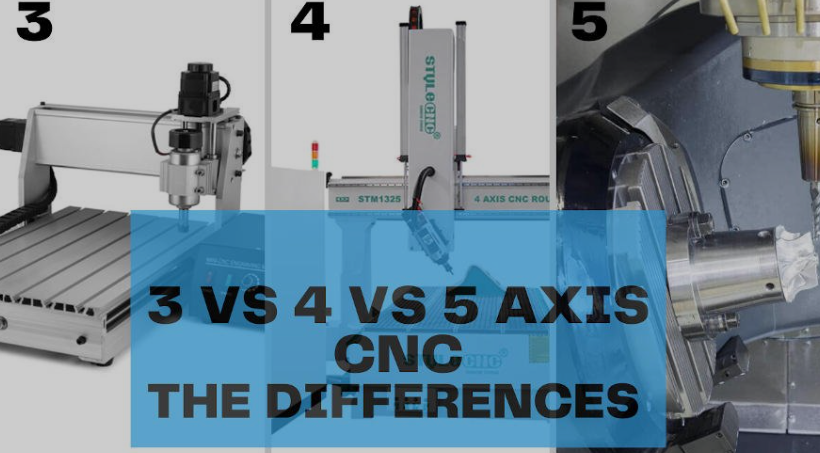

Basic knowledge of the different numbers of axes (3-axis, 4-axis, and 5-axis) is crucial when selecting a multi-axis CNC machining machine to suit the needs of a specific project. This article will cover the basics of multi-axis CNC machining and compare the features and benefits of 3-axis, 4-axis, and 5-axis CNC machining to help you make the right choice.

Definition of 3-axis, 4-axis and 5-axis

When describing multi-axis CNC machining, the commonly used coordinate system is the Cartesian coordinate system based on the X, Y, and Z axes. Here is a simple table to differentiate coordinate systems and axial movement for 3-axis, 4-axis, and 5-axis machines:

| Number of Axes | Coordinate System | Axial Movement |

| 3-axis | XYZ | Linear movement along the X, Y, and Z axes for cutting, drilling, milling, and more. |

| 4-axis | XYZA | In addition to the linear movement of the X, Y and Z axes, the rotation of the A axis can also be used to perform rotary machining in any direction of the part, such as milling of inclined surfaces. |

| 5-axis | XYZAB | Linear movement and rotation along the X, Y, Z, A and B axes, with the addition of rotation in the B axis, enables the machine tool to perform full range of multi-axis machining on parts with complex geometries. |

What do the X, Y, Z, A, and B axes represent?

When it comes to axes in CNC machining, common axes include X, Y, Z, A and B axes. They represent the movement or rotation of the machine tool in different directions. Through the combined movement or rotation of these axes, CNC machines can precisely position and machine workpieces in multiple directions. Different combinations of axes provide different machining capabilities and flexibility, enabling the machine tool to handle more complex geometries and achieve higher machining accuracy.

-X axis: The X axis usually represents the horizontal direction of the machine tool and moves along the left and right of the workpiece. In CNC machining, the X axis usually corresponds to lateral movement.

-Y axis: The Y axis usually represents the vertical direction of the machine tool and moves up and down along the workpiece. In CNC machining, the Y axis usually corresponds to the longitudinal movement.

-Z axis: The Z axis usually represents the depth direction of the machine tool and moves forward and backward along the workpiece. In CNC machining, the Z axis usually corresponds to the depth motion and is used to control the lowering and lifting of the tool.

-A axis: The A axis represents the axis of rotation of the machine tool, which allows the tool or workpiece to be rotated on a horizontal plane. The movement of the A axis is usually used to realize the machining of parts at different angles.

-B-axis: The B-axis represents the axis of rotation of the machine tool, which allows the tool or workpiece to be rotated in a vertical plane. The movement of the B axis is usually used to realize the processing of parts at different angles.

Key Differences Between 3-, 4-, and 5-Axis CNC Machining

There are differences in the movement range, precision and application fields of CNC machining with different axes.

| Number of Axes | Main Feature | Range of Movement | Precision | Surface Quality | Position Accuracy | Repeatability | Industry Manufacturing Example | Processing Accuracy |

| 3-axis | X, Y and Z axes | Machining of flat and simple 3D parts | ±0.01mm | Ra 0.8μm | ±0.005mm | ±0.003mm | Body panel cutting and milling operations in automotive manufacturing | ±0.02° |

| 4-axis | X, Y, Z and A axes | In addition to the 3-axis range of movement, the rotation of the A-axis makes it possible to perform rotational machining in any direction of the part | ±0.005mm | Ra 0.4μm | ±0.003mm | ±0.002mm | Manufacturing of complex aircraft engine housings in the aerospace sector, with precise milling and drilling operations at different angles | ±0.01° |

| 5-axis | X, Y, Z, A and B axes | In addition to the 4-axis range of movement, the rotation of the B-axis increases the flexibility of the machine tool, enabling a full range of multi-axis machining | ±0.003mm | Ra 0.2μm | ±0.002mm | ±0.001mm | Fabrication of complex orthopedic implants in medical device manufacturing with precise machining on multiple sides to meet specific anatomical requirements | ±0.005° |

Choice between 3-axis, 4-axis and 5-axis CNC machining

Choosing the right number of milling axes depends on the complexity of the part, machining requirements, budget, and productivity. When choosing between 3-axis, 4-axis, or 5-axis milling, there is no one-size-fits-all answer as to which is better, it depends on the specific application needs and the complexity of the part. It is necessary to comprehensively consider the complexity of parts, processing efficiency requirements, and budget constraints, and select the most suitable number of axes and machine types.

3-axis milling is suitable for flat and simple three-dimensional parts processing, relatively low cost, more common and widely used, suitable for processing parts with larger dimensions, and relatively fast manufacturing speed.

In addition to 3-axis movement, 4-axis milling also has A-axis rotation. It is suitable for complex parts that require inclined surface processing or cutting at specific angles. It is expensive and inferior to 5-axis milling. Manufacturing is fast, second to 5-axis milling. Rotation on one axis is allowed, and only one-shot processing of planar angle features is possible.

In addition to the movement capability of 4-axis, 5-axis milling also increases the rotation of B-axis. It is suitable for parts with complex geometry and curved surface. It is expensive. If the project requires high processing time and productivity, the shortest time is the most Complex shapes, the fastest to manufacture.

Common Makes and Models for 3-, 4-, and 5-Axis CNC Machining

1. Common brands and models in 3-axis CNC machining include:

-Haas VF-2: The VF-2 model from Haas Automation is a widely used 3-axis CNC milling machine for the machining of small to medium workpieces. It has the characteristics of high-speed cutting ability, high precision, easy operation and high reliability.

-Fanuc Robodrill α-D21MiA5: Fanuc’s Robodrill α-D21MiA5 is a compact 3-axis CNC milling machine for high-speed and high-precision machining. It features fast processing speed, high rigidity and stability, and flexible automation capabilities.

2. Common brands and models in 4-axis CNC machining include:

-Mazak VTC-300C: Mazak’s VTC-300C is a CNC milling machine with a 4-axis rotary table, suitable for complex-shaped workpiece machining. It has the characteristics of high-speed cutting ability, multi-functional processing, high precision and stability.

– DMG Mori DMU 50: DMG Mori’s DMU 50 is a CNC milling machine with a 4-axis rotary table for multi-angle machining. It has the characteristics of high precision, high rigidity, strong automation ability and various processing functions.

3. Common brands and models in 5-axis CNC machining include:

-Haas UMC-750: Haas Automation’s UMC-750 is a CNC milling machine with a 5-axis rotary table for complex shapes and multi-angle machining. It has the characteristics of high speed, high precision, good rigidity and strong stability.

-Okuma MU-4000V: Okuma’s MU-4000V is a CNC milling machine with a 5-axis rotary table for high-precision and high-efficiency machining. It has the characteristics of high-speed cutting ability, multi-functional processing, strong automation ability, and excellent rigidity.