China Die Casting Mold Market Competition Is Increasing | Diecasting-mould

Die casting mold is becoming more and more competitive in the market. In this guide, we analyze the intensification of market competition in die casting mold manufacturers.

China Die Casting Mold Market Competition

The competition in China’s mold market is intensifying, the technical content of mold is improving, and there are more and more molds belonging to high-tech products. It is understood that there are four kinds of molds that have been listed in the export catalogue of China’s high-tech products by relevant state departments. In fact, the technical content of many molds has exceeded these four molds, such as progressive molds for auto parts, precision multi station progressive molds, stamping molds for large and complex panels of cars, pouring molds for automatic auto interior trim parts, hot pressing molds for high-strength plates, etc. With the development of high-tech, more and more mold manufacturing enterprises are recognized as high-tech enterprises by relevant departments of governments at all levels.

According to the preliminary statistics of China mould association, there are 7 national high-tech enterprises in the mould industry and nearly 100 provincial and municipal high-tech enterprises. The trend of international mold capital transfer to China is very obvious, and the prospect of mold export is very good. As China’s molds, especially medium and low-grade molds, have great price advantages in the international market, and the price of some molds is even only a fraction of that in the international market. In addition, China has low-cost high-quality labor resources and better technical foundation and infrastructure supporting facilities. Therefore, the amount of foreign investment in China’s mold industry has increased year by year in recent years, More and more multinational companies purchase molds in China. It can be seen that the development of China’s die casting mold industry in the future will gain a good momentum.

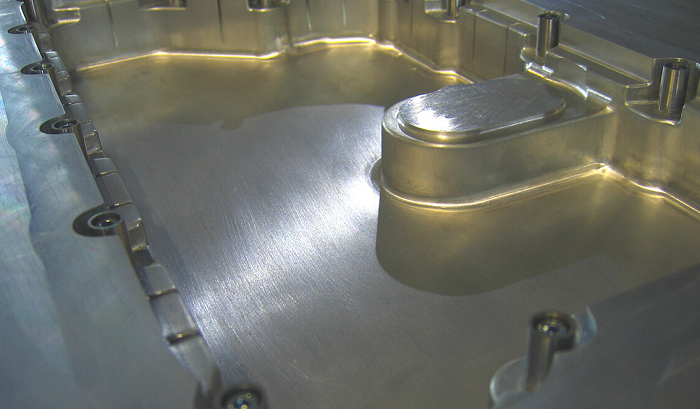

It is reported that die-casting mold enterprises usually pay great attention to accelerating the pace of new product development. At the same time, die-casting manufacturers not only meet their domestic needs, but also actively carry out the marketing strategy of vigorously entering the international market. In addition, in addition to vigorously promoting a good marketing strategy, in terms of mold price and manufacturing cycle, the price of foreign molds is generally 5 ~ 10 times that of domestic molds, and the manufacturing cycle is 2 ~ 3 times. In this regard, China’s foundry industry has a certain price and manufacturing cycle advantage over foreign countries. Secondly, good die-casting molds can bring great advantages to the company. It should be said that there are many benefits. Die casting molds are always repaired and modified, and even scrapped in the end. It takes a lot of time and manpower, and there are a lot of redundant costs.

Most people think that it is impossible to design the die-casting die in place at one time (the design of gating system), and it must be modified again later. In fact, this is a serious mistake. Now the design defects can be analyzed by using advanced CAE simulation analysis software (such as FLOW3D and magmafot). The vigorous development of China’s automobile, aviation and other related industries in recent years has provided huge market demand for the die-casting die industry, which is an important factor driving economic growth, The vigorous development of die casting mold related industries provides a broad market space for it.