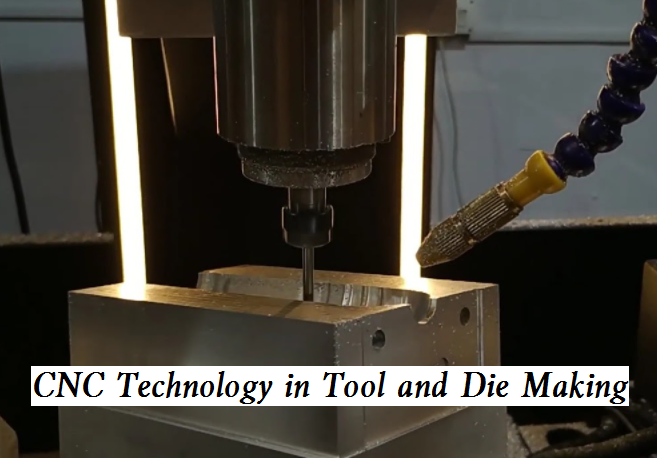

The CNC manufacturing service is extensively used in the production of various mechanical parts and products, including mold making. What benefits does CNC technology bring and what types of CNC machining are applied in die making/manufacturing?

Benefits of CNC Technology in Tool and Die Manufacturing/Making

1. Improve the automation of manufacturing and reduce errors

Many mold manufacturing companies in China use CNC machine tools and other advanced equipment to improve their production efficiency, while avoiding the impact of human errors on the products, and more effectively improving the accuracy of machined parts. In addition, the production efficiency and quality of products can be improved by improving the automatic production and manufacturing level of machinery and strengthening the efficiency of tool change and tool adjustment of CNC machines.

2. Improve the manufacturing efficiency of tools and dies

Using CNC machining technology in mold making can also improve manufacturing efficiency. At the same time, through the effective control of internal parts and tools of CNC machine tools by relevant personnel, as well as the application of relevant technologies, relevant personnel can be urged to write corresponding CNC programs according to the characteristics of parts, and then use more versatile molds for production.

Applications of CNC Technology in Mold Manufacturing/Making

1. CNC milling

Many products in the mechanical manufacturing industry are mainly curved surfaces, and plane structure products and molds are rare. CNC milling technology plays a very important role in the mechanical manufacturing industry. It is mainly used to fully process the curved surface or concave-convex surface in the manufacturing process of mechanical mold. Therefore, in the production and processing of mechanical products, the method of CNC milling should be adopted, so that the production and processing of mechanical products can be carried out more effectively, and the production efficiency and quality of mechanical products can be improved.

2. CNC EDM

The results show that CNC EDM technology plays an important role in the manufacturing and processing of mechanical products; At the same time, CNC EDM technology is also widely used in the manufacturing process of mechanical products. CNC EDM technology needs to continuously improve its machining accuracy to ensure higher machining efficiency for the production and processing of mechanical products, so as to improve the production efficiency of related companies and promote the further development of related companies.

3. CNC Turning

The application of this method in the production and processing of mechanical products mainly involves the processing of some rotary parts or rod parts. However, when this method is applied to the processing of mechanical parts, there are only plane forms and some limitations. Therefore, relevant personnel is required to configure according to the characteristics of the parts themselves and use CNC turning process to machine the parts.

The Future Trend of CNC Technology in Mold Machinery Manufacturing

– High efficiency

The efficient construction process is a very critical link in the development of CNC technology. To achieve efficient construction, it is necessary to ensure high-speed cutting of CNC machine tools, so as to reduce the probability of vibration of CNC machine tools and the probability of deformation during the machining of mechanical products. At the same time, it is necessary to strengthen the chip removal function of machine tools and the machining accuracy and quality of mechanical mold surfaces. In addition, it can also promote mechanical products to enter the mold processing link, instead of finishing this link, so as to improve the processing efficiency of mechanical mold manufacturing.

– Flexibility

Now the development process of flexible development and manufacturing of numerical control processing technology occupies the core position, and flexible development strengthens the development of numerical control processing technology, which can facilitate the flexible processing of mechanical parts, enable relevant operators to more intuitively feel the operation of the machine tool, and also enable relevant operators to more easily re compile and reorganize the machine tool operation program and system, So as to improve the production efficiency and quality of mechanical products.

– High accuracy

In order to improve the processing technology level of the CNC machine, the relevant technicians must fully and strictly control it, so as to ensure that the geometric and processing accuracy of the CNC machine is high, and at the same time, avoid undesirable phenomena in the processing process to the maximum extent, so as to improve the processing accuracy of the parts of the CNC machine tool.

– Intelligence

With the progress and development of the times, intelligent technologies and concepts have penetrated into all walks of life in China. In the future development of CNC machining technology, intelligent production and processing have become an important part of its future development, which can greatly reduce the labor intensity of workers in related industries, and reduce the working efficiency of the equipment itself, so as to ensure the processing quality of mechanical products.