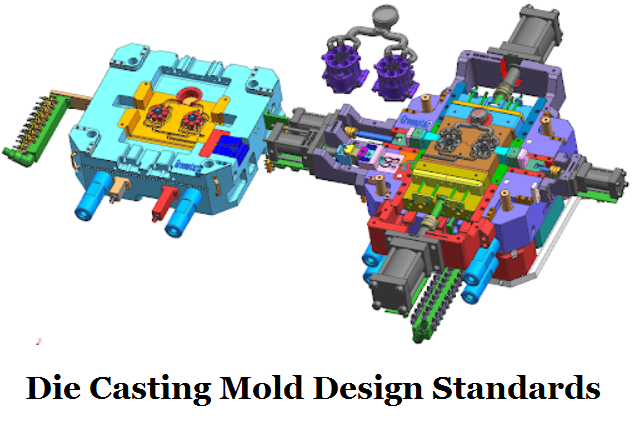

Die Casting Mold Design Standards & Tips - How to Design a Casting Mold | Diecasting-mould

Die casting mold requires high reliability and long service life. The combination of the casting mould, die casting machine, and die casting process is an effective casting production system. Optimizing the die casting mold (die) design and improving the casting process will ensure the reliability for the manufacturing of metal castings, this is also what Diecasting-mould.com always pursuing.

Die Casting Mold Design Requirements & Principle

The die in die casting has the same shape as the die casting parts to be produced, the design of mold will have an impact on the use of the mold, production cycle, cost, and more. Let’s take a look at the requirements, principles, and standards of the die casting die design.

1. The die casting mold should adapt to the requirements of casting production. The gating system and overflow system should be selected in accordance with the die casting process, especially the location of the inner gate, the speed of the inner gate, and the direction of the liquid flow. The liquid metal flow should be stable and smooth, and the gas in the mold cavity should be removed orderly, so as to achieve a good filling effect and avoid casting defects.

2. On the premise of ensuring the stable quality and safe production of die castings, the die casting die should have the following features:

(1) The structure is simple, advanced, and reasonable, the operation is accurate and reliable, and the operation procedure is reduced.

(2) It is easy to operate, safe and fast, easy to disassemble vulnerable parts, easy to maintain, and low manufacturing cost.

(3) It has high die casting efficiency, fast mold filling and opening, flexible and reliable demoulding mechanism, and a high degree of automation.

3. The die should meet the requirements of the mechanical processing and heat-treatment process. Select the right materials, for example, when the parts directly in contact with other molten metal, high-quality heat-resistant steel should be selected and hardened to make it have comprehensive mechanical properties such as thermal deformation resistance, fatigue strength, hardness, and corrosion resistance.

4. The mold design should fit the economy and feasibility.

(1) The overall structure of the mould is simple and practical, and the comprehensive cost is low.

(2) Economical and practical dimension matching accuracy should be selected.

(3) Reduce the consumption of surplus materials in the pouring system.

5. The die casting die should be rigid enough to not deform under the clamping force of the die casting machine.

6. The mold should not be too heavy, which is convenient for loading and unloading, repair and transportation, and reduce the load of the die casting machine.

7. The pressure center of the die cavity should be close to the center of the clamping force of die casting machine as far as possible, so as to prevent uneven stress of die casting machine, resulting in loose mold locking and rough edge of casting.

8. The shape of the die should be matched with the specifications of the die casting machine:

(1) The length and width of the mold should not interfere with the ejector;

(2) The total thickness of the mold should not be too thick or too thin, which is beyond the clamping range of the die casting machine;

(3) Pay attention to the matching with the material pipe or nozzle;

(4) When using the pull rod to pull back the ejection mechanism, pay attention to the matching of the size and position of the pull rod.

9. In order to facilitate the handling and assembly of the mold, screw holes should be drilled above and on both sides of the fixed die and moving die, so as to screw in the lifting ring screw.

Die Casting Mold Design Standards

The design of the die cavity and core:

1. The thickness of the lowest surface of the mold core is not less than 35mm, and the distance between the product edge and the mold edge is not less than 45mm. If the product is large, it should be increased accordingly.

2. If there are high ribs or grooves on the mold core, for the convenience of manufacturing and maintenance, the mold core should be inlaid as far as possible

3. In order to ensure the smooth demoulding, the inner surface of the product should be placed in the moving mold as far as possible. If there is no obvious inner surface, most of the surface of the product should be placed in the moving mold

4. The hardness of the die core is specified as follows: HRC:48 ±1°

The die of the mold frame:

1. In order to prevent the pit on the roof caused by repeated ejection, the hardness of the roof should be kept at about HRC48.

2. In order to prevent the deformation of the roof and the strength of the formwork, it is required to add a bottom plate and supporting column (EGP), needle plate guide column (EGP), and limit column (STB) at the bottom of each set of formwork.

3. The upper limit block should be added to protect the ejector pin. The four corners of the movable mold should be provided with a prying groove (the depth of the prying groove is 8mm), and four prying holes (∮ 20-30mm through-hole) should be made on the movable and fixed mold frame to facilitate the removal of the mold.

4. The position of the guide pillar hole should be the same, and the other one should be 1 ~ 2mm inward to prevent the reverse direction of the moving and fixing die during the die assembly.

5. In order to facilitate the installation, the four sides of the mold should be provided with lifting ring threaded holes, and the balance problem should be considered. The threaded holes should be M20, M24, M30, M36, and other specifications (the total weight of the mold should be considered).

6. The size of the clamping groove below 150 tons (including 150) is 25 * 25, and that of over 150 tons is 30 * 30.

The design of the slide:

1. The material of the slide shall ensure a certain strength and hardness, and the bottom of the sliding block shall be added with a wear-resistant plate, pressing strip, and back wear-resistant block.

2. In order to prevent deformation caused by pressure, the locking block of the slide shall ensure sufficient strength.

3. The slider and core pulling need to be fully positioned in the direction of mold opening.

4. The spring and inclined guide pillar shall have a certain strength, and the diameter of the inclined guide pillar shall be more than ¢ 20.

5. Screw and positioning pin shall be used to fix the slider and slide body.

6. The slide body extends into the mold core (F = 15-20 mm).

7. The slide insert should be a straight body and made of the hanging platform, and the inclination can not be made (the angle can be made at the place where the fixed die is inserted).

The design of sprue bush and sprue spreader:

1. Select SKD61 or DAC as the material of sprue bush and sprue spreader, and the hardness is about HRC48.

2. The gradient between sprue bush and sprue spreader shall not be less than 5.5 degrees.

3. The thimble hole on zinc alloy sprue spreader shall not be less than 5mm, and that of aluminum-magnesium alloy shall not be less than 8mm.

4. The material thickness at the zinc alloy sprue bush shall not be less than 5 mm, and the material thickness at the thinnest part at the back end of the magnesium alloy gate shall not be less than 10 mm.

Die Casting Mold Design Tips

1. Understand the structure, application of die casting mold

Fully understand the use of die casting mold and how the mold assembly with other structural parts, and considering the structural characteristics and performance of the casting die, distinguish the primary and secondary in mold design, highlight the focus of die structure and combine with the processing technology of die. Reasonably select parting surface, the quantity, and layout of cavity, ejection, and side demoulding form of die casting parts.

2. Understand the processing capability of mold

Understand the actual processing capacity of the mold, such as the existing equipment and the equipment of the cooperation unit, as well as the technical level of the operators, combined with the actual design of mold structure in line with the field processing capacity.

3. Consider temperature effects

The influence of die temperature change on the fitting accuracy of relative sliding parts should be fully considered.