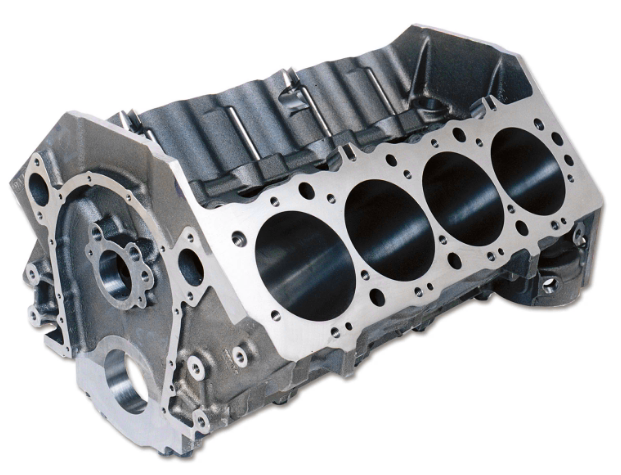

Engine blocks are one of the types of automotive casting parts, how do they cast and what materials and processes are involved?

How Are Engine Blocks Cast?

Engine blocks are typically produced using sand-casting or die-casting processes. Here is an overview of how engine blocks are cast using sand casting:

– Pattern Making: The first step in the sand casting an engine block is to create a pattern of the desired shape and size. The pattern is usually made from wood, metal, or plastic and represents the final shape of the engine block.

– Mold Making: Once the pattern is made, a mold is created by packing sand around the pattern. The sand is mixed with a bonding agent and compacted to form the mold cavity.

– Core Making: Cores are typically used to create the internal cavities of the engine block such as the cylinder bores and water jackets. The cores are made from sand and binder material and are placed inside the mold cavity before the molten metal is poured.

– Pouring: Molten metal is poured into the mold cavity through a sprue and runner system. The metal fills the mold cavity and solidifies around the cores and pattern.

– Cooling and Shakeout: Once the metal has solidified, the mold is cooled and then shaken or vibrated to break it apart and remove the casting.

– Finishing: The casting is then cleaned up and machined to remove any excess material and to create the final shape and size of the engine block.

Casting is a popular method for producing engine blocks due to its ability to create large, complex shapes and its relatively low cost compared to other casting methods.

Are Engine Blocks Made of Cast Iron or Cast Steel?

Engine blocks can be made from various materials such as cast iron, aluminum, or steel depending on the specific application and requirements of the engine. However, traditionally, engine blocks were primarily made from cast iron due to their high strength, wear resistance, and thermal conductivity.

Cast iron engine blocks are produced using either the sand casting or the lost foam casting process. In the sand casting process, a pattern of the engine block is created from wood, metal, or plastic, and sand is used to create the mold. Molten cast iron is then poured into the mold and allowed to solidify before the casting is removed from the mold and cleaned up. In the lost foam casting process, the pattern is made from expanded polystyrene foam, which is coated with refractory material and then buried in the sand. Molten cast iron is poured into the mold, which vaporizes the foam pattern and fills the void to create the casting.

On the other hand, steel engine blocks are less common than cast iron or aluminum engine blocks, but they do exist. Steel engine blocks are typically produced using the sand casting or investment casting process, which involves creating a wax or foam pattern of the engine block and then coating it with a refractory material before pouring molten steel into the mold.

Can You Weld a Cast Engine Block?

Welding a cast iron engine block is possible, but it requires specialized skills, equipment, and techniques. Cast iron is a brittle material and is prone to cracking when exposed to heat, which makes welding challenging. To successfully weld a cast iron engine block, the following steps are typically followed:

– Preheat the Engine Block: The engine block is preheated to a specific temperature to help reduce thermal stress during welding.

– Choose the Right Welding Process: There are several welding processes that can be used for welding cast iron, including gas tungsten arc welding (GTAW), shielded metal arc welding (SMAW), and oxyacetylene welding (OAW).

– Use the Right Filler Material: A specialized filler material such as nickel-based or iron-based rods is typically used for welding cast iron.

– Control the Heat: The heat input must be carefully controlled during welding to prevent overheating, which can cause the cast iron to crack.

– Post-Weld Heat Treatment: After welding, the engine block is typically heat-treated to relieve stress and improve the strength of the weld.