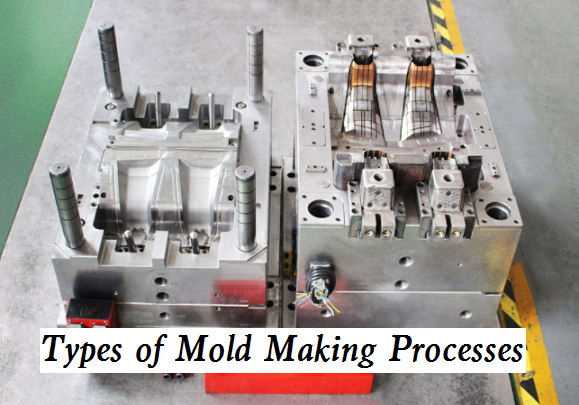

Modern mold making has a wide variety of techniques to choose from, what is the most commonly used in the mold manufacturing industry? Whether for plastic injection mold or metal mold, let’s take a look at some popular types of mold making methods with principles, equipment, characteristics, and uses.

Common Types of Mold Making Processes & Methods - Mold Manufacturing Techniques

1. EDM

(1) Principle

Electrical discharge machining, or EDM for short, is a special machining method that uses the electric erosion generated by the pulse discharge between the two poles immersed in the working fluid to etch away the conductive materials, also known as discharge machining or electric etching machining. EDM is suitable for machining complex parts such as precision small cavities, narrow slots, grooves, and corners. When it is difficult for the tool to reach the complex surface, EDM is better than milling in the places where deep cutting is needed and where the aspect ratio is particularly high. For the machining of high-tech parts, the re-discharge of the milling electrode can improve the success rate. Compared with the high and expensive tool cost, EDM is more suitable.

(2) Equipment: EDM machine tool.

(3) Characteristics

Capable of machining materials and workpieces with complex shapes that are difficult to cut by ordinary cutting methods; No cutting force during machining; No burr, knife mark, groove, and other defects; The tool electrode material need not be harder than the workpiece material; Direct use of electric energy processing, easy to realize automation; After processing, the surface has a metamorphic layer, which must be further removed in some applications; The purification of working fluid and the treatment of smoke pollution produced in the processing are more troublesome. It can process any conductive material with high strength, high hardness, high toughness, high brittleness, and high purity; There is no obvious mechanical force during processing, which is suitable for the processing of low stiffness workpieces and microstructures: the pulse parameters can be adjusted according to needs, and rough machining, semi-finishing machining, and finishing machining can be carried out on the same machine tool; The pits on the surface after EDM are conducive to oil storage and noise reduction; The production efficiency is lower than that of cutting; Part of the energy in the discharge process is consumed on the tool electrode, resulting in electrode loss and affecting the forming accuracy.

(4) Uses

Machining molds and parts with complex-shaped holes and cavities; Processing all kinds of hard and brittle materials, such as cemented carbide and quenched steel; Processing deep and fine holes, special-shaped holes, deep grooves, narrow seams, and cutting sheets; Process all kinds of forming tools, templates, thread ring gauges and other tools and measuring tools.

2. WEDM

(1) Principle

Wire cut electrical discharge machining, referred to as WEDM, also known as wire cutting, uses the continuously moving fine metal wire (called electrode wire) as the electrode to etch the metal and cut the workpiece by pulse spark discharge.

(2) Equipment: WEDM machine tool.

(3) Characteristics

In addition to the basic characteristics of EDM, WEDM has some other characteristics:

– Any two-dimensional curved surface with a straight line as the generatrix can be machined without manufacturing complex tool electrodes;

– Can cut about 0.05mm narrow seam;

– All the surplus materials are not processed into scrap during processing, which improves the utilization rate of energy and materials;

– In the low-speed WEDM with non-recycling electrode wires, the continuous renewal of electrode wires is conducive to improving the machining accuracy and reducing the surface roughness;

(4) Uses

Mainly used for processing: various complex and precise workpieces, such as punch, die, punch and die, fixed plate, discharge plate, etc. Forming tools, templates, and metal electrodes for EDM. Various micro holes, slots, narrow slots, arbitrary curves, etc. It has the outstanding advantages of small machining allowance, high machining precision, short production cycle, and low manufacturing cost.

3. Electro-Chemical Machining

(1) Principle

Based on the principle of anodic dissolution in the electrolytic process and with the help of the formed cathode, a process method of machining and forming the workpiece according to a certain shape and size is called electrochemical machining.

(2) Uses

ECM has significant advantages in machining difficult materials, complex shapes, or thin-walled parts. Electrochemical machining has been widely used, such as gun barrel rifling, blade, integral impeller, die casting mold, special-shaped hole, and special-shaped parts, chamfering and deburring. And in the processing of many parts, ECM technology has occupied an important or even irreplaceable position.

(3) Advantages

Wide processing range. Electrochemical machining can process almost all conductive materials and is not limited by the mechanical and physical properties such as strength, hardness, and toughness of the materials. The metallographic structure of the processed materials basically does not change. It is commonly used to process hard machining materials such as cemented carbide, superalloy, quenched steel, and stainless steel.

(4) Limitations

The machining accuracy and stability are not high; The processing cost is higher, and the smaller the batch, the higher the additional cost of a single piece.

4. Ion Beam Machining

(1) Principle

Ion beam processing is realized by accelerating and focusing the ion flow generated by the ion source to the workpiece surface under a vacuum.

(2) Characteristics

Because the ion current density and ion energy can be accurately controlled, the machining effect can be accurately controlled to realize ultra-precision machining at the nano level, even at the molecular and atomic levels. During ion beam processing, the pollution is small, the processing stress and deformation are very small, and the adaptability to the processed materials is strong, but the processing cost is high.

(3) Uses

Ion beam processing can be divided into etching and coating according to its purpose.

5. Chemical Etching

(1) Principle

Chemical etching is a special processing of workpieces that uses the corrosion and dissolution of acid, alkali, or salt solution on workpiece materials to obtain the required shape, size, or surface state.

(2) Characteristics

– It can process any metal materials that can be cut, and is not limited by hardness, strength, and other properties;

– Suitable for large-area processing, and can process multiple pieces at the same time;

– Easy to operate;

– Not suitable for processing narrow slots and holes;

– Defects such as uneven surfaces and scratches should not be eliminated. Source: if there is an infringement on the network, please inform us to delete it

(3) Use

Suitable for large area thickness thinning processing; It is suitable for machining complex holes on thin-walled parts.