China Aluminum Die Casting Industry Report 2019-2022 - Development Trend, Market Demand & More

The following is a data analysis report of China’s aluminum die-casting industry for 2020-2022, which introduces in detail the market competition situation of aluminum die casting manufacturing industry, the independent innovation and development trend of aluminum die casting technology.

2019-2022 China Aluminum Die Casting Industry Report

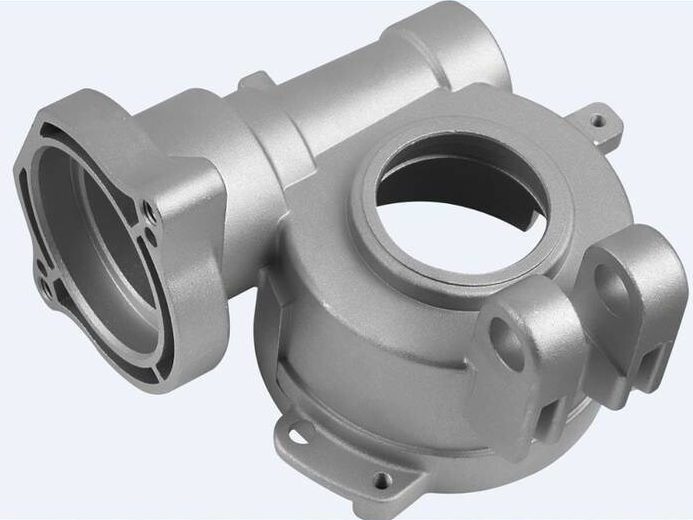

Aluminum die casting is a high-precision spare parts production technology with the most common use, faster development trend, the most excellent technology and the largest efficiency. It is integrated into the development trend of complex, precision, light weight, environmental protection and energy conservation and low-carbon environmental protection in the contemporary processing industry. As this kind of metal material heat treatment technology with less drilling and close to non drilling condensation forming, aluminum die-casting products have many advantages, such as light material, strong wear resistance, high impact toughness, good heat conduction and conductivity, high temperature bearing, beautiful surface, high environmental protection and energy saving efficiency, and so on. Therefore, it is widely used in automobiles, household appliances, airlines and machinery Equipment and other high-precision electronic components.

Aluminum Die Casting For Automobile Industry

In recent years, with the development trend of the world economy, the requirements of precision die casting in many industries, such as automobile, communication basic machinery and equipment, electrical products, medical equipment and so on, continue to grow. In China, the proportion of the car casting production in the total casting production in China has already exceeded 70%. In recent years, the automobile new energy requirements have greatly promoted the high-speed development trend of the automobile aluminum alloy profile precision die-casting industry chain, and the aluminum alloy die casting parts play a very important role in the automobile industry.

Aluminum Die Casting Market 2019-2022

At present, the production, manufacture and consumption of aluminum die casting in the world are mainly concentrated in Japan, China, Spain, France, Spain and other countries. With the continuous improvement of economic development, the world demands more commodities such as automobiles, electronic device communication, etc., and the aluminum die casting manufacturing industry has been developing rapidly.

At present, most of the small and medium-sized die casting plants produce and manufacture hardware accessories, lighting lamps, small toys and other general aluminum die casting products. The company has small scale, low level of machine equipment, fierce price competition and low economic benefits. The few die casting enterprises with large scale have excellent machine equipment and technology, which can produce and manufacture the products in line with the requirements of the industrial chain of small cars, high-grade household appliances, pneumatic tools, communication and other industries. This kind of producer can create a stable long-term cooperative relationship with the customers in the middle and lower reaches, and it is in a beneficial influence in the market demand, and the company has good economic benefits.

Innovation And Development Trend Of Aluminum Die Casting 2020, 2021, 2022

1.Integrated

Traditional die-casting enterprises only specialize in the production of casting parts, and the goods are handed over to the assembly line of integrated manufacturers in the middle and lower reaches. The production mode and process flow are very simple. Now the modern processing process is becoming more and more complicated. The regulations on the high efficiency of supply chain management in commodity welding companies are obviously improved, and the regulations on the integration of spare parts in the sales market are higher and higher. Some die casting enterprises have gradually changed from a single casting manufacturer to an integrated aluminum die casting part manufacturer.

2.Application of new technology

With the development trend of industrialization, the requirements of casting quality in various manufacturing industries are becoming higher and higher. The market demand for large and medium-sized, thick wall and thick wall pipe castings with large manufacturing difficulty coefficient is also expanding day by day, which promotes the continuous creation of new production technology.

3.New materials

Raw materials are one of the most important elements in industrialization. The application of new materials can usually lead to the upgrading of commodities, technological innovation and even technical reform. In the aluminum die casting manufacturing industry, the use of new materials is varied, including two aspects: first, the emergence of new alloy products, such as magnesium alloy die casting. Second, improving the secret formula of the original alloy products, so as to obtain the characteristics that the original aluminum alloy does not have, so as to develop new products for design and application in new fields.

4.Crisis management

In the automobile industry, with the development trend of economic development, the market demand is increasing day by day, and the rate of commodity upgrading is also gradually accelerating. In order to meet the needs of the market, the middle and lower stream companies must continue to be old and innovative, which also promotes the upstream and downstream die-casting manufacturers to have more product varieties and change faster, which clearly puts forward higher requirements for the ability of die-casting manufacturers to deal with crisis. In order to improve the ability to deal with the crisis, the die casting supplier must improve its ability of product research and development, accumulate technology with diligence, and carry out standardized and professional management methods in product R & D.