Lag screws are some of the toughest fasteners, these extremely sturdy fasteners are usually used to connect heavy lumber or other heavy materials that are bearing an intense load, they differ from normal wood self drilling or sheet metal screws. Have you ever wondered what lag screws are and how they fit into the world of fasteners. Let’s break it down in detail by talking about its meaning, if it same as lag bolt, purpose, applications, head types, sizes (head, diameter, lengths), pilot hole drill size chart, strength capacity, and more!

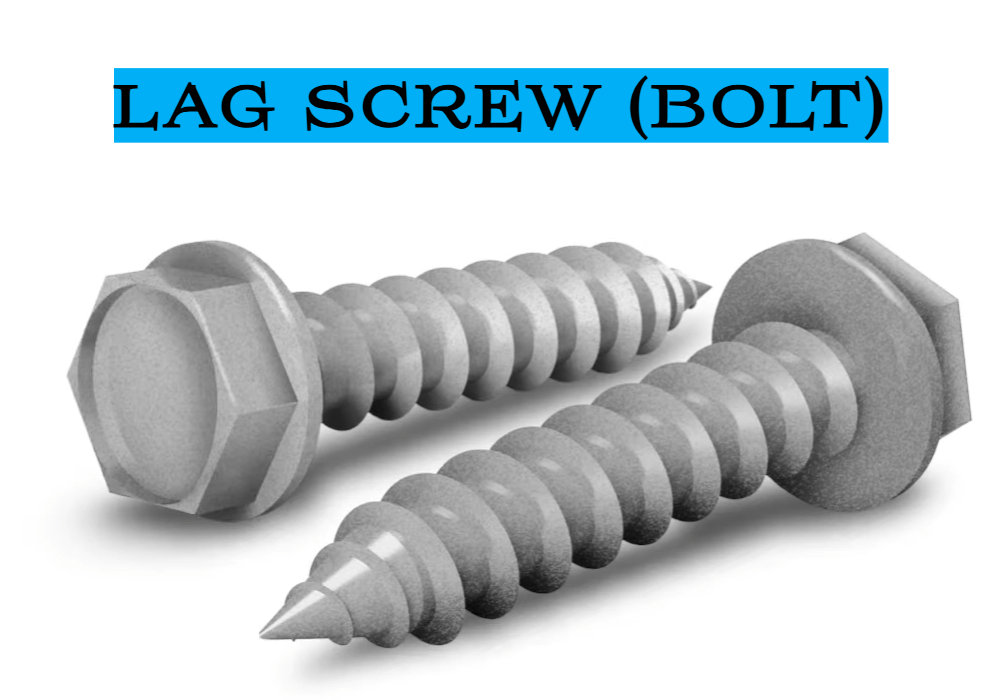

What are Lag Bolts?

Lag screws, also known as lag bolts, are heavy-duty fasteners designed for strong connections. These threaded components have a pointed end and varied head shapes, although they are usually hexagonal. What sets lag screws apart is their hexagonal heads. This design allows you to easily tighten them with a wrench or socket driver. This feature is especially handy in situations where you need to apply a lot of torque. Lag screws have a tapered pointed end that acts as a self-rilling pilot point. This design reduces the risk of splitting the material they are being driven into, which is essential in construction projects.

The hex lag screws also has some alternative names, as not everyone within our industry refers to this product as a hex flange lag screw, sometimes you may hear this fastener referred to as a wood screw, a hex wood screw, or a hex washer head wood screw.

Lag Screw Purpose – What the Benefits of Using Lag Screw?

You can expect to receive added benefits when using a hex flange lag screw as the built-in flange accomplishes three things:

- 1. It will resist wood pull through reducing the likelihood of a failed assembly

- 2. The built-in flange will also spread the clamp load over a wider area creating a tighter and more secure bond when fastening metal components to wood substrates

- 3. The built-in flange also replaces traditional hex lag screw and washer assemblies.

Other benefits of choosing a hex flange lag screw include the wide space thread which will prevent the screw from stripping out over time, and a 60 degree tapered point which allows for self-centering helps the hex flange lag screw remains straight as it’s driven into wood. However, it is important to keep in mind that this screw does require you to pre-drill a pilot hole before installation.

Lag Screw Materials – What Material To Make Lag Screw?

The construction of lag screws typically involves durable materials like steel, stainless steel, or galvanized steel. These materials help resist corrosion, making them suitable for both indoor and outdoor applications.

Lag Screw vs Lag Bolt, What are the Difference Between?

This might come as a surprise to many DIY fans, but like screws and bolts are essentially the same thing, and the correct term here is the lag screw, shouldn’t really call this fastener lag bolt as it doesn’t come with a nut/washer. Are lag bolts and lag screws the same? Lag screws and lag bolts refer to essentially the same type of threaded fastener. But why does the term lag bolt even exist? Well, it does look very much like a bolt, as the tip isn’t very sharp. Next, in contrast to most modern-day screws, the shank is relatively big, the threads don’t go all the way up to the head which again is not common for a screw and that’s exactly why you might mistake these screws with bolts. And since many bolts are sold without any nuts or washers in the package, it is even harder for the average person to figure out that they’re dealing with this screw. More importantly, while most screws are self-drilling the same can’t be said about bolts, we say most because lag screws are not self-drilling, they’re only self-tapping. Finally, their heads are hexagonal, you’ll have to tighten them with a wrench.

Lag Screw Applications – What is Lag Screw Used For?

Lag screws are incredibly sturdy, tough, reliable, and robust fasteners used mainly in heavy-duty applications. You might find lag screws in applications like building decks, retaining walls, tv mount, concrete, deck, metal studs, ledger board, or even installing overhead garage doors. If you’re working with heavy duty materials like Lumber, lag screws will be a great pick. They easily handle heavy loads in high pressure which tends to be problem for most regular wood screws. In construction, these fasteners are the go to choice for lumber. Thanks to the extended length compared to the average size screw slash bowl, they do an excellent job of holding large pieces of wood. Lag screws aren’t the best pick for metal though, originally these screws were manufactured to be used on Barrel Stave slash legs.

Lag Screw Strength & Load Capacity – Are Lag Screws Strong?

A lag screw can provide extended strength and load capacity over standard types of self drilling wood and metal screws, this is because of their longer and thicker structure, they are very effective in the joining of heavy timber and other structural elements in wood framing and pipe lagging.

- Tensile Strength: For steel lag screws, it can be a minimum of 60.000 psi [4]. Stainless steel can reach a minimum of 100.000 psi.

- Yield Strength: For steel lag screws, it can be a minimum of 57.000 psi.

- Shear Strength: Approximately 60% of the tensile strength. However, without a specific grade, determining shear or tensile strength is impossible without testing.

- Power Pro Structural Lag Screws: Some screws, like Power Pro, are designed as a substitute for standard lag screws and offer Grade 5 strength

- Load Capacity: The weight capacity of lag screw or bolt can vary. For example, a 1/4″ lag screw can hold up to 272 lbs. The pull-out force for a 5/16″ lag screw can range between 205-307 lbs. The American Wood Council (AWC) provides design guidelines for lag screw withdrawal resistance values

Lag Screw Pullout Strength Chart (Metric & Inches)

| Lag Screw Size (inches) | Lag Screw Size (mm) | Pullout Strength Softwood | Pullout Strength Hardwood | ||

|---|---|---|---|---|---|

| lbs | kg | lbs | kg | ||

| 1/4″ | 6 | 272 | 123 | 360 | 163 |

| 5/16″ | 8 | 310 | 141 | 400 | 181 |

| 3/8″ | 10 | 360 | 163 | 500 | 227 |

| 1/2″ | 12 | 420 | 191 | 600 | 272 |

| 5/8″ | 16 | 480 | 218 | 750 | 340 |

| 3/4″ | 20 | 540 | 245 | 900 | 408 |

Lag Screw Grade Chart

Like other fasteners, lag screws come in different grades, which indicate their material strength and suitability for various applications:

| Grade | Head Marking | Material Type | Tensile Strength (psi) | Typical Use |

|---|---|---|---|---|

| Grade 1 | None | Low Carbon Steel | ~60,000 | General wood |

| Grade 2 | None | Low/Med Carbon | ~74,000 | General wood |

| Grade 5 | 3 Radial Lines | Medium Carbon | ~120,000 | Structural/Heavy |

| Grade 8 | 6 Radial Lines | Alloy Steel | ~150,000 | Heavy Industrial |

| Stainless (304/316) | None | Stainless Steel | ~60,000 | Corrosive env. |

Lag Screw Size Chart (Diameter, Head, Length Dimenions)

Lag screw sizes refer to the diameter, length, and thread specifications, which determine their holding strength and suitable applications. Lag screws typically range in diameter from 1/4 inch up to 1/2 inch, with some larger sizes available for heavy-duty structural uses. Lengths typically start at 1 inch and can go up to 6 inches or longer, depending on the diameter. The size you choose should be based on the thickness of the materials being joined and the load requirements. Lag screws are measured by the shaft diameter (not including the threads) and the length from under the head to the tip of the screw.

Below we present the standard hex lag screw (bolt) size chart in metric (mm) and imperial (inches):

Imperial Lag Screw Size Chart (Inches)

| Basic Product Diameter | Threads Per Inch | Body/Shoulder Diameter Max | Body/Shoulder Diameter Min | Width Across Flats (Basic) | Width Across Flats (Max) | Width Across Flats (Min) | Width Across Corners (Max) | Width Across Corners (Min) | Head Height (Basic) | Head Height (Max) | Head Height (Min) | Shoulder Length (Min) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| #10 | 11 | 0.199 | 0.178 | 9/32 | 0.281 | 0.271 | 0.323 | 0.309 | 1/8 | 0.140 | 0.110 | 0.094 |

| 1/4 | 10 | 0.260 | 0.237 | 7/16 | 0.445 | 0.425 | 0.505 | 0.484 | 11/64 | 0.188 | 0.150 | 0.094 |

| 5/16 | 9 | 0.324 | 0.298 | 1/2 | 0.500 | 0.484 | 0.577 | 0.552 | 7/32 | 0.235 | 0.195 | 0.125 |

| 3/8 | 7 | 0.388 | 0.360 | 9/16 | 0.562 | 0.544 | 0.650 | 0.622 | 1/4 | 0.268 | 0.226 | 0.125 |

| 7/16 | 7 | 0.452 | 0.421 | 5/8 | 0.625 | 0.603 | 0.722 | 0.687 | 19/64 | 0.316 | 0.272 | 0.156 |

| 1/2 | 6 | 0.520 | 0.482 | 3/4 | 0.750 | 0.725 | 0.866 | 0.826 | 11/32 | 0.364 | 0.302 | 0.156 |

| 5/8 | 5 | 0.642 | 0.605 | 15/16 | 0.938 | 0.905 | 1.083 | 1.033 | 27/64 | 0.444 | 0.378 | 0.312 |

| 3/4 | 4-1/2 | 0.768 | 0.729 | 1-1/8 | 1.125 | 1.088 | 1.299 | 1.240 | 1/2 | 0.552 | 0.455 | 0.375 |

| 7/8 | 4 | 0.895 | 0.852 | 1-5/16 | 1.312 | 1.269 | 1.516 | 1.447 | 37/64 | 0.604 | 0.531 | 0.375 |

Metric Lag Screw Size Chart (MM)

| Lag Screw Dia. D | Body Diameter Ds | Width Across Flats S | Width Across Corners E | Head Height K | Wrenching Height K1 | ||||

|---|---|---|---|---|---|---|---|---|---|

| Max | Min | Max | Min | Max | Min | Max | Min | ||

| 5 | 5.48 4.52 | 8.00 | 7.64 | 9.24 | 8.63 | 3.9 | 3.1 | 2.4 | — |

| 6 | 6.48 5.52 | 10.00 | 9.64 | 11.55 | 10.89 | 4.4 | 3.6 | 2.8 | — |

| 8 | 8.58 7.42 | 13.00 | 12.57 | 15.01 | 14.20 | 5.7 | 4.9 | 3.7 | — |

| 10 | 10.58 9.42 | 16.00 | 15.57 | 18.48 | 17.59 | 6.9 | 5.9 | 4.5 | — |

| 12 | 12.70 11.30 | 18.00 | 17.57 | 20.78 | 19.85 | 8.0 | 7.0 | 5.2 | — |

| 16 | 16.70 15.30 | 24.00 | 23.16 | 27.71 | 26.17 | 10.8 | 9.3 | 7.0 | — |

| 20 | 20.84 19.16 | 30.00 | 29.16 | 34.64 | 32.95 | 13.4 | 11.6 | 8.8 | — |

| 24 | 24.84 23.16 | 36.00 | 35.00 | 41.57 | 39.55 | 15.9 | 14.1 | 10.5 | — |

| Thread Dimensions | Thread Dimensions | ||||||||

| Lag Screw Dia. D | Thread Pitch p | Flat at Root V | Depth of Thread T | Root Dia. D1 | Nominal Screw Dia. D | Thread Pitch p | Flat at Root V | Depth of Thread T | Root Dia. D1 |

| 5 | 2.3 | 1.0 | 0.9 | 3.2 | 12 | 4.2 | 1.8 | 1.6 | 8.7 |

| 6 | 2.5 | 1.1 | 1.0 | 4.0 | 16 | 5.1 | 2.2 | 2.0 | 12.0 |

| 8 | 2.8 | 1.2 | 1.1 | 5.8 | 20 | 5.6 | 2.4 | 2.2 | 15.6 |

| 10 | 3.6 | 1.6 | 1.4 | 7.2 | 24 | 7.3 | 3.1 | 2.8 | 18.1 |

Lag Screw Pilot Hole Size Chart

Pilot holes should be drilled for hex lag screws, this is recommended as a way to prevent the head from snapping when torque is applied in the tightening process. This step is critical when the lag screw or lag bolt has a larger diameter when determining. The correct diameter for the pilot hole it should be slightly smaller than the diameter of the screw, in the case of a 3/4 inch lag screw, a 1/2 inch pilot hole will need to be drilled prior to installation. Check out more pilot hole size for standard lag screws and bolts in the current market now on the below table:

Lag Screw Pilot Hole Drill Size Chart (Metric & Inches)

| Lag Screw Size (in) | Lag Screw Size (mm) | Soft Wood | Medium Wood | Hard Wood | |||

|---|---|---|---|---|---|---|---|

| Inch | mm | Inch | mm | Inch | mm | ||

| 1/4″ | 6 | 3/32″ | 2.4 | 5/32″ | 4.0 | 3/16″ | 4.8 |

| 5/16″ | 8 | 9/64″ | 3.6 | 3/16″ | 4.8 | 13/64″ | 5.2 |

| 3/8″ | 10 | 11/64″ | 4.4 | 15/64″ | 6.0 | 1/4″ | 6.4 |

| 1/2″ | 12 | 15/64″ | 6.0 | 5/16″ | 8.0 | 11/32″ | 8.8 |

| 5/8″ | 16 | 5/16″ | 8.0 | 13/32″ | 10.3 | 29/64″ | 11.5 |

| 3/4″ | 20 | 13/32″ | 10.3 | 1/2″ | 12.7 | 9/16″ | 14.3 |

Lag Screw Weight Chart – How Much Weight Can Lag Screws Hold?

Lag screw load or weight capacity depends on a few different factors pertaining to the fastener attributes and where it is installed weight capacity factors include the shaft length and the diameter as well as the material used to manufacture the screw the density of the specific type of wood where the screw is installed will also be a significant factor.

Check out the weight for standard lag screws and bolts on the below table:

Lag Screw Weight Chart (Metric & Inch)

| Length (in) | Length (mm) | #2 | #3 | #4 | #5 | #6 | #8 | #10 | #12 | 6 mm (1/4″) | 8 mm (5/16″) | 10 mm (3/8″) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/8″ | 3 | 0.40 | 0.55 | 0.70 | 1.1 | 1.4 | — | — | — | — | — | — |

| 3/16″ | 5 | 0.50 | 0.70 | 0.90 | 1.2 | 1.5 | 2.5 | 3.9 | — | — | — | — |

| 1/4″ | 6 | 0.60 | 0.80 | 1.00 | 1.4 | 1.7 | 2.8 | 4.3 | 5.6 | 8.5 | — | — |

| 5/16″ | 8 | 0.60 | 0.90 | 1.20 | 1.5 | 1.9 | 3.1 | 4.6 | 6.1 | 9.1 | 16.7 | — |

| 3/8″ | 10 | 0.70 | 0.90 | 1.30 | 1.7 | 2.1 | 3.4 | 5.0 | 6.5 | 9.8 | 17.7 | 29.2 |

| 7/16″ | 12 | 0.80 | 1.00 | 1.50 | 1.9 | 2.2 | 3.6 | 5.4 | 6.9 | 10.4 | 18.8 | 30.7 |

| 1/2″ | 13 | 0.80 | 1.10 | 1.50 | 2.0 | 2.4 | 3.9 | 5.8 | 7.4 | 11.1 | 19.8 | 32.2 |

| 9/16″ | 14 | 0.90 | 1.20 | 1.70 | 2.2 | 2.6 | 4.2 | 6.2 | 7.8 | 11.7 | 20.9 | 33.6 |

| 5/8″ | 16 | 1.00 | 1.30 | 1.80 | 2.3 | 2.8 | 4.5 | 6.6 | 8.3 | 12.4 | 21.9 | 35.1 |

| 3/4″ | 19 | 1.10 | 1.50 | 2.10 | 2.6 | 3.2 | 5.0 | 7.3 | 9.2 | 13.6 | 24.0 | 38.0 |

| 7/8″ | 22 | 1.30 | 1.70 | 2.30 | 2.9 | 3.5 | 5.6 | 8.1 | 10.1 | 14.9 | 26.1 | 41.0 |

| 1″ | 25 | 1.40 | 1.90 | 2.50 | 3.4 | 3.9 | 6.2 | 8.9 | 11.0 | 16.1 | 28.8 | 44.0 |

| 1-1/8″ | 29 | 1.50 | 2.00 | 2.80 | 3.8 | 4.3 | 6.7 | 9.6 | 11.9 | 17.4 | 30.2 | 47.0 |

| 1-1/4″ | 32 | 1.60 | 2.20 | 3.00 | 4.1 | 4.6 | 7.3 | 10.4 | 12.8 | 18.7 | 32.3 | 49.8 |

| 1-1/2″ | 38 | 1.80 | 2.50 | 3.50 | 4.7 | 5.3 | 8.3 | 11.9 | 14.7 | 21.2 | 36.5 | 55.8 |

| 1-3/4″ | 44 | 2.10 | 2.90 | 4.00 | 5.3 | 6.1 | 9.4 | 13.5 | 16.5 | 23.7 | 40.7 | 61.7 |

| 2″ | 51 | 2.40 | 3.00 | 4.50 | 6.0 | 6.8 | 10.6 | 15.0 | 18.3 | 26.2 | 44.8 | 67.6 |

| 2-1/4″ | 57 | 2.60 | 3.60 | 5.00 | 6.7 | 7.6 | 11.8 | 16.6 | 20.1 | 28.8 | 49.0 | 73.5 |

| 2-1/2″ | 64 | 2.80 | 3.90 | 5.50 | 7.3 | 8.3 | 12.9 | 18.1 | 22.0 | 31.3 | 53.2 | 79.5 |

| 2-3/4″ | 70 | 3.10 | 4.00 | 6.00 | 7.9 | 9.1 | 13.9 | 19.7 | 23.8 | 33.9 | 57.3 | 85.3 |

| 3″ | 76 | 3.40 | 4.70 | 6.50 | 8.6 | 9.8 | 15.0 | 21.2 | 25.6 | 36.4 | 61.5 | 91.3 |