Transfer molding is an important manufacturing process used to produce high-precision molded components from thermosetting materials. Let’s take a look at the basics of transfer molding, including the process, advantages, and differences between transfer molding and compression molding.

What Is Transfer Molding? - Process of Transfer Molding

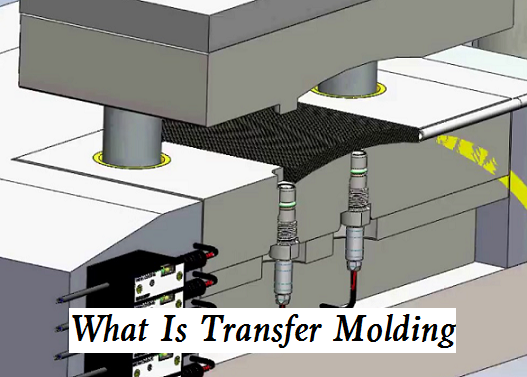

Transfer molding is a manufacturing process used to produce molded components from thermosetting materials. The process involves the transfer of a precisely measured amount of molten material, also known as the charge, from a separate chamber called a transfer pot, into closed molds placed in a molding press. The molten material is conveyed to the molds under high pressure through channels called runners and gates into the closed cavity. The transfer molding process is used to manufacture complex components with tight tolerances and intricate geometries. It is particularly well-suited to the production of small components, where consistency and precision are essential, such as those used in the automotive, aerospace, and electronics industries.

The process of transfer molding typically involves the following steps:

– Preheating: The molds are preheated to a specific temperature to prepare them for molding.

– Mixing: The thermosetting material is mixed with any necessary additives, such as colorants or reinforcements, in a separate mixing chamber.

– Charging: The mixed material is then transferred to the transfer pot, where it is brought to the appropriate temperature and pressure.

– Injection: The molten material is then injected into the molds under high pressure through runners and gates, filling the cavity and taking the shape of the mold.

– Curing: The mold is then held under pressure to allow the material to cure and harden, creating the finished component. The curing process typically involves heating the material to trigger a chemical reaction that causes it to solidify.

– Demolding: Once the component has fully cured, the mold is opened, and the finished component is removed.

Advantages of Transfer Molding

The process is also capable of producing components with low porosity and high mechanical strength, several advantages over other molding processes making it an attractive option for many industries.

– Improved precision: Transfer molding is capable of producing components with excellent precision and tight tolerances, making it ideal for the manufacturing of complex and intricate parts.

– High strength: The high pressure and temperature used in transfer molding combine to produce parts with superior mechanical strength, durability, and resistance to wear and tear, making them ideal for use in demanding environments.

– Consistency: The ability to precisely control the amount and distribution of material in the mold, coupled with the closed molding process, leads to greater consistency in the quality of the finished parts.

– Reduced waste: The precise control of material distribution in transfer molding helps reduce waste and minimize the environmental impact of the process.

– Design flexibility: The process can accommodate a wide range of component designs and sizes, making it a versatile option for manufacturers.

– Automated production: Transfer molding can be easily automated, which helps to reduce costs, improve efficiency, and achieve consistent quality.

– Reduced labor cost: Transfer molding requires less labor compared to other molding processes such as compression molding, making it more cost-effective for high-volume production.

– Faster cycle times: Transfer molding typically has shorter cycle times than compression molding, allowing for faster production runs and reduced lead times for the finished product.

Difference Between Transfer Molding and Compression Molding

Transfer molding and compression molding are both widely used manufacturing processes for thermosetting materials. While both processes share some similarities, there are also key differences between them.

Transfer molding is a molding process in which a separate chamber, called the transfer pot, is used to convey a precisely measured amount of molten material under high pressure through channels called runners and gates and into the closed cavity or cavities of a mold. The charge is a pre-measured amount of uncured rubber that is then conveyed through an uncured flow path via a plunger. The mold uses heat and pressure to cure the thermosetting material, producing a finished component. Compression molding, on the other hand, involves directly placing an uncured material in a heated mold cavity before applying heat and pressure to cure the material. The mold is closed, and the material is squeezed or compressed to conform it to the shape of the cavity.

Advantages of Transfer Molding over Compression Molding:

– Greater precision and complexity: Transfer molding is more precise, capable of producing more intricate geometries, and precise dimensions, making it ideal for the manufacturing of complex components such as micro-electronic components.

– Higher production volumes: Transfer molding offers a significant advantage in terms of higher production volumes and throughput. The production rates are typically faster than those of compression molding.

– Higher material utilization: Transfer molding uses the material more efficiently than compression molding, ensuring minimal material waste, and reducing the cost of raw materials.

– Reduced post-processing: Components produced through transfer molding typically require less post-processing than those produced through compression molding, which can lead to lower costs.

– Better consistency and control: Transfer molding offers greater control over the molding and curing process, resulting in higher consistency in the quality of the finished component.

Advantages of Compression Molding over Transfer Molding:

– Lower tooling costs: Compression molding requires less complex molds and tooling than transfer molding, leading to lower tooling costs.

– Simpler process: Compression molding is relatively simpler than transfer molding, making it easier to learn and implement in a manufacturing environment.

– Lower production costs: Compression molding requires less equipment, fewer raw materials, and lower energy consumption than transfer molding, reducing production costs.

– Better material options: Compression molding has no restriction on mold flow, allowing it to be used with a wider range of materials and composites than Transfer molding.