Metal Electrophoresis Finishing Services – Junying Color EPD Surface Treatment for Metal Castings

The color EPD surface treatment is a suitable for applying different colors on metal materials and products. As a one-stop die casting company, Junying is offering Color Electrophoresis Metal Finishing Services for aluminum alloy die castings, zinc alloy die casting parts, and other metal products. We can customize a wide range of electrophoresis colors based on your requirements, achieve high corrosion resistance and good protection. With nearly 20 years of experience on CNC manufacturing, mold making and castings production, not only we can produce custom metal casting supplies in complex shapes with high accuracy and affordable prices, but also provide high-quality surface treatment like electrophoresis services to improve the appearance and properties of your aluminum casting products. Fast delivery within a week, welcome to send your files or needs to us, free quotes will be send back as soon as possible.

Why Choose Our Electrophoresis Surface Treatment

- Widely applied on aluminum castings, lock parts and high-grade furniture hardware

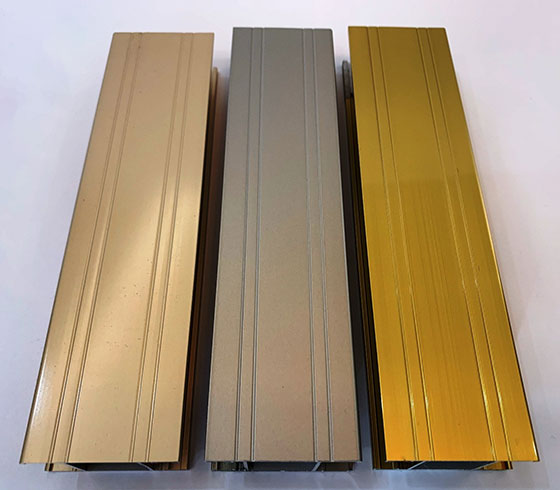

- Uniform and plump coatings available in a variety of color options

- Maintain metallic luster and enhance the corrosion resistance of part surface

- Least influence on the product precision and dimensional stability

- Can be combined with other surface treatment at Junying

- Skilled in the production of metal castings and casting mold, as well as customized finishing

Details of Our Color Electrophoresis Services

| Material | aluminum alloy Al-Cu4Ti, A-U5GT, AICu4Ti(3.1841), A380, etc. |

| Colors | red, purple, green, silver, blue, black, yellow, etc. |

| Process | colour electrophoresis |

| Application | apply different colors on die castings |

| Industries | automotive parts, motorcycle parts, architectural profiles, musical instruments, pens, doors and windows, furniture hardware, lighting parts, lock parts, etc. |

What is Electrophoresis (EPD)?

Electrophoretic deposition (EPD) including a range of industrial processes like electrocoating, cathodic electrodeposition, anodic electrodeposition, and electrophoretic coating, or electrophoretic painting. The electrophoretic coating is analogous to electroplating in that a voltage is applied across electrodes in a bath, the electrode coated is usually the anode. In the EPD process, the colloidal particles suspended in a liquid medium will migrate and deposit onto an electrodeC due to the impact of an electric field, so all colloidal particles that can form stable suspensions and that can carry a charge can be used in electrophoretic deposition, including metals, polymers, ceramics, dyes and more materials. The electrophoresis surface treatment can apply materials to any electrically conductive surface.

Advantages of Electrophoresis Metal Finishing

- The electrophoresis paint film is plump, uniform, flat and smooth

- Outstanding hardness, adhesion, corrosion, impact performance and permeability

- Strong coating and good slippery feeling

- Long-lasting bright color and high durability

- Strong bonding force and penetration

- Good discoloration resistance, impact resistance and anti-corrosion performance