When it comes to die casting simulation technology, we should have a deep feeling. In recent years, with the popularization of computer technology in the engineering field and the gradual improvement of computer performance, more and more die-casting parts will be simulated and calculated by engineers before actual die-casting production. The purpose is to avoid the waste of time and material costs caused by design errors to the maximum through virtual simulation calculation.

Thanks to the application of high-performance die-casting machines, a large number of process curves formed in the production process of die-casting parts have been collected, which truly reflect the change laws of various parameters in the production process of die-casting. By analyzing and interpreting the information, it is helpful to help die-casting practitioners to carry out die-casting parts development, die-casting mold design and die-casting process design. Next, we will interpret the die casting simulation report in detail through a case. This report is generated based on the die casting simulation software, and the corresponding actual process curve is automatically mapped by the Buhler die casting machine.

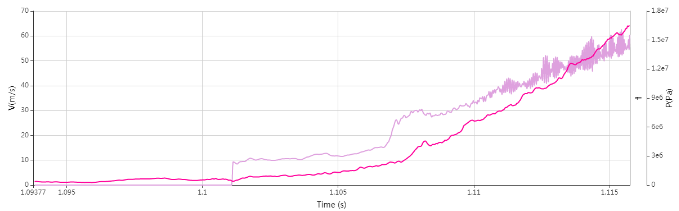

First, let’s understand the above two curves as a whole:

VL “line is the punch speed curve set by the die casting machine; In the actual injection process, the movement speed of the punch always follows the law of this curve, and the actual speed curve of the punch is “VL a”. It can be seen that the VL a line always fits the VL line, which is ensured by the closed-loop servo control system of the high-performance die casting machine.

In the monitoring curve of the sensor, it can be found that the pressure of molten metal and the filling speed also gradually increase with the passage of time. The pressure and speed changes in the curve also follow the speed curve set by the simulation software

Then, we will study the injection curve by sections:

The first stage: that is, the punch moves slowly. As soon as the injection button of the die-casting machine is started, the punch moves to the parting surface at a low speed, slowly pushing the metal liquid level in the pressure chamber to a high level. This process should ensure that the metal liquid will not turn over and form a roll in the pressure chamber

The second stage: metal high-speed filling stage, the metal breaks through the resistance at the ingate and fills the mold cavity at high speed until the cavity is filled

The third stage: at the end of the injection stroke, the end face of the punch is suddenly braked, and the injection pressure suddenly increases. After the metal liquid fills the mold cavity, it solidifies under the high pressurization pressure to form a casting.

Tips: the low-speed stage includes the time when the punch starts to move until the molten metal flows to the vicinity of the ingate. The resistance of the punch is small, generally below 50bar. If the monitoring curve shows that it is much greater than 50bar, attention should be paid to the matching gap between the surface of the pressure chamber and the punch. It may be that the gap is too large, and the sheet metal formed by the condensation of the alloy liquid fills the gap, resulting in increased resistance; It is also possible that the cooling water channel of the punch is blocked, the punch heats too fast, and the thermal expansion causes the punch to be stuck with the surface of the pressure chamber.

It can also be seen from the monitoring curve generated by the simulation software that when the molten metal flows through the ingate, the resistance value of the sensor set on the end face of the punch also begins to increase. The simulation calculation shows that when the molten metal reaches the ingate, the pressure value of the punch end face is close to 10MPa, while the pressure value of the punch end face actually displayed by the die casting machine is about 12.3mpa. The simulation calculation result basically conforms to the measured value.

By comparing the change laws of the sensor monitoring curve of the simulation software and the process monitoring curve of the die casting machine, it can be found that there are laws in the process of filling the mold cavity with molten metal:

1) As the molten metal flows to the mold cavity at a high speed, the pressure value at the end face of the punch reflected on the injection curve will rise synchronously and slowly until the cavity is full, and the peak value will be reached when the pressurization is started;

2) If there is a pressure surge during the filling stage, check the fit between the punch and the surface of the pressure chamber. It is possible that the poor lubrication between the surface of the pressure chamber and the punch may increase the punch resistance;

3) If the pressure drops sharply after the pressurization is started, the setting of the injection process curve should be checked. It may be that the conversion conditions are not set properly. For example, if the conversion is advanced, the pressurization is started before the molten metal has filled the cavity, which usually causes the pressure to drop sharply and leads to ineffective pressurization.

Familiar with the laws of these changes, you can easily face the design of the pouring system of the die-casting die and the development of the die-casting process.