Pad Printing Service

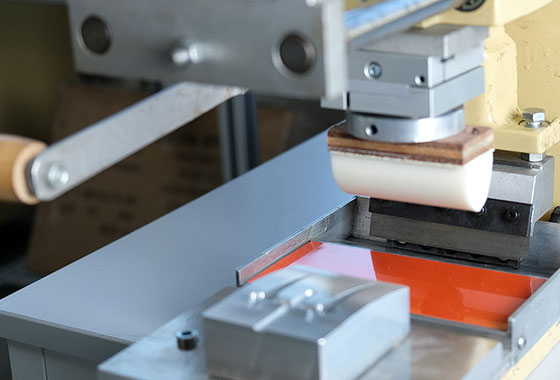

Pad printing is one of the special printing methodsto transfer the color and image that you wanted on surfaces. The process of pad printing is the most versatile of all printing processes with its unique ability to images and text on to three-dimensional, complex surfaces. Using steel (or copper, thermoplastic plastic) gravure, using a curved surface pad printing head made of silicone rubber material, dip the ink on the gravure onto the surface of the pad printing head, and then press on the surface of the desired object to print patterns. For example, the text and patterns on the surface of mobile phones are printed in this way,and the surface printing of many electronic products, such as computer keyboards, instruments and meters, are all printed by pad printing. You can also choose pad printing method to print logo on your die casting parts. The theory behind the pad printing process evolved from the screen, rubber stamp and photogravure printing processes.

China Pad Printing Service Manufacturer, Supplier, Company

China die casting company Junying is dedicated to delivering one-stop services – Pad Printing Surface Treatment Service from design to assembly, create high quality production-like prototypes to high volume production line. Applied in commodity, toys, stationery, electric appliances. From our printing service, you will get a customized surface with single color pad printing & multi-color pad printing. Materials handled include plastic, metal, aluminium & zinc alloy. Pad printing for die casting parts can be done flat, oval, round, concave, convex, irregular & raised shapes.

Junying is your best resource for quality die casting surface finishing. Our high-volume, rapid throughput capabilities allow us to quickly deliver flawless, expertly finished prototypes and high-volume production parts that meet the specific needs of a wide range of industrial applications. Once you are ready to start your new project, please feel free to contact with us for a free quote. Junying is happy to finish your die cast metal products with the Pad Printing that is most appropriate to your goals.

Benefits Of Pad Printing Surface Treatment Service:

- Print onto complex geometries with ease.

- Cost effective for both small and large scale runs.

- Improved traceability – be able to track parts in the field and identify batch/lot number.

- It is possible to print all kind of difficult shaped die casting products such as curved (convex), hollow (concave), cylindrical, spherical, compound angles, textures, etc.

- From printing on three-dimensional plastic parts to embossed or etched surfaces or even die casting parts, pad printing can be used for a wide variety of applications.