A sprue refers to a large diameter channel through which the material enters the mold. What are the functions and types of sprues?

What are the Different Types of Sprues?

In sand casting, a sprue is a channel or passageway that allows molten metal to flow into the mold cavity. There are several types of sprues, each of which is used for a specific purpose:

– Single sprue: A single sprue is the simplest type of sprue, and involves pouring the molten metal into a single opening at the top of the mold.

– Multiple sprues: Multiple sprues are used for larger, more complex molds. They involve pouring the molten metal into several smaller sprue openings, which then feed into the main mold cavity.

– Top gating: In top gating, the sprue is located at the top of the mold, and the molten metal flows downward into the mold cavity.

– Bottom gating: In bottom gating, the sprue is located at the bottom of the mold, and the molten metal flows upward into the mold cavity.

– Diagonal gating: Diagonal gating involves angling the sprue at a diagonal angle, which helps to prevent turbulence and improve the flow of the molten metal.

– Side gating: Side gating involves positioning the sprue at the side of the mold, rather than at the top or bottom.

The choice of sprue type will depend on factors such as the shape and size of the part being cast, the desired surface finish, and the type of metal being used. A well-designed sprue system can help to ensure that the molten metal fills the mold cavity evenly and smoothly, producing high-quality casting.

What is the Function of Sprue in Casting?

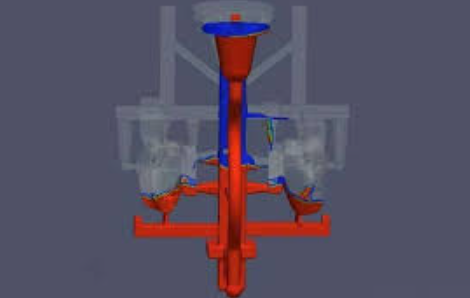

The sprue is a channel or passageway in sand casting that allows the molten metal to flow from the pouring basin into the mold cavity. The primary function of the sprue is to provide a controlled and consistent flow of molten metal into the mold cavity, ensuring that the entire cavity is filled before the metal solidifies. The sprue also serves several other functions in the casting process, including:

– Feeding system: The sprue is the main component of the feeding system, which also includes runners and gates. This system is responsible for directing the flow of molten metal into the mold cavity, and ensuring that it fills the entire cavity before solidifying.

– Venting: The sprue also serves as a venting system, allowing air to escape from the mold cavity as the metal fills it. This prevents the formation of air pockets or voids in the casting.

– Heat dissipation: The sprue helps to dissipate the heat generated by the molten metal as it enters the mold cavity. This helps to prevent the formation of hot spots or other defects in the casting.

– Removal: Once the casting has solidified, the sprue and any attached gates or runners can be removed from the casting. This process, known as risering, involves cutting or breaking off the sprue and any excess material, leaving only the finished casting.