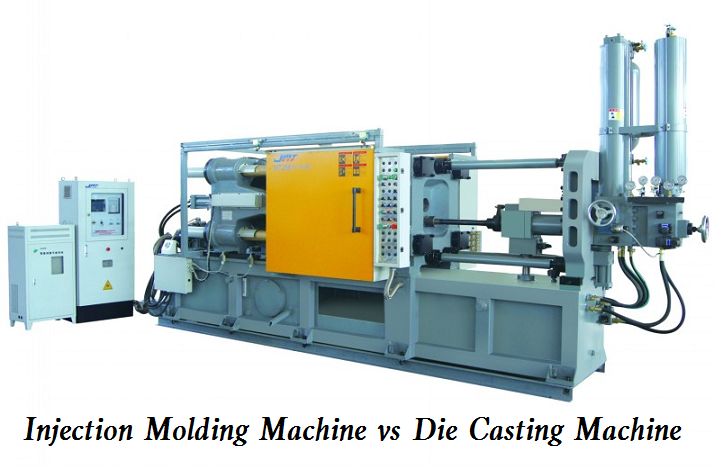

Injection molding and die casting are similar processes, when it comes to equipment, what are the differences between an injection molding machine and a die casting machine?

What is an Injection Molding Machine?

Injection molding machines are the primary molding equipment used to transform thermoplastic or thermosetting plastics into plastic items of varying shapes using vertical, horizontal, and all-electric molding molds. Plastic white metal goods with intricate shapes, precise dimensions, or dense textures find widespread application in the national defense, electromechanical, automotive, transportation, construction materials, and packaging industries, among others. With excellent production efficiency and simple automation, injection molding technology is suited to all types of plastic manufacture. Injection molding machinery plays an important role in the injection molding industry. The working principle of the injection molding machine is to inject molten plastic (i.e. viscous flow state) into the closed injection cavity under the push of the screw (or plunger) and then solidify it.

What is a Die Casting Machine?

A die casting machine is a machine used for die casting. It includes two types, the hot chamber, and cold chamber die casting machines. Later, they can be further divided into the straight type and the horizontal type. Under the action of pressure, the die-casting machine injects molten metal into the mold hydraulically for cooling and forming. After the mold is opened, solid metal castings can be obtained.

Differences Between Injection Molding Machine and Die Casting Machine

The injection molding machine is designed by imitating the die-casting machine because it is imitated. The clamping parts of the two are the same, with three differences

1. Mold clamping force

Compared with the injection molding machine, the injection speed of the die-casting machine is faster, the impact force is greater, and the kinetic energy is naturally greater. The speed of the injection molding machine to eject the piston is 0.2 meters, and the speed of the die-casting machine to eject the piston is several times higher than the injection molding machine, about 5-10 meters. It can be seen from the comparison of piston speed that the kinetic energy of the two is very different. For example, when driving against a wall and stepping on the clutch, the kinetic energy can only act on the wall. If you do not step on the clutch, the kinetic energy and engine thrust will be superimposed. At this time, the hydraulic pressure and kinetic energy will be superimposed in the mold cavity, and the kinetic energy is not large, because the injection speed is equivalent to the speed of people running. The key is to look at the buffer. The kinetic energy may be released in the cavity within one millisecond, this is not absolute. The kinetic energy may also be released in the cavity for more than ten milliseconds. The difference in instantaneous released power is very obvious.

2. Die-casting machine is a duplex pump

Compared with the double pump die-casting machine, the injection molding machine is a single pump. Because the injection form of the injection molding machine is high pressure and high speed (relative to the pump displacement is high speed), the injection molding machine can only use a single pump large motor. Compared with the injection molding machine that can only use a single pump and large motor, the pressure of the die-casting machine is driven by the accumulator. The charging time of the accumulator is very short, about 4 seconds, and the release time is very fast, about 2 seconds. The other cylinders of the machine do not have high pressure and high speed at the same time. Therefore, the die-casting machine uses two pumps, a small high-pressure pump to handle high pressure, and a large low-pressure pump to handle high speed. Theoretically, the motor power of the die-casting machine is less than that of the injection molding machine.

3. Output power

The die-casting machine is called press injection, and the injection molding machine is called injection. If the injection velocity is 30 times of the injection velocity, that is, the injection flow is 30 times of the injection flow, assuming the same injection pressure, that is, the injection power must be 30 times of the injection power. Therefore, to drive the injection, the motor must be increased by at least 30 times.mold clamping force