| M16 | 24 |

| M20 | 30 |

| Nut Size (Imperial) | Wrench Size (in) |

|---|---|

| 1/4″-20 | 7/16 |

| 5/16″-18 | 1/2 |

| 3/8″-16 | 9/16 |

| 1/2″-13 | 3/4 |

| 5/8″-11 | 15/16 |

| 3/4″-10 | 1-1/8 |

Always match the wrench to the nut’s flats, not the corners, to avoid rounding.

Standard Hex Nut Torque Charts

Applying the correct torque ensures optimal fastening without damaging the nut or bolt. Torque values depend on nut size, grade, and lubrication.

Why are torque standards necessary?

- Proper torque ensures secure connections and prevents loosening.

- Overtightening can damage threads or crack nuts.

- Undertightening leads to loosening and potential failure.

Example Torque Chart (for dry, plain steel nuts):

| Thread Size | Grade 8 (ft-lb) | Grade 5 (ft-lb) | Grade 2 (ft-lb) |

|---|---|---|---|

| 1/4″-20 | 12 | 8 | 6 |

| 5/16″-18 | 25 | 17 | 11 |

| 3/8″-16 | 45 | 31 | 19 |

| 1/2″-13 | 120 | 75 | 49 |

| 5/8″-11 | 230 | 150 | 95 |

| 3/4″-10 | 400 | 260 | 145 |

Metric Example (Class 8.8, dry):

| Thread Size | Torque (Nm) |

|---|---|

| M6 | 10 |

| M8 | 25 |

| M10 | 49 |

| M12 | 86 |

| M16 | 210 |

| M20 | 410 |

Always consult the manufacturer’s specifications for your application, especially if nuts are lubricated or plated, as this affects torque values.