Tensile stress refers to the internal stress induced in a material when it is pulled or stretched. It is the opposite of compressive stress. In this blog, we will break down what tensile stress is in the context of strength of materials and provide examples on how to calculate it.

Tensile Stress Definition – What is Tensile Stress?

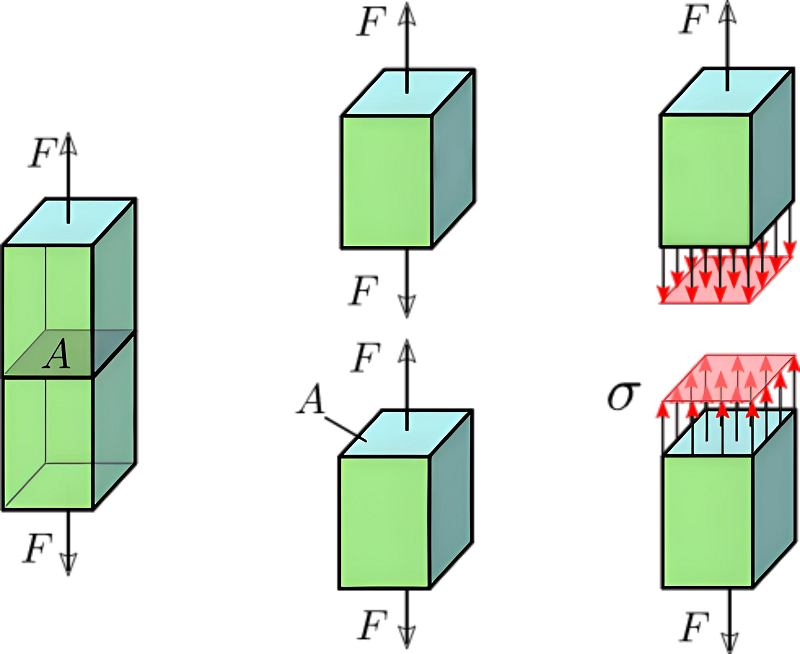

Tensile stress occurs when a force is applied to an object in such a way that it stretches or elongates the material. For example, if an object is hung from a ceiling and a downward force is applied, the object experiences tensile stress, which is defined as the force divided by the cross-sectional area of the object. This force is transmitted throughout the entire object, and as the object stretches, the distance it elongates is measured as the change in length. The magnitude of tensile stress present in the object can be calculated using the formula: tensile stress equals the applied force divided by the area over which the force acts. If the tensile stress becomes high enough, the object can eventually fracture. This concept plays a central role in material science and engineering, as the ability of a material to withstand tensile stress determines how much load it can safely support when subjected to stretching or pulling forces.

Tensile Stress Symbol:

σt, where σ represents stress and the subscript t indicates the tensile direction. Sigma (σ) is a Greek letter that serves as a universal symbol for stress in mechanics, representing the internal forces acting on a unit area. The subscript letter t is an abbreviation for “tensile”, which clearly indicates that the stress is tensile stress. This naming convention is concise and in line with disciplinary standards, making it easy for academic exchange and engineering applications.

Tensile Stress Unit:

Common units of tensile stress include Pascal (Pa), Megapascal (MPa), and kilogram-force per square millimeter (kgf/mm). 1 MPa equals 1000 kilopascals, and 1 kgf/mm² equals 0.0981 MPa. In engineering, MPa is often used as the unit of tensile stress, expressed as MPa.

Tensile Stress Diagram:

Tensile Stress Area:

The tensile stress area is the specific cross-sectional area of a material over which an external force is applied during tension. In tensile stress calculations, this area is a key factor because it determines how the applied force is distributed within the material. For instance, when testing a specimen with a circular cross-section, the tensile stress area is calculated as π times the square of the radius. Accurate measurement of this area is vital, as any error can affect the calculation of tensile stress. The tensile stress area allows for a standardized way to compare different materials’ abilities to withstand stretching forces, and it is consistently used in engineering design, material testing, and structural analysis to ensure reliable and safe performance.

Tensile Stress Formula & Calculation

Tensile stress calculation methods are an important tool for evaluating the stress conditions of materials. They assist in analyzing the mechanical properties of materials during tension.

The tensile stress calculation formula is σ = F/A,

Where:

- σ represents tensile stress

- F refers to the external force acting on the material and is a key factor in the Tensile Stress calculation.

- A is the cross-sectional area over which the force is distributed

Accurate measurement of both the applied force and the cross-sectional area is necessary for reliable results, with force typically measured in Newtons and area in square meters to maintain consistent units. During tensile testing, force and deformation data are recorded to determine how a material responds under tension, and this method is applicable across various materials, including metals, plastics, rubber, and composites, each with distinct considerations due to their mechanical properties. The tensile stress calculation not only helps evaluate a material’s ability to withstand loads but also guides material selection and engineering design, ensuring that the chosen material can perform safely under expected operating conditions.

How To Calculate Tensile Stress

Measure the applied force, find the perpendicular cross-sectional area, and divide the force by the area to obtain the tensile stress value. Check this value against material limits to ensure it does not fail.

- Step 1: Identify the forces applied on the material that cause the tensile stress. This would usually be a force that pulls or stretches the material from both ends. Measure the magnitude of this applied force (F).

- Step 2: Determine the cross-sectional area (A) perpendicular to the applied force. This can be found by measuring width and thickness and multiplying them. For circular cross-sections, use the formula A = πr2.

- Step 3: Use the formula for tensile stress:

σ = F /A

σ – Tensile stress (Pa or N/m2)

F – Applied force (N)

A – Cross-sectional area (m2)

- Step 4: Substitute the values of force and area into the formula to calculate the tensile stress.

- Step 5: The unit for tensile stress is Pascals (Pa) or Newtons per square meter (N/m2). Convert units if necessary.

- Step 6: Compare the calculated tensile stress to the ultimate tensile strength of the material. The tensile stress should be lower for safe design.

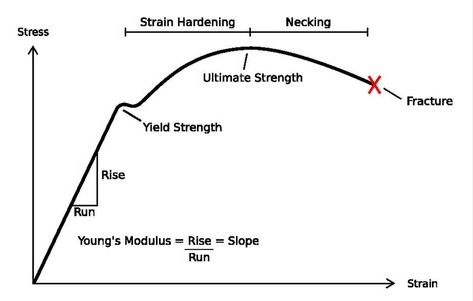

What Can Be Calculated When Tensile Stress Acts on a Material

When a tensile stress is applied, you can calculate the resulting elongation, strains, strength limits, stiffness, and factor of safety for the material based on its mechanical properties. This helps determine if the material will yield, deform, or fracture under the given loading conditions.

- – Elongation/Extension

The increase in length of the material due to the applied tensile force. This depends on the elastic modulus of the material.

- – Strain

The ratio of elongation to the original length. This is a dimensionless quantity.

- – Poisson’s Ratio

The ratio of transverse contraction strain to longitudinal extension strain in the direction of stretching force.

- – Yield Strength

The stress at which material starts deforming plastically.

- -Ultimate Tensile Strength

The maximum stress the material can withstand before fracture.

- -Modulus of Elasticity

Ratio of the stress to strain in the elastic deformation region. Indicates stiffness of the material.

- -Fracture Point

The stress level at which fracture occurs.

- -Safety Factor

Ratio of fracture stress to working stress. Indicates how much stronger the material is than the expected load.

Tensile Stress Area of Bolt Formula & Calculation

The tensile stress area of a bolt refers to the effective cross-sectional area where the tensile load is carried, usually located at the threaded portion of the bolt. This area is less than the nominal (full) cross-sectional area because the threads reduce the amount of material available to bear the load. For standard metric bolts, the tensile stress area can be calculated using a specific formula:

Tensile Stress Area Formula for Metric Bolts:

𝐴𝑠 = 𝜋/4 (𝑑2+𝑑3)2 / 2

Where:

- 𝑑2 = pitch diameter of the thread

- 𝑑3 = minor diameter of the thread

In practice, engineers often refer to standardized tables to find the tensile stress area for a given bolt size, such as those provided by ISO or ANSI standards. The correct tensile stress area is essential for calculating the tensile strength and ensuring that the bolt can safely support the required load without failure. For example, an M10 coarse thread bolt has a nominal diameter of 10 mm, but its tensile stress area is approximately 58 mm², which is less than the area based on the full diameter due to the thread geometry. Accurate use of the tensile stress area is crucial in bolt selection, structural calculations, and safety assessments in mechanical and civil engineering applications.

Allowable (Permissible) Tensile Stress Formula & Calculation

Allowable or permissible tensile stress is the maximum stress that a material can safely withstand under service conditions, typically set below the ultimate strength to provide a safety margin.

To determine the allowable tensile stress, a safety factor (𝑆𝐹) is applied to the ultimate tensile strength (𝜎𝑢𝑙𝑡):

Calculation Formula: σallowable = 𝑆𝐹 / 𝜎𝑢𝑙𝑡

The safety factor reflects the expected loading conditions, uncertainties in material properties, and other considerations.

Example Application:

When calculating tensile stress in different materials, it is important to consider the specific properties of the material, such as strength grade in metals or elastic properties in plastics. The accuracy of force and area measurements is essential for reliable results. Material tensile testing provides the necessary data for these calculations.

Ultimate Maximum Tensile Stress Formula & Calculation

Ultimate maximum tensile stress, also known as ultimate tensile strength, is the highest stress a material can withstand when being stretched or pulled before failing.

Calculation Method:

The formula for ultimate tensile strength is: 𝜎𝑢𝑙𝑡 = 𝐹𝑚𝑎𝑥 / 𝐴

where:

- 𝜎𝑢𝑙𝑡 is the ultimate tensile strength,

- 𝐹𝑚𝑎𝑥 is the maximum force the material can sustain before failure,

- 𝐴 is the cross-sectional area.

This value represents the maximum force per unit area that the material can handle without breaking. For example, the maximum tensile strength of concrete is 2×106 N/m², while its compressive strength is much higher.

Tensile Stress Example – What Are the Examples of Tensile Stress?

- – Tension in a rope

When you hang an object from a rope, the suspended weight puts the rope under tensile stress. The rope elongates slightly under the applied tensile force.

- – Pulling on a rubber band

Stretching a rubber band causes tensile stress. The molecular chains in the rubber experience forces trying to separate them lengthwise.

- – Tightening bolts

Tightening nuts and bolts induces axial tensile stress in the bolt shank. This clamping force holds the parts together.

- – Loading a fishing line

Reeling in a big fish applies large tensile forces on the fishing line. This can cause the line to snap if the tensile strength is exceeded.

- – Tension in cables

Suspension cables in bridges carry the deck’s weight through axial tension forces. The cables are under constant tensile stress.

- – Loading machine parts

Gears, pulley belts, and other machine parts undergo tension when transmitting torque or power. The tensile stress must be below the yield strength.

- – Stretched springs

The coil of a stretched spring experiences tensile stress proportional to the displacement from its relaxed length.

- – Wire drawing

Pulling metal wire through a die reduces its diameter and subjects it to tensile stresses. This strengthens the wire.

- – Tension in fabrics

Fabrics experience tensile stresses when stretched or pulled. Clothing needs to withstand such stresses during wear.

How Does Tensile Stress Relate to Die Casting?

Controlling tensile stress through die design and process parameters is important in die casting to avoid hot tearing defects and achieve high-quality castings. Understanding how tensile stress develops guides the design.

- – During the die-casting process, the molten metal is injected into the mold under high pressure. This causes tensile stresses to develop in the solidifying casting.

- – If the tensile stresses exceed the material’s tensile strength, it can lead to hot tearing – cracks that form in the casting as it solidifies. These defects in the casting.

- – The location of holes, the thickness of walls, andthe geometry of the die casting affect how tensile stress develops. Sharp corners and thin sections tend to have higher tensile stresses.

- – Alloys used for die casting, like aluminum and zinc, have a relatively low tensile strength in the molten state. So minimizing tensile stresses is critical.

- -The cooling rate of the die also affects tensile stress. Faster cooling leads to higher thermal gradients and tensile stress. Slower cooling reduces this.

- – Tensile properties can be improved by heat treatment like solution treatment and aging after die casting. This relieves some residual stresses.

- -The design of the die casting has to balance the flowability of metal with minimizing tensile stress. Computer simulation is used to optimize this.