Superior Diecasting Mold Making Techniques

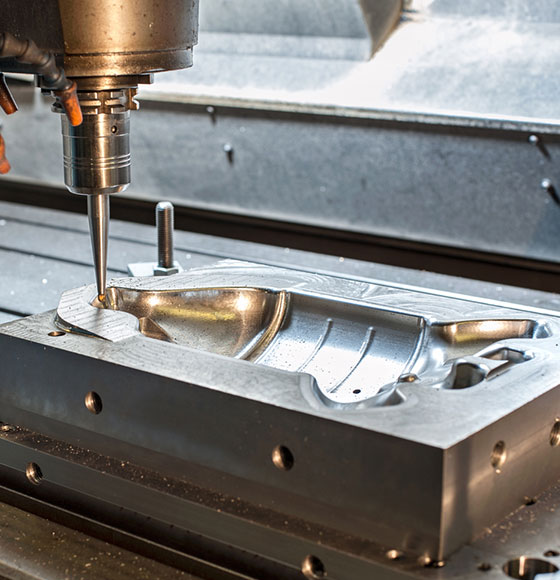

Metal components have been produced throughout years using many techniques; die casting molds and CNC machining and Die casting are the most often utilized ones. Mass-produced metal pieces are mass-cast, a high-efficiency method. Among the three fundamental components of die casting manufacturing, the die casting mold is very important. Under either low or high speed casting, molten metal is pumped into a precisely designed mold cavity in this technique. Comprising moveable surfaces, the mold presses as the metal cools and sets. This not only reduces shrinkage and porosity but also strengthens internal structure, hence improving mechanical characteristics and grain refinement.

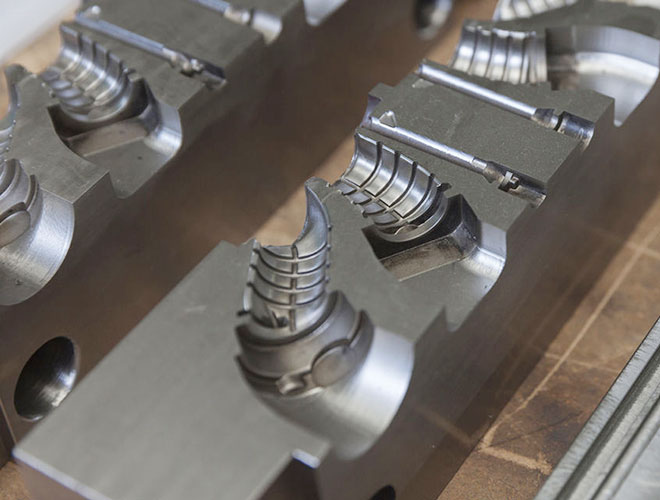

Structure of a Die Casting Mold

A standard die casting mold consists of two main components:

- Stationary (fixed) mold half – Mounted on the die casting machine’s fixed platen.

- Movable (ejector) mold half – Fixed on the moving platen and includes the casting ejector system.

When casting begins, the two halves are clamped together by die locking force. The interface between both halves is known as the parting line. Opening and closing operation.