When selecting die-casting materials, mechanical engineers should reasonably select the correct die-casting materials according to various factors such as the function performance, process performance, production conditions, economy, and the characteristics of die-casting materials. Common die casting materials for mechanical parts include aluminum alloy, zinc alloy, and magnesium alloy. Aluminum alloy is the most widely used die casting material at present. It is widely used in the automobile industry, motorcycle industry, aerospace, and so on.

The characteristics of aluminum alloy are as follows:

1. The density of aluminum alloy is small, which is only about 1 / 3 of that of iron, copper and zinc. Its outstanding advantages are high specific strength and specific stiffness.

2. Aluminum alloy has good electrical and thermal conductivity.

3. Aluminum alloy has good oxidation and corrosion resistance. In the air, a dense layer of sulfur trioxide oxide film is easily formed on the surface of aluminum, which can prevent further oxidation.

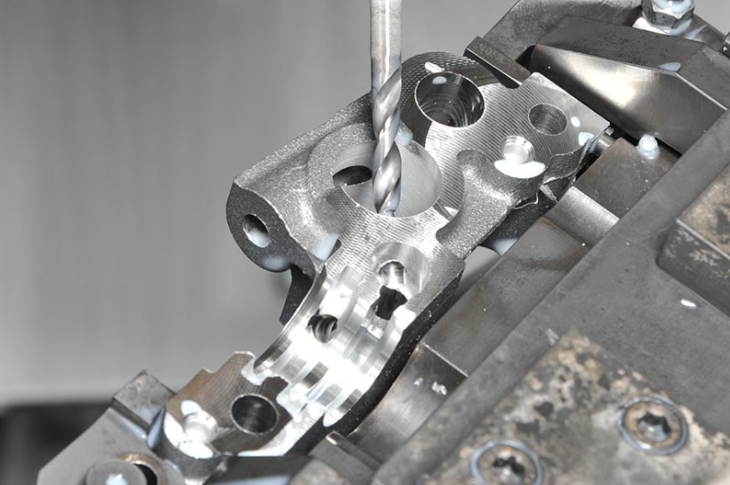

4. Aluminum alloy has good die casting performance. Aluminum alloy die casting has the advantages of simple process, good forming and cutting performance, high mechanical properties and corrosion resistance. It is the most potential alloy to replace steel castings.

5. Aluminum alloy has good mechanical properties at high temperature and also maintains good mechanical properties when working at low temperature.

6. The disadvantage of aluminum alloy is that it is easy to produce large concentrated shrinkage cavities at the final solidification. In addition, aluminum alloy has a strong affinity with iron and is easy to stick to the mold. It should be pressed on the cold chamber die casting machine.

Zinc alloy is also common. The characteristics of zinc alloy are as follows:

1.Zinc alloy has excellent casting properties, mechanical properties and toughness. It is widely used in traditional mechanical parts, hardware, locks, toys and other industries. Zinc alloy has excellent electrical and thermal conductivity, good vibration damping characteristics and good electromagnetic shielding performance. Its application in electronics, telecommunications and household appliances is growing.

2. Zinc alloy is a universal, reliable and low-cost material, which is easy to die-casting production. Zinc alloy has good die-casting performance, so it is easier to die-casting products with complex shapes, thin wall,s and high dimensional accuracy. Due to the thin-wall casting performance of zinc alloy, the requirements of product lightweight and cost reduction can be realized.

3. Compared with aluminum alloy and magnesium alloy, zinc alloy has higher tensile strength, yield strength, impact toughness, hardness and better elongation.

4. The surface of zinc alloy die castings is very smooth and can be used directly without surface treatment. At the same time, it is also easier to carry out various surface treatments, such as polishing, electroplating, spraying, etc., in order to obtain better surface quality.

5. Zinc alloy has a low melting point and melts at 385 ℃. Compared with aluminum alloy and magnesium alloy, zinc alloy is the easiest to die cast.

6. Poor corrosion resistance. When the impurity elements lead, cadmium, and tin in the composition of zinc alloy exceed the standard, they will gradually age and deform, which is manifested in volume expansion, a significant decline in mechanical properties (especially plasticity), and rupture after a long time.

7. Timeliness. If the service time is too long, the shape and size of zinc alloy die castings will change slightly.

8. Zinc alloy should not be used in high-temperature and low-temperature working environments. Zinc alloy has good mechanical properties at room temperature, but the tensile strength and impact properties at high temperature and low temperature are significantly reduced. Zinc alloy is easy to age, which is the main reason why the application range of zinc alloy is limited. The working temperature range of zinc alloy is narrow. When the temperature is lower than – 10 ℃, its impact toughness decreases sharply. When the temperature increases, the mechanical properties decrease, and creep is easy occurs. Therefore, the temperature of stressed parts generally does not exceed Look. Strictly controlling the purity of zinc alloy raw materials and the smelting process, adding a small amount of Mg and an appropriate amount of Cu to zinc alloy can reduce or eliminate aging and improve cutting performance.

Another kind is magnesium alloy. The characteristics of magnesium alloy are as follows:

1. Magnesium alloy is known as the “green engineering material of the 21st century”. Its density is 2 / 3 of aluminum alloy and 1 / 4 of steel, but its specific strength and specific stiffness are better than aluminum alloy and steel, far higher than engineering plastics. It is an excellent and lightweight structural material.

2. Magnesium alloy has good energy absorption and vibration absorption characteristics. When used in a product shell, it can reduce noise transmission, and when used in moving parts, it can absorb vibration and prolong the service life of parts.

3. It has good electromagnetic shielding and can provide the anti-electromagnetic radiation of electronic products.

4. Good rigidity and impact resistance.

5. Good ductility and easy to form, which can make the product design flexible and improve the product grade.

6. Magnesium alloy has a low melting point, small deformation at low temperature, and high dimensional accuracy, which is conducive to one-time die opening forming; The affinity with iron is small, and the adhesion to the mold is small, which is conducive to improving productivity and mold life; moreover, the good flow performance of magnesium alloy is conducive to the production of complex and small parts.

7. The cutting tool has the best cutting performance, long cutting force, and cutting effect.

8. Good heat dissipation, second only to aluminum alloy.

9. The size stability is good, and the change in ambient temperature and time has little effect on the size.

10. 100% regeneration.

11. Magnesium alloy is easy to oxidize in air. After forming, magnesium alloy die castings must undergo surface treatment to improve corrosion resistance and surface quality of parts. Common surface treatment methods include electroplating, spraying, anodizing, etc. Similarly, magnesium alloys have the disadvantages of high-temperature brittleness and hot cracking tendency.

Common problems and solutions:

1. Hammerhead stuck

In order to avoid hammerhead jamming, we can start from two aspects: 1. In production, we often measure the temperature to avoid the hammerhead jamming caused by the high temperature of the hammerhead and the driver barrel; 2. For the use of materials, high-quality alloy materials should be selected to avoid the infiltration of impurities. When putting back materials, attention should also be paid not to allow impurities to mix in, so as to avoid impurities adhering to the hammerhead and causing the hammerhead to get stuck.

2. The injection head is stuck on the gooseneck

When the hammerhead is stuck, first wait until the equipment is at normal temperature and try to rotate the hammer head. If it doesn’t work, change the cylinder to solve the problem and take out the hammerhead. If you want to quickly solve the problem of jamming, the fastest way is to replace the charging port.

3. When the die-casting machine hits the material, it often happens that the material cannot be hit after dozens of molds. It often takes a few minutes to hit the material

Generally, in this case, the nozzle head or nozzle body should be blocked. At this time, observe whether there is no bright spot at the top of the blanking head. If it is all gray, it means that the nozzle is blocked. The solutions are as follows: 1. Adjust the nozzle temperature to be higher; 2. Turn off the nozzle and reduce the time by 0.1 to 0.2 seconds; 3. Turn down the fixed mold cooling water slightly.

4. Easy to crack when casting thin-walled parts

It can be analyzed from the following points: There may be problems with the materials. For the use of die-casting materials, try to control the proportion of waste materials to no more than 30%; The opening of the mold is not good. First, the jacking force is unbalanced; Second, the unreasonable opening of cooling water leads to uneven mold temperature, and the filling flow is only unreasonable. Improper selection of process parameters. The main problems of process parameters are errors in magic retention time and ejection delay time. The mold retention time should not belong, about 3S per mm wall thickness; The ejection delay cannot belong, generally 0.5-2s.

5. Feedback of adc14 material during die casting processing that the material is too hard and easy to wear the tool

To solve this problem, we can see the following points: The most important thing is that there are no impurities in the components of Kailai Oh, that is to say, hardpoints. It is best to mix them all with new raw materials instead of recycled materials, especially since the quality of the S1 element is better; The gem blade specially produced for these relatively hard alloys should be used, with a general service life of about 7 days.

6. Wonder why some aluminum die castings have black spots when polished?

There are several reasons: silicon oxide or aluminum oxide ingot may solve the problem. But the biggest possibility comes from the release agent, spraying too much release agent or the organic content of release agent is too high. At the temperature of hot-melt aluminum, some of these organics are reduced to carbon and some become organic macromolecular polymers. Carbon molecules and polymers are mixed, and when aluminum castings are formed, they are contained in the surface layer, which becomes the black spots we see. Therefore, reduce the concentration of the spraying agent and use other spraying agents; Or extend the blowing time after spraying.

7. Metal splashing sometimes occurs during die casting

Why does metal splash sometimes occur? There may be several reasons: the clamping between moving and fixed molds is not tight, and the gap between them is large; Or insufficient clamping force causes metal splashing, Or it is caused by die-casting motorization and nonparallel installation of fixed die; Or the span of the supporting plate is large, and the compression force causes the deformation of the sleeve plate, resulting in spraying. In case of the above reasons, the splash can be solved through the following debugging: reinstall the die; Increase the mold locking force: adjust the die casting machine to keep the moving and fixed mold mounting plates parallel to each other; The support plate is added on the moving die to increase the stiffness of the sleeve plate.

8. Why can’t the hole processing of aluminum die casting exceed 0.25mm?

In order to be suitable for die casting, people add a lot of silicon into the aluminum alloy for die casting. When the aluminum alloy condenses in the mold, the silicon will float to the surface and form a layer of silicon film. The hardness is very hard and wear-resistant. Some OEM designers use this feature to directly design the inner surface of the die casting hole as the bearing surface. This silicon surface layer is generally only 0.2 to 0.9mm thick. If you process too much, the bearing surface will be shortened.

9. What are the reasons for the pattern of die castings after anodizing?

At present, the spraying and pressure spraying oil is mainly distributed unevenly and gathered locally, resulting in the abnormal composition of aluminum alloy on the surface or cold septum spots, so there is the phenomenon of the pattern after oxidation; The pattern of oxidation pattern is basically the same as that on die casting. Because the high-speed switching position is not appropriate, resulting in undercasting, there will be patterns after oxidation. Textbooks say that the copper ion content in the oxidation tank is too high, which also produces patterns, but this situation is very rare.

10. Die casting die sticking

What if the die-casting die sticks? First, check whether the mold temperature is normal and appropriately reduce the pouring temperature of alloy liquid and mold temperature; Check whether the proportion of release agent is abnormal, try to replace the release agent, debug the surface of the spraying position for polishing, and carefully polish the nitrided mold to prevent damaging the nitrided layer on the surface and forming the situation of more polishing and more sticking; Improve the design structure of gating system to avoid continuous scouring of cavity wall or core by alloy liquid; Modify the mold cooling system; Adjust the die casting process parameters, appropriately reduce the injection speed and shorten the two speed stroke.