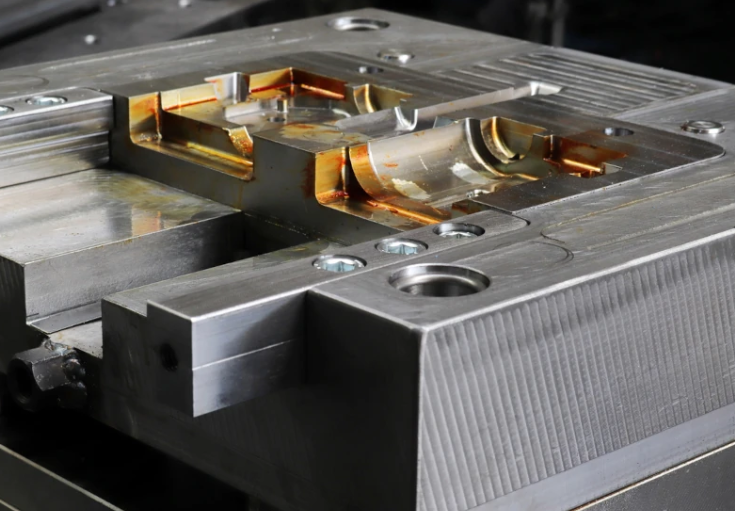

Mold manufacturing technology has rapidly developed and become an important component of modern manufacturing technology. Technologies such as mold CAD/CAM, mold laser rapid forming technology, mold precision forming technology, mold ultra precision machining technology, mold design using finite element method and boundary element method for dynamic simulation of fluid flow, cooling and heat transfer processes, mold CIMS technology, mold DNM technology that has been developed, and NC technology almost cover all modern manufacturing technologies. Modern mold manufacturing technology is developing towards accelerating information driven, improving manufacturing flexibility, agile manufacturing and system integration.

High-speed milling: Third-generation mold making technology

Highspeed milling machining not only has the advantages of high machining speed and good machining accuracy and surface quality but also has lower temperature rise (the workpiece is only heated up by 3°C) and smaller heat deformation during machining compared with traditional cutting machining. Therefore, it is suitable for machining temperature sensitive materials (such as magnesium alloys). It can also be used for machining thin-walled and low-rigidity parts due to smaller cutting force. A reasonable selection of tools and cutting amount can realize the machining of hard materials (HRC60). Therefore, high-speed milling machining technology is still a hot topic. It has developed towards higher agility, intelligence, and integration and become the third-generation die casting mold making technology.

Electric Discharge Machining “Green” Product Technology

In terms of electric machines from abroad, in terms of performance, process indicators, intelligence, automation, they have reached a very high level. The new trends abroad are conducting research and development of electric discharge machining technology (electrical discharge wire cutting technology). This new technology replaces the traditional use of shaping electrodes for cavity machining. It uses a simple rotating tubular electrode for three-dimensional or two-dimensional contour machining (like CNC milling). Therefore, there is no longer a need to manufacture complex shaping electrodes, which is a major development in the field of electric discharge machining.

Recently, Mitsubishi introduced the EDSCAN8E electric discharge wire cutting machine with new progress. The system can automatically compensate for electrode wear, develop dedicated CAM systems for the machine on Windows 95, which can be linked with AutoCAD and other general CAD systems. It can also perform line precision measurement to ensure high precision machining. To confirm whether there are any abnormalities or defects in the machined shape, the CAM system can also simulate machining.

With the progress of electric discharge machining technology, electric discharge machining safety protection technology is also receiving more attention. Many electric machining centers have considered safety protection technology. Currently, the European Community has stipulated that machines without the “CE” mark cannot enter the European common market. International markets are also increasingly focusing on safety protection requirements.

The main problem of electric discharge machining centers now is radiation interference, because it has a greater impact on safety and the environment. Under increasing international market emphasis on “green” products, electric discharge machining center “green” product technology will be an important issue to address in the future, as electric discharge machining centers are the leading equipment for mold manufacturing.

New Generation Mold CAD/CAM Software Technology

Currently, mold software developed by schools, research institutes in countries such as the UK, US, Germany and some of China’s research institutes have characteristics such as intelligent, integrated mold manufacturability evaluation. The new generation of mold software should be established based on a large amount of knowledge summarized from practical experience in mold design. This knowledge is scientifically and systematically organized and stored in an engineering knowledge base and can be conveniently accessed by molds. With intelligent software support, mold CAD will no longer mimic traditional design and calculation methods, but guide advanced design theories to fully utilize the rich knowledge and successful experience of experts in this field. The design results will certainly have rationality and advanced nature.

The new generation of mold software designs mold structures with stereoscopic thinking and intuitive perception. The generated 3D structural information can facilitate mold manufacturability evaluation, numerical control machining, which requires the mold software to achieve a relatively high level of parameterization, molding process simulation, NC machining process simulation and information exchange, organization and management. To measure the level of software integration, it is not only necessary to see if the functional modules are complete, but also to see if these functional modules share the same data model and form a dynamic global database in a unified manner to realize integrated management and sharing of information to support the entire process of mold design, manufacturing, assembly, inspection and production.

The function of mold manufacturability evaluation in the new generation of mold software is very important. It needs to screen multiple schemes and evaluate the rationality and economy of the mold design process to provide modification guidelines for mold designers. The main contents of mold manufacturability evaluation include mold design and manufacturing cost estimation, mold assembly evaluation, mold part manufacturing process evaluation, mold structure and forming performance evaluation.

The new software should also have assembly oriented functions, because the functions of molds can only be embodied through their assembly structure. After adopting assembly oriented design methods, mold assembly is no longer a simple attachment of individual parts, but the data structure can describe mold functions and define the interrelationship and assembly features between mold components, realizing component association to effectively ensure mold quality.

Advanced Rapid Mold Manufacturing Technology

Laser rapid prototyping technology (RPM) has developed rapidly in China and reached the international level, and is gradually being commercialized. The main commercialized rapid forming processes in the world include SLA (stereolithography), LOM (laminated object manufacturing), SLS (selective laser sintering), and 3D printing.

Tsinghua University was the first to introduce SLA250 equipment and technology (stereolithography or light curing of photosensitive resins) from the US and carry out development research. After several improvements, it launched the “M-RPMS-type multi functional rapid prototyping system” (with laminated entity manufacturing – SSM and melted extrusion molding – MEM), which owns world’s only two kinds of rapid forming process systems (national patents) and has good performance and price ratio.

Multi point forming technology without molds uses a highly adjustable punch group instead of conventional molds for sheet metal surface forming, which is another advanced manufacturing technology. The moldless multi point forming system uses CAD/ CAM / CAT technology as its main means to achieve three dimensional surface automatic forming rapidly and economically. Jilin University undertook a key state S&T project on moldless forming technology and independently designed and manufactured a moldless multi-point forming equipment with an international leading level.

In terms of theoretical research and practical application, China’s level in this area is leading compared to Massachusetts Institute of Technology, University of Tokyo and okyo Institute of Technology in Japan. It is currently developing towards commercial application and promotion.

Resin die casting molds were successfully applied for the first time in domestic car trial production. One of the Chrysler Mold Manufacturing Co., Ltd. designed and manufactured 12 sets of resin molds for the new trial production of the mini cooper sedan facelift, including large and complex interior and exterior coverage parts such as luggage compartment, engine hood, front and rear wings made of drawing molds. The main features are that the mold surfaces are based on the primary model machined by CAD/CAM, high strength resins from Switzerland Rheinmettal are adopted for die casting molding, the gaps between convex and concave molds are accurately controlled by imported special wax sheets, mold dimensions, and accuracy are high, the production cycle can be shortened by half to two thirds, and manufacturing costs can be saved by about 10 million yuan (for the 12 sets of molds). This has opened up a new way for trial small batch production of domestic cars, being the first in China. Experts from Switzerland Rheinmettal believe that the level can reach that of the 1990s internationally.

Insitu Mold Inspection Technology

With the development of precision molds, measurement requirements are getting higher and higher. Coordinate measuring machines have rarely been used in production workshops due to environmental limitations. The new generation of coordinate measuring machines has temperature compensation and uses vibration-resistant materials. They have improved dust prevention measures and adaptability and reliability, making it convenient to install and use them in workshops to realize the characteristics of in situ measurement.

Mirror Polishing Mold Surface Engineering Technology

Mold polishing technology is an important part of mold surface engineering. Currently, domestic mold polishing equipment, polishing tools and processes can meet the needs of polishing to Ra0.05μm. While polishing to Ra0.025μm mirror surface polishing equipment, tools, and process is still in the exploration stage as large scale production of mirror injection molds is applied. As domestic polishing technology and materials still have certain problems, a large part of camera lens injection molds, CD, VCD optical disks and tools with high transparency requirements still rely on imports.

It is worth noting that mold surface polishing is not only affected by polishing equipment, process and technology but also affected by the mirror degree of mold materials, which has not attracted enough attention. That is to say, polishing itself is restricted by mold materials. For example, when a #45 carbon steel mold is polished to Ra0.2μm, obvious defects can be seen with the naked eye, and continuing to polish can only increase brightness while roughness can no longer be improved.