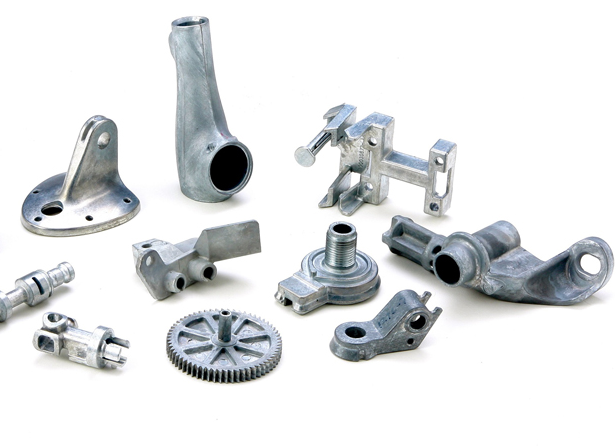

Die-cast zinc is widely used in industrial and consumer applications because of its excellent properties, let’s check out the material properties of die cast zinc and the difference between cast zinc and steel.

What is Die Cast Zinc Material?

Die-cast zinc is a zinc alloy formed through a high-pressure casting process, primarily consists of zinc (Zn) as a matrix, with aluminum (Al), copper (Cu), and magnesium (Mg) added. Like a Transformer, it can be transformed into a variety of complex shapes within the mold, since it exhibits excellent fluidity, wear resistance, and mechanical properties. This material has a low melting point (approximately 380-400°C) and good fluidity, making it particularly suitable for manufacturing small, precision parts. From door handles to automotive parts, die-cast zinc is ubiquitous, earning it the nickname “all-purpose putty” of the metal world. Common die-cast zinc alloy grades include ZA8, ZA12, and ZA27, where the number represents the percentage of aluminum content.

Common die-cast zinc alloys include the following:

- Zinc-Aluminum (Zamak): This is a commonly used zinc alloy composed primarily of zinc, aluminum, copper, and magnesium. It offers excellent strength, toughness, and surface coating properties, making it suitable for manufacturing parts of various complex shapes.

- Zinc-Aluminum-Magnesium (ZAM): This is a relatively new zinc alloy that incorporates aluminum and magnesium to enhance its strength and corrosion resistance. This alloy is widely used in the automotive and aerospace industries.

- Zinc-Copper (Zinc-Copper): This alloy contains a high proportion of copper, which increases its strength and hardness. It is suitable for applications requiring high strength and enhanced electrical conductivity.

- Zinc-Nickel (Zinc-Nickel): This alloy incorporates nickel to enhance its corrosion resistance, resulting in high corrosion and wear resistance. It is commonly used in the manufacture of parts for the automotive and aerospace industries.

The above are some common die-cast zinc alloys. The specific alloy composition and properties can be adjusted according to specific application requirements. Selecting the appropriate zinc alloy can meet the engineering requirements of various fields.

Zinc Die Cast Composition

- Zinc: Over 90% of the material, the main component

- Aluminum: Approximately 4%, improves fluidity and strength

- Copper: 1-3%, enhances hardness and wear resistance

- Magnesium: A trace amount prevents intergranular corrosion

The optimal balance of these elements ensures die-cast zinc maintains excellent casting properties while maintaining sufficient mechanical strength.

Die Cast Zinc Material Properties

Die cast zinc is a metal alloy that is commonly used in the manufacturing of various metal components due to its desirable properties. Here are some of the key material properties of die cast zinc:

1. High strength: Die cast zinc has high strength and stiffness, making it suitable for use in applications that require high durability and resistance to deformation.

2. Excellent dimensional stability: Zinc has a low thermal expansion, which means it maintains its dimensional stability even when exposed to changes in temperature and humidity. This makes it ideal for applications that require tight tolerances and precise dimensions.

3. Good corrosion resistance: Zinc has good resistance to corrosion, which makes it suitable for use in applications that are exposed to harsh environments or corrosive substances.

4. Good thermal conductivity: Die cast zinc has good thermal conductivity, which allows it to dissipate heat quickly. This, combined with its high strength, makes it ideal for use in heat sinks and other thermal management applications.

5. Good surface finish: Die cast zinc has a smooth surface finish that can be easily painted or plated, making it versatile for a variety of applications.

6. Lightweight: Zinc has a low specific gravity, which means it is lightweight compared to other metals like steel and brass. This makes it ideal for applications that require strength but need to minimize weight.

Is Die Cast Zinc Magnetic?

Die cast zinc is not magnetic as it is a non-ferrous metal alloy. Magnetic materials are those that contain iron or other ferromagnetic materials, which can be attracted to a magnet. Zinc, on the other hand, is a non-magnetic metal alloy that does not contain iron or other ferromagnetic materials. Therefore, die cast zinc is not attracted to a magnet and is not considered to be a magnetic material. However, it is important to note that if any other magnetic material is present in or on the zinc component, such as steel fasteners or magnetic coatings, then the overall component may exhibit magnetic properties.

Is Die Cast Zinc Corrosion Resistant?

Die cast zinc has good corrosion resistance, especially in comparison to other non-ferrous metals. Zinc forms a naturally occurring protective layer of zinc oxide when exposed to air, which helps to prevent it from further corrosion. Additionally, zinc coatings can further enhance the corrosion resistance of die cast zinc parts. However, it is important to note that zinc is still subject to certain types of corrosion, such as galvanic corrosion when it comes in contact with other metals, or exposure to highly corrosive environments. In situations where the die cast zinc parts will be used in harsh environments or exposed to corrosive substances, additional protection may be necessary to maintain their corrosion resistance. To enhance the corrosion resistance of die cast zinc parts, different surface treatments can be applied, such as protective coatings like chromate or phosphate and anodizing. These coating types increase resistance to corrosion and provide an additional layer of protection.

Die Cast Zinc Material Types & Grades (Composition, Properties, Uses)

| Grade | Main Composition (wt%) | Key Mechanical Properties | Main Properties & Features | Typical Uses |

|---|---|---|---|---|

| ZAMAK 2 (ZA-2) | Al: 3.9–4.3, Cu: 2.7–3.3, Mg: 0.035–0.06, Zn: balance | Tensile: 359 MPa <br> Impact: 48 J <br> Elongation: 7% <br> Hardness: 100 HB <br> Fatigue: 317 MPa | Highest strength among ZAMAK alloys, best creep resistance, good corrosion resistance | Automotive transmissions, gears, electronic connectors, bearings |

| ZAMAK 3 (ZA-3) | Al: 3.9–4.3, Cu: ≤0.03, Mg: 0.04–0.06, Zn: balance | Tensile: 283 MPa <br> Impact: 58 J <br> Elongation: 10% <br> Hardness: 82 HB <br> Fatigue: 214 MPa | Excellent castability, good ductility, dimensional stability | Locks, gears, toys, meter housings, small hardware |

| ZAMAK 4 (ZA-4) | Al: 3.9–4.3, Cu: 0.3–0.4, Mg: 0.04–0.06, Zn: balance | Tensile: 317 MPa <br> Impact: 61 J <br> Elongation: 10% <br> Hardness: 92 HB <br> Fatigue: 214–262 MPa | Improved ductility and strength, good plating performance | European market applications, general mechanical parts |

| ZAMAK 5 (ZA-5) | Al: 3.9–4.3, Cu: 0.75–1.25, Mg: 0.04–0.06, Zn: balance | Tensile: 328 MPa <br> Impact: 65 J <br> Elongation: 7% <br> Hardness: 91 HB <br> Fatigue: 262 MPa | Higher strength and hardness than ZAMAK 3, good mechanical properties | Automotive housings, lamp bases, bicycle and auto transmission parts |

| ZAMAK 7 (ZA-7) | Al: 3.8–4.3, Cu: ≤0.001, Mg: 0.04–0.06, Zn: balance | Tensile: 290 MPa <br> Impact: 60 J <br> Elongation: 13% <br> Hardness: 80 HB <br> Fatigue: 200 MPa | High fluidity, best for thin-wall castings, improved ductility | Thin-walled or intricate electronic and communication components |

| ZAMAK 8 (ZA-8) | Al: 8.0–8.8, Cu: 1.8–2.2, Mg: 0.02–0.03, Zn: balance | Tensile: 374 MPa <br> Impact: 42 J <br> Elongation: 1–6% <br> Hardness: 95–110 HB <br> Fatigue: 275 MPa | Higher strength, good for thinner and complex castings | Automotive parts, industrial equipment, building hardware |

| ZAMAK 12 (ZA-12) | Al: 10.5–11.5, Cu: 0.5–1.3, Mg: 0.01–0.02, Zn: balance | Tensile: 400 MPa <br> Impact: 29 J <br> Elongation: 1–3% <br> Hardness: 95–115 HB <br> Fatigue: 296 MPa | Very high strength and hardness, for high-load parts | Pump bodies, gears, pressure housings |

| ZAMAK 27 (ZA-27) | Al: 25–28, Cu: 2.0–2.5, Mg: 0.01–0.02, Zn: balance | Tensile: 386–410 MPa <br> Impact: 10 J (lower than other ZA alloys) <br> Elongation: 1–2% <br> Hardness: 120–130 HB <br> Fatigue: 320 MPa | Extremely high strength and hardness, lower ductility, excellent wear resistance | High-load gears, heavy-duty bearings, oil pumps, industrial/agricultural machinery |

Die Cast Zinc vs Steel, What’s the Difference?

Die cast zinc and steel are two different materials with different properties and characteristics. Here is a comparison of some key differences between die cast zinc and steel:

1. Strength: Steel is generally stronger and more rigid than die cast zinc, making it ideal for applications that require high strength and durability.

2. Density: Steel is denser than die cast zinc, which means it is heavier in weight compared to an equal volume or size of die cast zinc.

3. Corrosion resistance: Steel is prone to corrosion, especially in high-moisture or harsh environmental conditions, whereas die cast zinc has good corrosion resistance.

4. Machinability: Steel is easier to machine and grind compared to die cast zinc, which can be more challenging to work with due to its lower melting point and lower hardness.

5. Cost: Die cast zinc is generally less expensive than steel due to its lower density, lower melting point, and lower processing costs.

6. Surface finish: Die cast zinc has a smoother surface finish than some types of steel, which can make it more aesthetically pleasing in applications that require a smooth and polished appearance.