The energy-saving requirements make the selection of product materials become more important, ductile iron is an increasingly considered material in the metal casting industry due to its great strength-to-weight ratio characteristics and relatively low cost. What is nodular cast iron? Why and when to use it? Take a look at the overview of ductile iron.

What is Ductile Iron – Nodular Cast Iron Definition

Ductile iron, also known as nodular cast iron, ductile cast iron, spheroidal graphite iron, and spheroidal graphite cast iron, is graphite-rich cast iron. Before pouring molten iron, add a small amount of spheroidizing agents, such as magnesium, calcium, and rare earth elements, and graphite agents, such as ferrosilicon and calcium silicon alloy to the molten iron to promote the existence of carbon in spherical graphite. This kind of cast iron is called nodular cast iron.

What advantages does ductile iron have?

Nodular cast iron is a high-strength cast iron material developed in the 1950s. Its comprehensive properties are close to steel. Based on its excellent properties, it has been successfully used to cast some parts with complex stress and high requirements for strength, toughness, and wear resistance. Nodular cast iron has rapidly developed into a widely used cast iron material second only to gray cast iron.

Because carbon (graphite) exists in the matrix of cast iron in a spherical shape, its splitting effect on the matrix is improved, and the tensile strength, yield strength, plasticity, and impact toughness of nodular cast iron are greatly improved. Nodular cast iron is much better than gray cast iron in strength, plasticity, toughness, and even close to steel; It has the advantages of wear resistance, shock absorption, good process performance, and low cost. It has widely replaced malleable cast iron and some cast steel and forged steel parts.

Ductile Iron Microstructure – What is the Microstructure of Nodular Cast Iron?

Ductile iron, a widely used material in the industrial field, has a unique microstructure. Simply put, the microstructure of ductile iron is mainly composed of spherical graphite, matrix structure, and their interrelationships.

Spherical graphite is a prominent feature of the microstructure of ductile iron. Compared to flake graphite in ordinary cast iron, spherical graphite greatly improves the performance of cast iron. Under a microscope, spherical graphite appears as round balls scattered throughout the matrix tissue. This spherical shape reduces the cutting effect of graphite on the matrix, making ductile iron have better mechanical properties, such as higher strength and toughness.

The matrix structure includes ferrite, pearlite, and their mixed structures. Ductile iron with ferrite matrix has good plasticity and toughness, while ductile iron with pearlite matrix has relatively high strength. Different proportions of matrix structure can lead to different comprehensive properties of ductile iron, meeting the needs of various engineering applications.

Ductile Iron Composition – What is Ductile Cast Iron Made of?

The typical composition range of ductile iron is as follows (by mass percentage):

- Carbon (C): 3.08%–3.9%, a core element for graphite spheroidization.

- Silicon (Si): 2.0%–4.5%, promotes graphitization and regulates the matrix structure.

- Manganese (Mn): 0.55%–7.0%, with higher levels in medium-manganese ductile iron to enhance wear resistance.

- Phosphorus (P) and Sulfur (S): Typically limited to low levels (P ≤ 0.15%, S ≤ 0.03%) to avoid brittleness.

Spheroidizing Agents and Alloying Elements

- Magnesium (Mg): It is the main component of spheroidizing agents, with a content generally ranging from 0.03% to 0.08%. Magnesium can spheroidize graphite in cast iron and improve its mechanical properties.

- Rare earth (RE): The content is usually between 0.02% and 0.05%. Rare earth elements can purify molten iron and improve the toughness and wear resistance of cast iron.

- Copper (Cu) and Molybdenum (Mo): Added in trace amounts to improve strength or heat resistance, such as in QT700-2.

Compositional Differences Between Different Types of Ductile Iron

- Ferritic Ductile Iron: High silicon content (2.4%-2.8%), carbon equivalent 4.4%-4.9%.

- Pearlitic Ductile Iron: Contains alloying elements such as molybdenum and copper to strengthen the matrix.

- Martensitic Ductile Iron: Strictly controlled sulfur and phosphorus content, with additions of magnesium and rare earth elements.

Ductile Iron Properties – What are the Advantages of Nodular Cast Iron?

Mechanical Properties

Tensile strength: 400-1400 MPa, which is the maximum tensile force a material can withstand before breaking. For example, the “400” in the common ductile iron QT400-18 indicates a tensile strength of at least 400 MPa, meaning it can withstand a tensile force of 400 Newtons per square millimeter without breaking. This varies significantly between grades (e.g., QT400-17 is 400 MPa, while QT900-2 reaches 900 MPa).

Yield strength: 50-800 MPa (e.g., QT450-10 has a yield strength of ≥250 MPa). This is the stress at which a material begins to undergo significant plastic deformation. For example, the yield strength of QT400-18 is generally around 250 MPa, meaning that when the external force reaches this level, the material begins to undergo irreversible deformation.

Elongation: 2%-24%, reflecting the material’s ductility (QT400-17 reaches 17%, while QT700-2 only has ≥2%). This refers to the ratio of the material’s elongated length after breaking under tension to its original length, expressed as a percentage. The “18” in QT400-18 indicates an elongation of at least 18%, indicating that this ductile iron can deform significantly before breaking, making it relatively “soft” and possessing a certain degree of toughness.

Hardness: 160-305 HB, measuring the material’s ability to resist the impact of hard objects. Pearlite (e.g., QT700-2. with a hardness of 225-305 HB) is higher than ferrite (QT450-10. with a hardness of 160-210 HB). Ductile iron with higher hardness is more wear-resistant, but may also have lower toughness. Impact toughness: 6-18 J/cm² at room temperature, remaining stable at low temperatures (e.g., QT450-10 low-temperature impact value ≥18 J/cm²).

Physical Properties

Density: 7.1-7.3 g/cm³, which is the mass per unit volume. Ductile iron has a density similar to that of iron, making it heavier than some aluminum alloys but lighter than heavy metals like lead.

Coefficient of Thermal Expansion: 12-13 × 10⁻⁶/°C, indicating the degree to which a material expands or contracts with temperature changes. This means that for every 1°C increase or decrease in temperature, a unit length of ductile iron will expand or contract by 12-13 × 10⁻⁶ times.

Thermal Conductivity: Between 30-40 W/(m·K), a measure of a material’s ability to conduct heat. Ductile iron has reasonable thermal conductivity. It’s not a poor conductor of heat like plastics, but it also doesn’t conduct heat as quickly as metals like copper and aluminum.

Advantages:

High Strength – Ductile cast iron’s strength is over 50% higher than that of ordinary gray cast iron, reaching the strength level of typical cast steel. This is due to the ductile iron’s spheroidal graphite, which significantly enhances the material’s strength and toughness.

High Toughness – Ductile cast iron’s toughness is over twice that of ordinary gray cast iron, offering excellent tensile strength and impact toughness. Its toughness is particularly pronounced under high-strength conditions.

High Wear Resistance – Ductile cast iron’s wear resistance is over three times higher than that of ordinary gray cast iron, making it an ideal wear-resistant material. The ductile iron in ductile cast iron offers high wear resistance, effectively resisting abrasion and impact.

Excellent Corrosion Resistance – Ductile cast iron exhibits superior corrosion resistance compared to ordinary gray cast iron, offering excellent resistance to corrosion from oxidizing agents, acids, alkalis, and other chemicals. This is due to the presence of alloying elements such as chromium and nickel in ductile iron.

Easy Machinability – Ductile cast iron has excellent machinability and can be easily formed into a variety of shapes. Ductile iron has a moderate hardness, is not susceptible to tool damage, and is relatively easy to machine.

Excellent Fatigue Resistance – Ductile iron has excellent fatigue resistance and can withstand repeated cyclic loading. This is because the ductile iron’s spheroidal graphite effectively absorbs and distributes loads, thereby extending the material’s fatigue life.

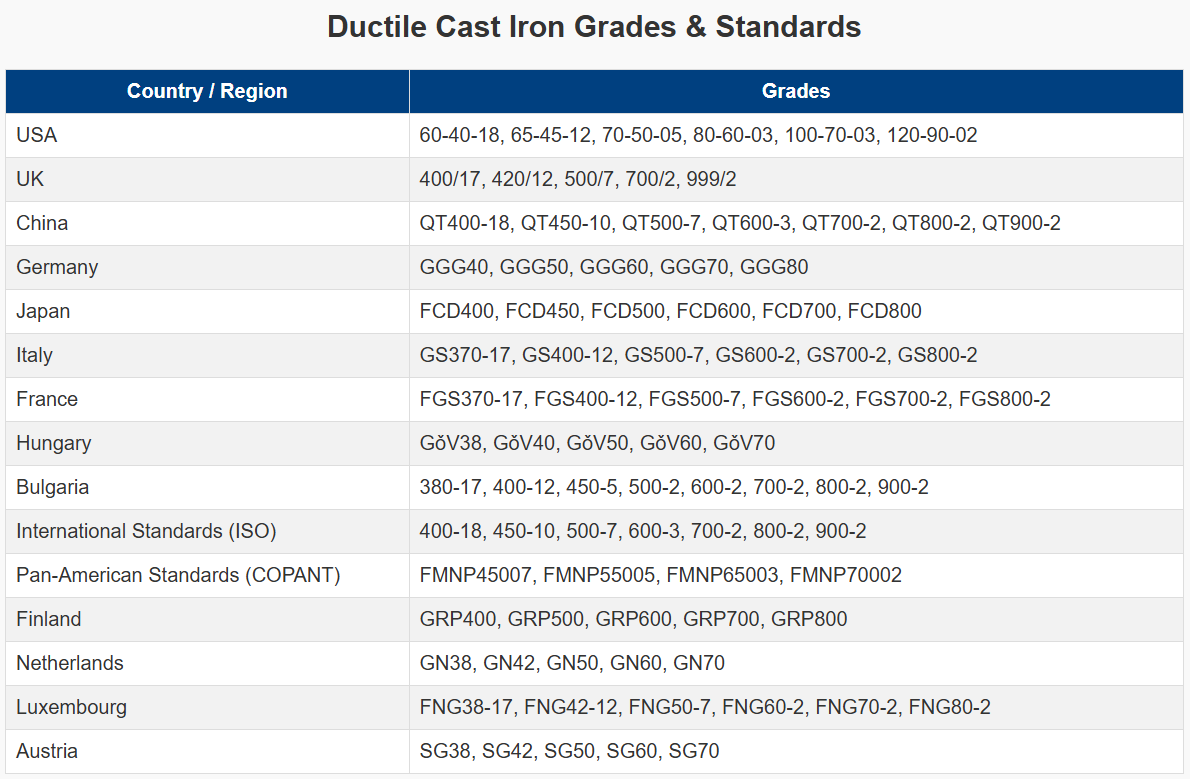

Ductile Cast Iron Grades & Standards

The following is a list of ductile iron grades from some countries and regions:

Ductile Iron Applications – What is Ductile Iron Used for

What are ductile iron and ductile iron castings used for?

1. Piping and fittings

Ductile iron pipes are better than gray iron pipes in transporting water and other liquids. The main reason for this transformation lies in the combination of strength and toughness of ferritic nodular cast iron so that the pipeline made of this material can withstand high operating pressure and can be loaded and unloaded carelessly during laying. The mat gas transmission pipeline must be able to withstand the requirements of multiple-use conditions, i.e. excavation near the pipeline, municipal engineering construction, transportation, etc

2. Automotive industry

The automotive industry is the second user of ductile iron castings. Ductile iron is used in three main places in automobiles: the first is engine parts, the second is gears and shaft sleeves, and the third is vehicle suspension, brake, and steering device. Most gasoline engines in the world are equipped with nodular iron crankshafts instead of forged steel crankshafts. Ductile iron with excellent properties is replacing gray cast iron in the exhaust pipe. With the increase of temperature, silicon aluminum alloy ductile iron will be further used. Malleable cast iron parts for automobile power transmission are sometimes used as transmission parts of automobiles. There is a strong trend to apply ductile iron to disc clutch, speed divider box, rear axle, and wheel housing. Ductile iron is often used as suspension components, such as spring hooks, as well as the main safety components of braking systems and steering joints.

3. Agricultural, road, and construction applications

Ductile iron castings widely used in the whole agricultural industry include various tractor accessories, brackets, clamps, and pulleys. The typical component is the two rear axle shells of agricultural vehicles, which originally used steel castings. Road laying and construction industries need a considerable number of various types of equipment, including bulldozers, percussion machines, cranes, and compressors. Ductile iron castings are used in these aspects.

4. Valve manufacturing

Valve manufacturers are the main users of ductile iron (including austenitic ductile iron). Their applications include the successful transportation of various acids, salts, and alkaline liquids.

5. General purposes

The machine tool industry utilizes the engineering properties of ductile iron, which allows the design of complex machine tool parts and castings Ductile iron has high tensile strength and yield strength, and good machinability. It allows the production of lighter castings to keep them rigid. Similarly, the strength and toughness of ductile iron make it an ideal material for various hand tools, such as wrenches, clamps, and measuring tools. Similarly, ductile iron rolls are used in steel mills, which have higher properties than steel and chilled cast iron.

Ductile Iron (Nodular Cast Iron) FAQs

What is Ductile Iron Pipe?

Ductile iron pipes are commonly used for connecting medium- and small-diameter water supply lines. The main connection methods are socket joints or flange joints. This type of pipe material has excellent seismic resistance and sealing performance, ensuring stability and durability in various environments.

The primary components of ductile iron pipe include carbon, silicon, manganese, sulfur, phosphorus, and magnesium, and its production complies with the ISO 2531/2003 standard. It is manufactured by adding a spheroidizing agent to molten iron (with a grade of No. 18 or higher), followed by high-speed centrifugal casting using a centrifugal ductile iron machine. Hence, it is called ductile iron pipe.

When was Ductile Iron Pipe First Used?

The earliest use of ductile iron pipes can be traced back to the 1668 water pipeline from the Seine River to Versailles in the suburbs of Paris, which is still in use today (except for some repairs and replacements).

In 1947. British scientist H. Morrogh discovered that adding cerium could make graphite spherical, but it was not widely promoted due to the high price of cerium. In 1948. American scientists A.P. Ganganebin and others improved the process by replacing cerium with magnesium, enabling large-scale industrial production of ductile cast iron pipes.

In the 1950s, European and American cities began using it to replace traditional gray cast iron pipes for water supply systems. In the 1960s and 1970s, it expanded to the industrial sector (such as mine drainage and chemical transportation). After the 1980s, centrifugal casting technology and anti-corrosion technology matured, further expanding their application scope.

Is Ductile Iron the Same as Cast Iron?

Cast iron and ductile iron (nodular cast iron) are not the same material. Cast iron mainly includes gray cast iron, white cast iron, etc., while ductile iron uses special processes to distribute graphite in a spherical shape, improving the strength and toughness of the material. The two differ in composition, properties, and applications.

What s the Difference Between Ductile Iron and Cast Iron?

1. Strength and toughness: Ductile iron has higher tensile strength and yield strength than ordinary cast iron, and its toughness is significantly improved, allowing it to withstand greater impact loads.

2. Weldability and Machinability: Although cast iron has relatively poor weldability and machinability, ductile iron can achieve better welding and processing effects by optimizing heat treatment processes and selecting suitable welding materials.

3. Corrosion resistance: There is no essential difference between the two in terms of corrosion resistance, which depends on the specific alloy composition and usage environment.

4. Cost: Due to the relatively complex production process of ductile iron and the need to add additional spheroidizing agents and inoculants, its cost is usually higher than that of ordinary cast iron.

Can You Weld Ductile Iron?

Yes, ductile iron (nodular cast iron) can be welded! However, due to its special material and welding requirements, special welding processes and methods are needed to ensure the quality and reliability of welding.

Is Ductile Iron Magnetic?

Ductile iron (Nodular Cast Iron) has a certain degree of magnetism, which is determined by the microstructure and chemical composition of the cast iron. Ductile iron contains ferrite and residual austenite phases, which have irregular shapes and are therefore affected in the direction of the magnetic field, exhibiting a certain degree of magnetism.