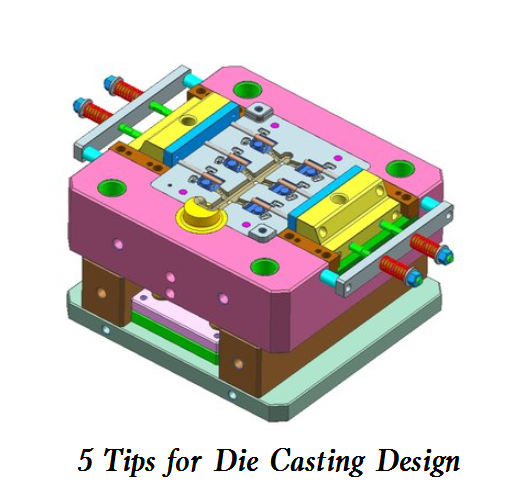

The design of die casting parts is an important sector of die casting technology. The selection of mold parting surface, the opening of the gate, the shrinkage of castings, the dimensional accuracy of castings, and more should be considered during the design phase. Below let’s take a look at 5 things to consider in die casting design.

5 Things to Consider in Die Casting Design: Wall Thickness, Ribs, Fillet, and More

1. Shape and structure of die castings

A reasonable die casting structure can not only simplify the structure of the die casting mold, reduce the manufacturing cost, but also improve the casting quality

– Elimination of internal side recesses

– Avoid or reduce the core pulling position

– Avoid core crossing

2. Wall thickness of die castings

The wall thickness of die castings (usually referred to as wall thickness) is a factor with special significance in the die casting process. The wall thickness is closely related to the entire process specification, such as the calculation of filling time, the selection of ingate speed, the calculation of solidification time, the analysis of mold temperature gradient, the role of pressure (final specific pressure), the length of mold retention time, the height of casting ejection temperature and the operating efficiency

– If the wall thickness of the part is too thick, the mechanical properties of the die casting will be significantly reduced. The thin-walled casting has good compactness, and the strength and pressure resistance of the casting is relatively improved

– The wall thickness of the casting should not be too thin, which will lead to poor filling of aluminum liquid, forming difficulties, the poor fusion of aluminum alloy, cold shut and other defects on the surface of the casting, and bring difficulties to the die casting process

– With the increase of the wall thickness of the die casting, its internal defects such as air holes and shrinkage cavities increase. Therefore, on the premise of ensuring that the casting has sufficient strength and stiffness, the wall thickness of the casting should be reduced as much as possible and the thickness of the section should be uniform. In order to avoid defects such as shrinkage, the thickness of the thick wall of the casting should be reduced (material reduction) and the ribs should be added

– For large area thick wall castings, set ribs to reduce the casting wall thickness

3. Ribs of die casting design

Ribs are used to improve the strength and rigidity of parts, prevent shrinkage deformation of castings, and prevent deformation of workpieces when ejecting from the mold after the wall thickness is thinned. They are used to act as auxiliary circuits (metal flow paths) when filling. The thickness of die casting ribs should be less than the thickness of the wall, generally taking 2/3~3/4 of the thickness there

4. Fillet of die casting design

All wall-to-wall connections on die castings, regardless of right angle, acute angle, or obtuse angle, the root of blind hole and groove, shall be designed as rounded corners. Only when it is expected to be determined as the parting surface, rounded corners are not used. The rest of the parts must be rounded corners generally. The rounded corners should not be too large or too small. Too small die castings are prone to crack and too large die castings are prone to loose shrinkage. The rounded corners of die castings are generally taken as 1/2 wall thickness ≤ R ≤ wall thickness The function of fillets is to help the metal flow, reduce eddy current or turbulence, and avoid cracking due to stress concentration caused by the existence of fillets on parts When the parts are to be plated or coated, the fillets can obtain uniform coating to prevent deposition at the sharp corners, which can extend the service life of the die casting mold and prevent corner collapse or cracking due to the existence of the sharp corners of the mold cavity

5. Draft angle of die casting design

The function of the draft angle is to reduce the friction between the casting and the mold cavity so that the casting can be easily taken out; Ensure that the casting surface is not strained. To prolong the service life of the die casting dies, the minimum casting draft angle of aluminum alloy die castings is generally two degrees per side.