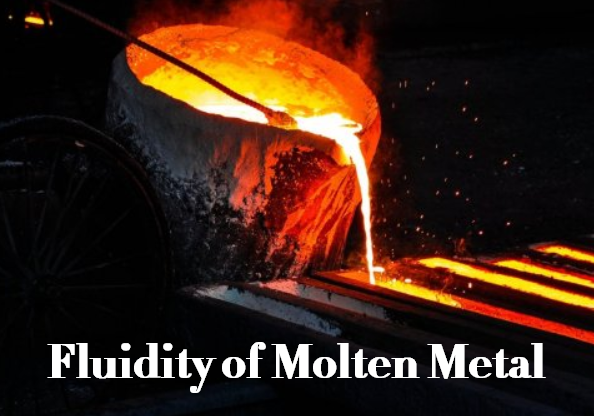

What is Fluidity of Molten Metal - Factors Affecting Molten Metal Fluidity

To obtain a perfect casting part, every parameter should be selected or determined carefully. Fluidity is an important measure in the die casting process, it has an impact on the quality of the final die castings. Now, to understand the fluidity, we’ll introduce what is fluidity of molten metal and focus on the factors affecting molten metal fluidity, so as to learn about how to increase the metal fluidity.

What is Fluidity of Molten Metal - How to Define the Metal Fluidity

The molten metal flow characteristics are often described by the term fluidity. There is a variety of methods to define the metal fluidity in casting.

The fluidity of molten metal can be defined as a measure of the capability of a metal to flow into and fill the mold before freezing. Fluidity is the inverse of viscosity, when viscosity increases, the fluidity decreases. Fluidity may be defined as an empirical measure of the distance a liquid metal can flow in a specific channel before being stopped by solidification. Physicists define fluidity as the reciprocal of the coefficient of its viscosity. Metallurgists define fluidity as the ability of liquid metal or alloy to flow freely, and thus to feed a mold cavity and produce the desired contour before freezing occurs. Fluidity refers to the ability of the liquid alloy to fill the mold. The fluidity can determine whether the alloy can produce more complex castings. Among the types of aluminum alloy, the fluidity of eutectic alloy is better.

Factors Affecting Molten Metal Fluidity - How to Increase Fluidity During Casting?

Fluidity is mainly affected by chemical composition, pouring temperature, and mold. Materials with good fluidity are easy to fill the mold cavity, so as to obtain castings with complete shape, accurate size, and clear outline. The fluidity of metal can be measured by the length of a helix. The longer the spiral line obtained under the same casting conditions, the better the fluidity of the liquid metal. The type and chemical composition of the alloy and the pouring process conditions are two main factors affecting the molten metal fluidity.

1. Types and chemical composition of alloys

Different kinds of alloys have different fluidities. According to the helix length measured by the fluidity test, the fluidity of gray cast iron is better, followed by silicon brass and aluminum-silicon alloy, while the fluidity of cast steel is poor.

In the same kind of alloy, the chemical composition is different, the crystallization characteristics of the alloy are different, and its fluidity is also different. Generally, the crystallization of alloys is completed in a temperature range. The primary crystal formed first during crystallization will hinder the flow of liquid metal; The eutectic alloy crystallizes at a constant temperature, has no initial product formation, and has little resistance to liquid metal. In addition, the melting point of the eutectic alloy is low. At the same pouring temperature, the eutectic alloy has enough time to fill the mold cavity before crystallization, so the casting performance of the eutectic alloy is excellent. The farther the composition of the alloy is from the eutectic point, the wider the crystallization temperature range and the worse its fluidity. Therefore, on the premise of meeting the service performance, eutectic alloy or alloy close to the common product composition should be selected as far as possible.

2. Pouring process conditions

Increasing the pouring temperature can improve the fluidity of metal. The higher the pouring temperature, the longer the metal remains liquid and the smaller its viscosity, so the better its fluidity. Therefore, properly increasing the pouring temperature is one of the process measures to improve the fluidity.

3. Other factors affecting the casting fluidity

In addition, the thermal conductivity of mold material, the shape and size of the mold cavity, and other factors also affect the fluidity. The internal factors are the composition, temperature, or the solid particles in the metal oxides, metal compounds, or other pollutants in the alloy liquid, while the external factors are caused by the pouring temperature or pouring pressure.

– Freezing range of alloy: fluidity is inversely proportional to the freezing temperature range.

– Latent heat of fusion of alloy: higher latent heat increases fluidity.

– Inclusions: insoluble particles can increase viscosity, while reducing fluidity.

– Surface tension: decreases fluidity, often caused by an oxide film.