Die Casting vs Metal Stamping - Difference Between Casting and Stamping | Diecasting-mould

The creation of plenty of metal forming processes allows the metal products to be made in various methods, also brings the difficulty of choice. Each metal manufacturing technique has its own strength and weakness, in this article, we want to talk about the difference between casting and stamping, to find their applicability and make a better choice when die casting vs metal stamping.

What is Metal Stamping?

Stamping, also called pressing, is a sheet metal forming process to transform the materials into different shapes. The flat sheet metal in either blank or coil form is usually placed into a stamping press where a tool and die surface forms the metal into a net shape. The material to be stamped is generally put between die sections, utilizing the pressure to shape and shear the material into the final component with the desired geometry. Stamping is usually carried out on sheet metal, but can also work with other materials. The metal stamping process involves a variety of manufacturing processes, including punching, blanking, embossing, bending, flanging, and more. It can be a single-stage operation or go through a series of stages with multiple techniques. Stamping is a cost-effective and high-speed metal fabrication process that is suitable for low or high volume production runs.

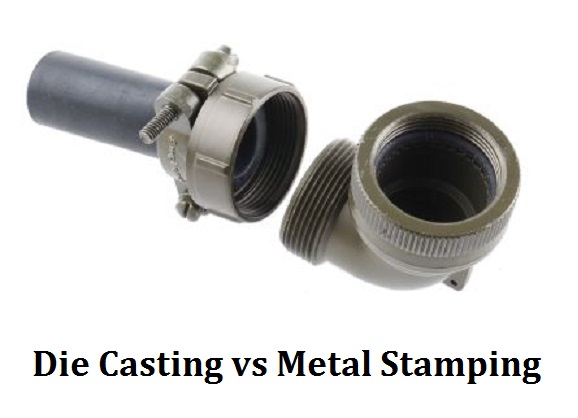

Die Casting vs Metal Stamping - Difference Between Casting and Stamping

When you have the need for manufacturing metal parts, which process should you choose? Die casting and metal stamping are both metal forming process, what’s the difference between them?

1. Applicability. Metal stamping is a good choice for both ferrous and non-ferrous materials, while die casting is usually performed on non-ferrous materials, only can be used on a few types of ferrous metals.

2. Cost. For simple parts, stamping can be more economical than die casting, the stamping dies are also less costly, however, with the increase of complexity, the cost of metal stamping will be raised because of the use of more additional components.

3. Waste. Die casting is more environmental-friendly. Metal stamping produces a significant amount of unused scrap metal and waste, which generated by die casting is much lower, in addition, the metal cast scrap is easier to recycle.

4. Complexity. For a large batch of complex metal parts, die casting is a more ideal solution. It can produce parts with extremely complex shapes and maintain high accuracy and affordable cost.

5. Material. Die casting usually uses metal ingots or billets, while stamping needs sheet metals in blanks or coils.

6. Condition. In the die casting process, the metal should be heated beyond its melting point to the molten state, while stamping is almost always a cold-forming process.

7. Machine. Die casting is conducted in a die casting machine of a foundry while the stamping process is done in a stamping machine or pressing machine.

8. Mold. The service life of die casting mold is longer if it’s well maintained, a complex stamping part needs several sets of dies to shape, resulting in increased cost.

Work with DIECASTING-MOULD, you don’t need to worry about the cost of die casting molds, die casting services at Junying will offer you high quality and cost-effective castings in a short lead time, our metal casting parts are widely used for an extensive range of applications.