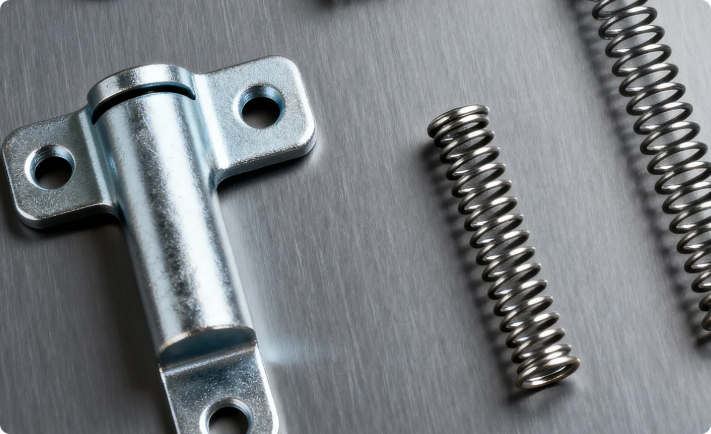

A lock part is any individual component within a locking mechanism or system that works together with other pieces to secure, fasten, or restrict movement until the correct key, code, or action is applied; for example, in a door lock, key cylinders, pins, and bolts are considered lock parts, while in machinery, lock parts may include locking pins, washers, or clips that prevent unwanted loosening or movement, meaning the term generally refers to the essential elements that make a lock function properly and provide security or stability.

- Our Services

- Aluminum Die Casting

- Zinc Die Casting

- CNC Machining Services

- Products

- Die Casting Cable Clamps

- Die Casting Lamp Shade

- Die Casting Lock Parts

- OEM Die Casting Parts

- Contact Us

- Phone: +86 769 8289 0830

- Email: [email protected]

-

Address: #3, Changfu Road, Ludong, Humen, Dongguan, Guangdong, 523935, P. R. China.

What is Lock Part?

What are Lock Part Advantages?

The advantages of lock parts lie in the role they play in both security and stability: they provide reliable protection by preventing unauthorized access or accidental operation, ensure safety by keeping mechanisms firmly in place, improve durability by reducing wear and loosening of components, offer versatility since lock parts come in many types (bolts, pins, washers, clips) for different applications, and allow for easy maintenance and replacement because individual lock parts can often be swapped without needing to change the entire system—making them both practical and cost-effective.

What are Lock Part Applications?

Lock part applications cover a wide range of industries and uses. In door and padlock systems, lock parts like cylinders, bolts, and pins secure buildings, cabinets, and safes. In automotive and aerospace, lock parts such as locking clips, pins, and fasteners keep mechanical assemblies stable under vibration. In machinery and manufacturing, lock washers, nuts, and tabs prevent loosening of parts in rotating or high-stress equipment. In electronics and IT, lock parts can refer to locking connectors or mechanisms that secure data ports. Even in everyday products like luggage, furniture, and bicycles, lock parts provide safety, stability, and theft prevention, making them essential across security, mechanical, and consumer applications.

Advantages of Buying Die Casting Lock Parts on Junying

High-Quality Materials

Lock parts are made from strong alloys such as aluminum and die-cast zinc, ensuring durability, corrosion resistance, and long service life.

Customizable & Aesthetic

Aluminum and zinc alloys allow color modification and surface finishing, giving flexibility for both functionality and appearance.

Experienced Manufacturer

With over 10 years of professional die-casting experience, the company has proven expertise in producing precision lock parts.

Cost-Effective Production

Efficient manufacturing processes provide competitive pricing without compromising quality. Process of Die Casting Lock Parts on Junying

Zinc Die Casting Process

Design & Mold Making

Engineers design the lock parts and create a precision steel mold (die). The mold is made in two halves, allowing molten metal to be injected and the part to be ejected after solidification.

Melting the Alloy

Raw materials such as zinc or aluminum alloys are melted in a furnace at controlled temperatures. The molten metal is kept clean and at the correct viscosity for casting.

Injection / Casting

Molten metal is injected into the die cavity at high pressure (10–175 MPa). The pressure ensures that the metal fills even the smallest details of the lock part design, producing precise and strong components.

Cooling & Solidification

The molten metal cools and solidifies quickly inside the mold. Cooling time is carefully controlled to maintain dimensional accuracy and strength.

Ejection of Parts

Once solidified, the mold opens, and ejector pins push out the finished lock part. This process is fast and allows high-volume production.

Trimming & Finishing

Excess material (flash) is trimmed off. Surface treatments may follow, such as polishing, plating, powder coating, or painting to enhance corrosion resistance and aesthetics.

Inspection & Quality Control

Parts go through dimensional checks, mechanical tests, and surface inspections. Advanced equipment ensures consistency and adherence to customer requirements.

Packaging & Delivery

Qualified die-cast lock parts are packed and prepared for shipment to customers.

How to Install a Lock Part?

- Gather Tools and Parts: Ensure you have all lock components (cylinder, bolt, pins, screws, keys) and tools like screwdrivers, drill, measuring tape, and possibly a chisel.

- Prepare the Door or Surface: Measure and mark where the lock part will be installed. Drill or cut holes for the cylinder, bolt, or latch according to the lock’s specifications.

- Insert the Lock Cylinder or Core: Slide the cylinder into its hole. Make sure it sits flush with the door surface and aligns properly with the bolt mechanism.

- Install the Bolt or Latch: Position the bolt in the door edge or frame. Secure it with screws or fasteners, ensuring smooth movement when the key is turned or handle is operated.

- Attach Exterior and Interior Handles (if applicable): Fix any knobs, levers, or plates that are part of the lock assembly. Check that all parts line up and rotate freely without obstruction.

- Secure All Screws and Fasteners: Tighten all screws carefully, but avoid overtightening, which could deform the lock or misalign components.

- Test the Lock: Insert the key and turn it several times. Make sure the bolt extends and retracts smoothly, and the lock engages correctly from both sides.

- Adjust if Necessary: If the lock is stiff or misaligned, loosen screws, realign parts, and retighten. Apply lubricant to moving parts if needed.

Die casting lock parts are typically made from zinc or aluminum alloys. Zinc is popular for its strength, durability, and ability to produce intricate details, while aluminum offers lightweight properties and good corrosion resistance.

Die-cast parts are formed under high pressure, which creates a dense, strong structure with excellent dimensional accuracy. This makes them more resistant to wear, breakage, and tampering compared to stamped or plastic alternatives.

Yes. Zinc and aluminum alloys naturally resist corrosion. In addition, surface treatments like plating, powder coating, or painting further enhance corrosion resistance, ensuring a longer lifespan in different environments.

After production, die-cast lock parts undergo strict quality control, including dimensional checks, surface inspections, and mechanical strength testing. This ensures each part meets industry standards and customer requirements.

Absolutely. Die casting allows complex shapes and fine details to be reproduced consistently. Manufacturers can customize mold designs, finishes, and treatments to suit specific lock mechanisms and aesthetic requirements.