Why Can’t Aluminum Die Casting Be T6 Heat Treated? | Diecasting-mould

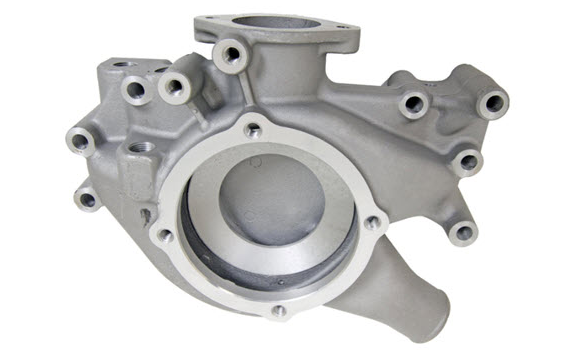

The usage of aluminum alloy die-casting is continuously rising with the development of social economy, and aluminum alloy die-casting itself is a kind of pressure-casting parts. In this article, we introduce T6 heat treatment for aluminum and detail why can’t aluminum die casting be heat treated with T6.

What Is T6 Heat Treatment For Aluminum & Why Can’t Aluminum Die Casting Be T6 Heat Treated

T6 treatment of aluminum alloy casting is solution treatment + artificial aging treatment heating – heat preservation – quenching – aging.

In general, T5/T6 treatment is not allowed for die casting products, because there are always blowholes in die casting, which can not be solved. It is just the size and location problem. During heat treatment, the blowholes inside aluminum alloy die casting will expand. If high speed and high pressure common die casting process is used for production, there must be a lot of blowholes under the surface of casting. After T6 heat treatment, the small pores under the surface of the casting expand and become big pores, forming bubbles on the surface of die casting.

All aluminum alloy die-casting that needs heat treatment should be produced by “slow die-casting process”. Meanwhile, gas generation and involvement should be avoided as far as possible. The aluminum alloy die-casting that needs heat treatment has strict control requirements on the die-casting process, which can not be produced casually.

So, can aluminum alloy die-casting be heat-treated? All aluminum alloy die-casting that wants to undergo heat treatment must be produced by the “slow die-casting process”. At the same time, the raw materials must be degassed, and gas generation and involvement must be avoided during production. However, in this highly competitive production environment, few manufacturers can truly meet the slow die casting process.

Aluminum Die Casting Heat Treatment

The heat treatment process of aluminum alloy die casting can be divided into annealing treatment, solution treatment, aging treatment, cold and hot cycle treatment and so on. Of course, different heat treatment methods can also effectively improve the processing performance, making the size of the stability.

– Annealing Treatment: The process of heating the aluminum alloy casting to a higher temperature, generally about 300 ℃, holding for a certain period of time and cooling it to room temperature with the furnace is called annealing. During the annealing process, the solid solution decomposes and the second phase particles gather, which can eliminate the internal stress of the casting, stabilize the size of the casting, reduce the deformation of the investment die casting aluminum parts and increase the plasticity of the casting.

– Solution Treatment: The casting is heated to a temperature as high as possible, close to the melting point of eutectic, maintained at this temperature for a long enough time, and then cooled rapidly to make the strengthening components dissolve to a greater extent. This high temperature state is fixed and stored to room temperature. This process is called solution treatment. Solution treatment can improve the strength and plasticity of the casting, improve the corrosion resistance of the alloy, and effectively prolong its service life.

– Aging Treatment: The casting after solution treatment is heated to a certain temperature, kept for a certain period of time, then discharged from the furnace, and slowly cooled to room temperature in the air. Aging treatment can significantly reduce the strength and improve the plasticity of the alloy. So that the application of the product is more extensive, and the performance is more stable.

– Cold And Hot Cycle Treatment: After cold and hot cycle treatment, the solid solution lattice shrinks and expands due to repeated heating and cooling, so that the lattice of each phase has a little displacement, making the second phase particles in a more stable state, so as to improve the dimensional stability of the casting, which is suitable for the manufacture of precision parts.

– Cold Treatment: The aluminum alloy has no tendency of brittle fracture at low temperature. With the decrease of temperature, the mechanical properties have some changes, the strength has been improved, but the plasticity has been reduced very little. Therefore, sometimes in order to reduce or eliminate the internal stress of the casting, the casting or quenched casting can be cooled to – 50 ℃, – 70 ℃ or lower temperature for 2-3 hours, Then it is heated to room temperature in air or hot water, or it is followed by artificial aging. This process is called cold treatment.

There are pores in the aluminum alloy die-casting, and the reasons are:

1. The direction of metal flow is incorrect, and it will have a frontal impact with the casting cavity, generate eddy currents, surround the air, and produce bubbles in the direction;

2. The inner gate is too small, and the metal flow rate is too large. Before the air is removed, the vent is blocked prematurely, leaving the gas in the casting;

3. The cavity is too deep and it is difficult to ventilate and exhaust;

4. The exhaust system design is unreasonable and it is difficult to exhaust.