Casting mold is the main factor of die-casting production. The so-called die-casting process is to cast molten aluminum in a pressure die-casting machine. Castings can make various complex shapes, so as to stably, rhythmically, and efficiently produce qualified castings with good appearance, internal quality, size in line with the requirements of drawings or agreements, and even high-quality castings.

Aluminum die casting mold is a large category of mold. With the rapid development of the automobile and motorcycle industry, the die casting industry has ushered in a new period of development. At the same time, it also puts forward higher requirements for the comprehensive mechanical properties and service life of die casting die.

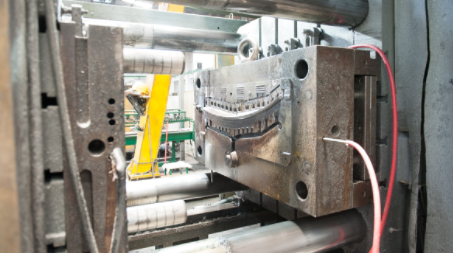

Various surface treatment technologies must be applied to the surface treatment of die-casting molds in order to meet the requirements of high efficiency, high precision, and high service life of die-casting molds. In all kinds of molds, the working conditions of die-casting molds are harsher. Pressure casting is to make the molten metal fill the mold cavity under high pressure and high speed and die-casting, and repeatedly contact with the hot metal in the working process. Therefore, the die-casting mold is required to have high heat fatigue, thermal conductivity, wear resistance, corrosion resistance, impact toughness, red hardness, good demoulding performance, etc. Therefore, the surface treatment technology of die-casting die has high requirements.

5 Reasons Why You Should Choose Junying

In the process of customization of aluminum alloy die castings, you will always encounter various large and small problems. Therefore, when looking for cooperation with an aluminum alloy die-casting factory, you must make a comprehensive investigation. Junying Metal Manufacturing Company Limited has these five advantages, which can help you solve various customization problems in the process of die casting production!

1. With years of experience in aluminum alloy die casting customization, a separate mold room is set up, equipped with various accurate mold-making equipment and an experienced mold-making team. Careful mold making not only has high mold progress and long service life but also lays a foundation for product die casting production.

2. Focusing on the customization mode of medium and high-level surface treatment die castings, the Junying Aluminum alloy die casting factory has always focused on the processing and customization of medium and high-level consumer electronic products. It has rich die-casting experience in various surface treatments of aluminum alloy die castings and also has its own surface treatment department with full materials to ensure the stability of product quality.

3. With 200 die-casting production teams and more than 50 die-casting technicians who have been engaged in die-casting for more than 10 years, we can fully ensure the product quality of orderly production of die-casting products.

4. Diecastingmould.com die casting has passed ISO9001 international management system certification, which can not only ensure product quality but also ensure the stability of product delivery date.

5. The “three major services” system guarantees the work. There is professional project follow-up before sales, and special personnel will follow up the project progress during sales to timely report the product production. The after-sales team has a 24-hour timely response to quickly help customers solve various difficulties and complications after-sales so that customers can choose Diecastingmould.com die casting cooperation more worry-free!