Die casting is a versatile manufacturing process that has been used for decades to create high-quality metal parts. However, with changing demands and expectations from customers and stakeholders, the industry is constantly evolving to meet new challenges and opportunities. In this article, we will explain how the die casting industry is adapting to meet the demands of a changing industry.

Die Casting: Meeting the Demands of a Changing Industry

Material Selection

Material selection is a critical aspect of die casting, as the performance and properties of the final product depend on the material used. In recent years, there has been a growing demand for lightweight and high-strength materials in various industries, such as automotive and aerospace. As a result, the die casting industry is exploring new materials, such as magnesium, aluminum, and composites, to meet these demands. Additionally, sustainable materials and processes are becoming increasingly important, with manufacturers looking for ways to reduce the environmental impact of manufacturing.

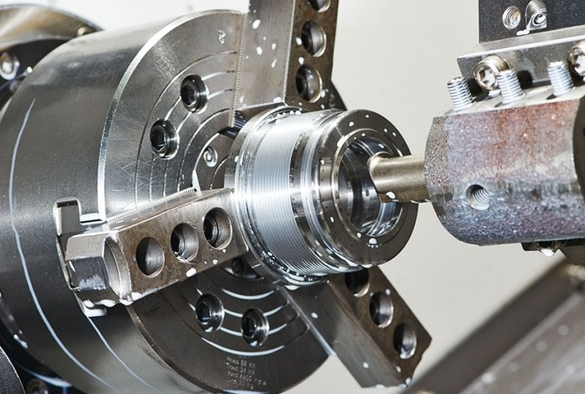

Technology Advancements

Advancements in technology have revolutionized the die casting industry, with new machinery, software, and processes improving efficiency, accuracy, and sustainability. For example, simulation software is being used to model and simulate the die casting process, allowing for greater accuracy and optimization of the process parameters. Additionally, automation and robotics are being used to improve productivity and reduce the risk of defects. Additive manufacturing, or 3D printing, is also being explored as a way to produce molds and prototypes more quickly and cost-effectively.

Customization and Flexibility

The demand for customized products and shorter lead times is increasing in various industries, such as consumer goods and electronics. The die casting industry is responding to this demand by exploring new methods for customization and flexibility. For example, multi-slide die casting is a process that allows for greater flexibility and customization in part design and production. Additionally, advances in materials and technology have made it possible to produce parts with complex geometries and features, allowing for greater customization.

Quality Control

The quality of die cast parts is critical for many applications, such as automotive and aerospace. The die casting industry is implementing new methods for quality control, such as advanced inspection technologies, statistical process control, and real-time monitoring of process parameters. These methods help to ensure that the final product meets the required specifications and standards.

Collaboration and Innovation

Collaboration and innovation are essential for the continued growth and success of the die casting industry. Manufacturers are collaborating with customers, suppliers, and other stakeholders to identify new opportunities and solutions. Innovation is also key, with manufacturers investing in research and development to explore new materials, technologies, and applications. By working together and pushing the boundaries of what is possible, the die casting industry can continue to meet the demands of a changing industry.

In conclusion, the die casting industry is adapting to meet the demands of a changing industry through material selection, technology advancements, customization and flexibility, quality control, and collaboration and innovation. By embracing these changes and investing in new solutions, the industry can continue to thrive and provide high-quality metal parts for various applications.

Industry Trends and Future Outlook

As the die casting industry continues to evolve and adapt, there are several trends and future outlooks that are worth considering. Here are some of the key trends and predictions for the die casting industry:

-Increased use of lightweight materials: The demand for lightweight materials, such as magnesium and aluminum, is expected to increase in various industries, including automotive and aerospace. This trend is likely to continue as manufacturers look for ways to improve fuel efficiency and reduce emissions.

-Greater use of automation and robotics: Automation and robotics are already being used in the die casting industry to improve productivity and reduce defects. This trend is likely to continue as technology continues to evolve and as manufacturers look for ways to reduce costs and improve efficiency.

-Growing demand for sustainable manufacturing: The demand for sustainable manufacturing is expected to increase as consumers and regulators become more focused on environmental issues. The die casting industry is well positioned to meet this demand through the use of recycled materials, energy-efficient processes, and reduced waste.

-Increased customization and flexibility: The demand for customized products and shorter lead times is expected to continue to grow in various industries. The die casting industry is well positioned to meet this demand through the use of multi-slide die casting and other advanced techniques.

-Greater use of digital technologies: Digital technologies, such as simulation software and real-time monitoring, are already being used in the die casting industry to improve efficiency and quality. This trend is likely to continue as technology continues to evolve and as manufacturers look for ways to optimize the process and reduce the risk of defects.