Die Casting Guide - Advantages, Disadvantages, And How To Prevent Common Defects Of Die Casting

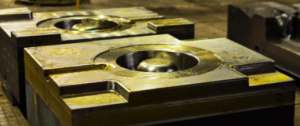

Die casting processes are used to make a wide range of products, from cylinder heads and engine blocks to furniture and bicycle frames. Die casting is a general casting process, which has both advantages and disadvantages for manufacturers. Many different metals and alloys are suitable for die casting. Zinc is a common choice for this casting process because of its high ductility and high strength, and it is relatively cheap, so it is very suitable for large-scale manufacturing applications. Other metals that can be used for die casting are aluminum, magnesium, copper, lead, tin and their corresponding alloys. On this die casting guide, we will go over the advantages and disvantages of die casting, as well as how to prevent defects.

Advantages Of Die Casting

Because die casting is a pressurized molten metal, it can produce super smooth surface on the casting. When the molten metal is forced into the cavity, it fills completely to ensure a smooth surface. Another advantage of die casting is that it can minimize the demand of finishing process. Other types of casting process usually use machine to complete the casting, and the secondary processing operation is time-consuming and troublesome. The good news is that die casting reduces the need for this kind of operation. In many cases, castings can be shipped immediately after completion of the casting process.

Disadvantages Of Die Casting

On the one hand, compared with other casting processes, die castings are expensive, and the cost of purchase and maintenance of casting machine is very high. Even if relatively cheap zinc is used as casting raw material, the cost is also high. Some defects, such as flow marks, water marks, scratches, dents and so on, may also occur in the die casting.

Causes And Prevention Methods Of Common Defects In Die Castings

- However, why there are defects during the process of die casting and how to prevent them.

- Air hole (bubble, choke hole, air pocket)

Blowhole is a kind of hole existing on the surface or inside of the casting, which is round, oval or irregular. Sometimes multiple blowholes form an air mass, and the subcutaneous is generally pear shaped. The shape of choke hole is irregular, and the surface is rough. The air pocket is a concave part in the surface of casting, and the surface is smooth. It can be found by the appearance inspection of the open hole, and it can only be found by the mechanical processing of the subcutaneous pores.

The causes are as follows

- 1. The preheating temperature of the mould is too low and the liquid metal cools too fast when passing through the gating system.

- 2. The mold exhaust design is not good, the gas can not be discharged smoothly.

- 3. The coating is not good, and its exhaust is not good, even it volatilizes or decomposes gas.

- 4. There are holes and pits on the surface of the mold cavity. After the liquid metal is injected, the gas in the holes and pits expands rapidly and compresses the liquid metal to form choking holes.

- 5. The surface of mold cavity is rusted and not cleaned.

- 6. The raw material (sand core) is not properly stored and preheated before use.

- 7. The deoxidizer is not good, or the dosage is not enough or the operation is improper.

Prevention methods:

- 1. The mold should be fully preheated, the particle size of the coating (graphite) should not be too fine, and the air permeability is good.

- 2. The inclined pouring method is used.

- 3. Raw materials should be stored in a well ventilated and dry place and preheated during use.

- 4. The pouring temperature should not be too high.

Shrinkage (porosity)

Shrinkage cavity is a kind of rough surface hole on the surface or inside of casting. Slight shrinkage cavity is a lot of scattered small shrinkage cavities, that is shrinkage porosity, and the grains at the shrinkage cavity or shrinkage porosity are coarse. It often occurs near the ingate, riser root, thick and large parts, wall thickness transition and thick and thin parts with large plane.

The causes are as follows

- 1. The working temperature control of the die does not meet the requirements of directional solidification.

- 2. Improper selection of coating and poor control of coating thickness at different parts.

- 3. The position of the casting in the mold is not designed properly.

- 4. The design of pouring and riser failed to play the role of full feeding.

- 5. Pouring temperature is too low or too high.

Prevention and control methods:

- 1. Increase the temperature of abrasive tools.

- 2. Adjust the thickness of the coating layer, spray the coating evenly, and do not form local coating accumulation when the coating falls off and is repainted.

- 3. The mold is heated locally or insulated locally.

- 4. The hot spot is inlaid with copper block to chill the local part.

- 5.design heat sink on the mold, or accelerate the cooling rate of the local area through water, or spray water outside the mold, spray.

- 6. The demountable chilling blocks are placed in the mold cavity in turn to avoid insufficient cooling of the chilling blocks during continuous production.

- 7. The pressure device is designed on the mold riser.

- 8. The gating system design should be accurate and the suitable pouring temperature should be selected.

Slag Hole (slag inclusion of flux or metal oxide)

Slag hole is a kind of open hole or dark hole on the casting. All or part of the hole is filled with slag. The shape of the hole is irregular. It is difficult to find small spots of flux inclusions. After slag is removed, it presents smooth holes, which are generally distributed in the lower part of the pouring position, near the ingate or the dead corner of the casting. Oxide inclusions are mostly distributed on the surface of the casting near the ingate in a network, sometimes in a thin sheet shape, In the process of fracture, it often breaks from the interlayer, in which oxide is one of the causes of cracks.

The causes are as follows

Slag hole is mainly caused by alloy melting process and pouring process (including incorrect design of pouring system). The mold itself will not cause slag hole, and metal mold is one of the effective methods to avoid slag hole.

Prevention and control methods:

- 1. The gating system is set correctly or cast fiber filter is used.

- 2. Inclined pouring method is adopted.

- 3. Select flux and strictly control quality.

Crack (hot crack, cold crack)

The appearance of the crack is straight or irregular curve. The surface of hot crack fracture is strongly oxidized to dark gray or black, without metallic luster. The surface of cold crack fracture is clean and metallic luster. Generally, the external cracks of castings can be seen directly, while the internal cracks can only be seen by other methods. Cracks are often associated with shrinkage porosity, slag inclusion and other defects, which often occur in the inner side of the casting sharp corner, the junction of thick and thin sections, and the hot spot area where the riser is connected with the casting.

The causes are as follows

Metal mold casting is easy to produce crack defects, because the metal mold itself has no concession, the cooling speed is fast, it is easy to cause the internal stress of the casting to increase, the mold opening is too early or too late, the pouring angle is too small or too large, the coating layer is too thin and so on, which are easy to cause cracks in the mold cavity itself.

Prevention and control methods:

- 1. Attention should be paid to the structural and technological properties of the castings, so that the parts with uneven wall thickness can be evenly transited, and the appropriate fillet size should be adopted.

- 2. Adjust the thickness of the coating to make the parts of the casting reach the required cooling rate as far as possible to avoid forming too much internal stress.

- 3. Attention should be paid to the working temperature of the metal mould, the inclination of the mould should be adjusted, the core should be pulled out timely to crack, and the casting should be taken out for slow cooling.

Cold Insulation (poor fusion)

Cold shut is a kind of through seam or surface crack with round edge, which is separated by oxide skin in the middle and not completely integrated. When cold shut is serious, it becomes “under cast”. Cold shut often appears on the top wall of casting, thin horizontal or vertical plane, thick thin wall connection or thin auxiliary plate.

The causes are as follows

- 1. The exhaust design of metal mould is unreasonable.

- 2. The working temperature is too low.

- 3. Poor coating quality (artificial, material).

- 4. The position of runner is not right.

- 5. The pouring speed is too slow.

Prevention and control methods:

- 1. The runner and exhaust system should be designed correctly.

- 2. For large area thin-walled castings, the coating should not be too thin, and properly thickening the coating layer is conducive to forming.

- 3. Properly raise the working temperature of the die.

- 4. The inclined pouring method is adopted.

- 5. Mechanical vibration metal mold is used for pouring.

Sand Hole (sand hole)

A relatively regular hole is formed on the surface or inside of the casting, and its shape is consistent with the shape of sand particles. When the casting is just out of the mold, the sand particles embedded on the surface of the casting can be seen, from which the sand particles can be taken out. When multiple sand holes exist at the same time, the surface of the casting is orange peel.

The causes are as follows

1. The sand particles falling from the surface of the sand core are wrapped by liquid copper and form holes on the surface of the casting.

- 2. The surface strength of sand core is not good, burnt or not completely solidified.

- 3. The size of the sand core does not match the external mold, and the sand core is crushed when the mold is closed.

- 4. The mold was dipped in graphite water contaminated by sand.

- 5. The sand dropped from the friction between the ladle and the sand core at the runner is washed into the cavity with copper water.

Prevention and control methods:

- 1. Sand core production strictly according to the process, check the quality.

- 2. The size of sand core is consistent with that of outer mold.

- 3. The ink should be cleaned up in time.

- 4. Avoid friction between ladle and sand core.

- 5. Blow out the sand in the mold cavity when setting the sand core.