There are several methods for custom clothing printing, but the two most popular ones are DTG (Direct-to-Garment) printing and silk screen printing. Choosing the right business model for your online e-commerce venture is the first essential step to satisfy customers, save costs, and allow for scalability as your business grows. In this article, we’ll explore the differences between DTG and screen printing, their suitable designs, and the sustainability of each technique. It’s crucial to research your choice by asking questions about the two printing methods, such as:

-Is it suitable for my products?

-What’s the cost-effectiveness?

-Is it environmentally friendly?

What is Screen Printing?

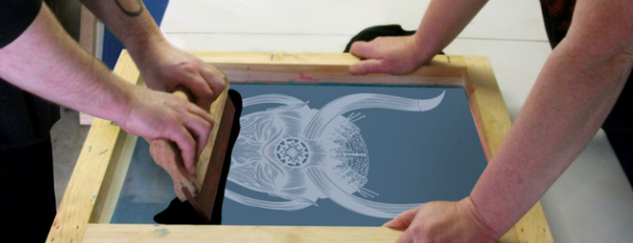

Screen printing is a printing method where ink is pushed onto fabric through a woven mesh (also known as a screen template). The ink doesn’t soak into the fabric but sits on top of the product.

How does Screen Printing Work?

With screen printing, special screens need to be made for each element of the design. Once done, colors and elements of the design are applied layer by layer onto the garment. The more layers your design has, the longer the printing process and the thicker the design on the product. The lengthy setup time is why screen printing is primarily used for bulk printing projects. If creating templates for your design takes hours, printing just a few t-shirts isn’t cost-effective.

Because each color is applied separately, screen printing is also primarily used for designs with fewer colors. Print providers often limit the number of colors that can be included in a design, usually not allowing more than nine.

Is Screen Printing Environmentally Friendly? Is It Expensive?

As a business, it’s important to understand how your operations impact the environment. Sellers using screen printing typically place bulk orders and send out products as orders come in. This is why there’s a possibility of overproduction, a key issue being tackled by the sustainable fashion movement.

If your screen-printed products don’t sell, they might end up in landfills or incineration, leading to pollution. More significantly, screen printing uses a lot of water and often employs non-biodegradable plastic-based ink and solvent for the screens, which are not eco-friendly.

The cost of screen printing depends on the quantity of items you order. For instance, if you’re ordering in bulk, screen printing is usually the most cost-effective choice. This is because screen printing templates are manually created and take time to prepare.

Is Screen Printing of Good Quality? Is It Durable?

Screen printing technology is known for its quality. The colors are vibrant, and the prints are highly durable. For optimal results, it’s advised to use simple designs with fewer details or colors for screen printing.

Screen-printed shirts last if cared for properly. To avoid ink cracking, peeling, and fading, avoid washing screen-printed garments in hot water, steer clear of bleach, and always turn them inside out before washing.

Is Screen Printing the Right Choice for Your Business?

The final cost of bulk orders for screen printing depends on the number of colors in your design and the screens needed for printing. Therefore, if you’re just starting out or want to experiment with designs, it can be financially challenging.

Bulk ordering also means storing printed garments. This limits the number of designs you can offer in your store as each design needs to be printed in bulk. Also, consider if you can sell all the printed items so you don’t create textile waste. This can be tricky to predict for entrepreneurs who haven’t established a customer base yet.

Some print services might require you to submit print files divided into color layers. They might ask for color codes for inks to be used in printing your design. So, if you’re looking for an “upload your design and forget the rest” type of experience, screen printing might not be the right choice for you.

DTG Printing: Suitable for 100% Cotton, but cotton blends work as well. The primary advantage is that printing one-offs is easy, as there’s almost no setup time.

In addition, you can use intricate designs and color patterns as needed. For optimal results, create graphics in color profiles that match the possibilities of DTG printer colors.

Is DTG Printing Environmentally Friendly?

DTG is a more sustainable fashion business model compared to screen printing. This is mainly because on-demand printing allows businesses to avoid overproduction and textile waste. The fashion industry wastes around 92 million tons of textiles each year, a problem that models like this aim to change.

How Long Does DTG Printing Last?

DTG prints can last a long time with proper care. Follow care instructions to prevent fading or cracking, gently machine wash garments, avoid bleach and fabric softeners, and don’t iron directly on the print.

Is DTG Printing the Right Choice for Your Business?

Most third-party printers don’t have minimum order quantities for DTG products, so you don’t need to worry about inventory. This method also allows businesses to use print-on-demand services.

With DTG, the entire design can be printed in one go. Since DTG doesn’t have color counts, there’s no extra setup time required to start printing, so once the print file is through, your order gets fulfilled. This printing model allows you to introduce new designs or enter new markets freely without losing any funds. If products don’t sell, you can pause production or switch designs.

Screen Printing vs. DTG: Which One Is Right for You?

Both DTG and screen printing yield high-quality prints, but they differ in method and cost.

DTG and screen printing are both effective methods, but they cater to different needs and business situations. Here’s a summarized comparison to help you decide which method might be more suitable for your online e-commerce business:

Screen Printing:

- Ideal for bulk orders due to setup time and manual template creation.

- Best suited for designs with a limited number of colors (usually up to nine).

- Requires careful consideration of environmental impact due to water usage and non-biodegradable inks.

- Offers high-quality, vibrant prints that are durable.

- Considerable initial investment and storage required for bulk orders.

- Suitable for businesses with an established customer base and predictable demand.

DTG Printing:

- Can cater to one-off or low-quantity orders as there’s minimal setup time.

- Suitable for detailed designs and multi-color prints.

- Generally considered more environmentally friendly due to on-demand production and reduced waste.

- Offers high-quality prints that can last a long time with proper care.

- No minimum order requirements, making it flexible for small businesses and experimentation.

- Allows for the introduction of new designs without the risk of unsold inventory.

- Well-suited for businesses without a well-established customer base.

The choice between screen printing and DTG depends on your specific business model, budget, the complexity of your designs, and your commitment to sustainability. It’s advisable to thoroughly evaluate your business needs and the implications of each method on your operations, costs, and environmental impact before making a decision.