-

Apr.17

2024

3/8 vs 1/2 vs 1/4 Cable Clamps, Which Are Better?A cable clamp is a device used to secure and organize electrical cables, wires, or hoses. It is typically made of metal,...View More >> -

Apr.17

2024

How to Reduce 3D Printing Residual Stress – Diecasting-Mould.comResidual stress is an inevitable product of rapid heating and rapid cooling, which is inherent to the laser powder bed f...View More >> -

Apr.12

2024

What is Liquid Metal: Compositions, Densities, Advantages & ApplicationsDo you know about liquid metals? According to reports, liquid metal has the characteristics of fatigue resistance, high ...View More >> -

Apr.12

2024

Ferrous Metal vs Non-Ferrous Metal & Differences Between ThemIron, chromium, and manganese are listed as ferrous; Include 64 metals other than iron, chromium, and manganese as non-f...View More >> -

Apr.11

2024

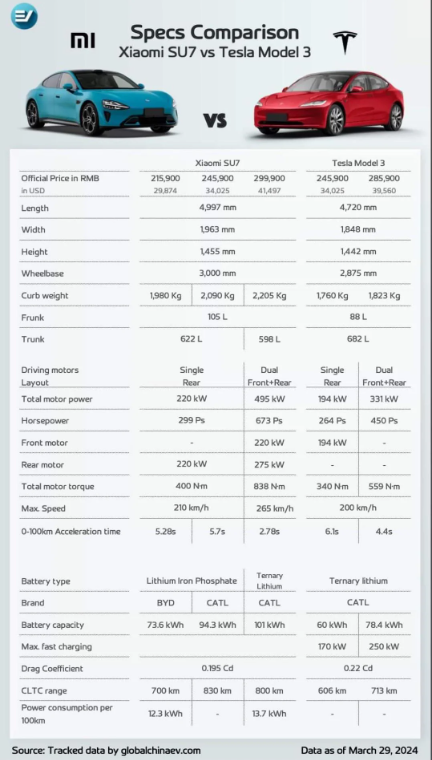

Xiaomi SU7 vs. Tesla Model 3: Which One is More Worth Buying?The sales volume exceeded 50,000 in less than half an hour. Although Xiaomi SU7 achieved amazing sales results at the pr...View More >> -

Mar.25

2024

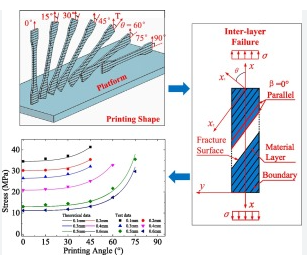

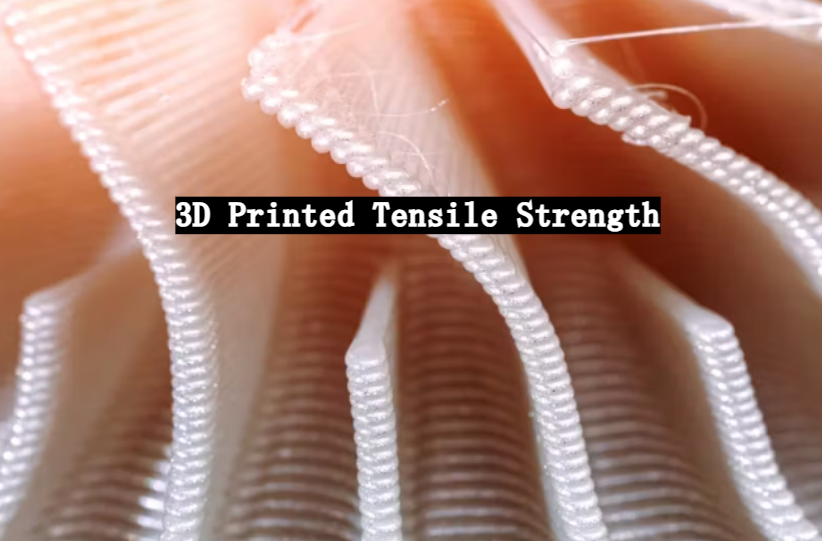

What Impacts 3D Printed Tensile Strength & How To Increase?While the type of plastic material used plays a crucial role in determining the ultimate strength of the final product, ...View More >> -

Mar.22

2024

TIG Welding: Definition, Application, How to Work, Types, and moreTIG welding, also known as gas tungsten arc welding (GTAW), is an arc welding process that uses a non-consumable tungste...View More >> -

Mar.22

2024

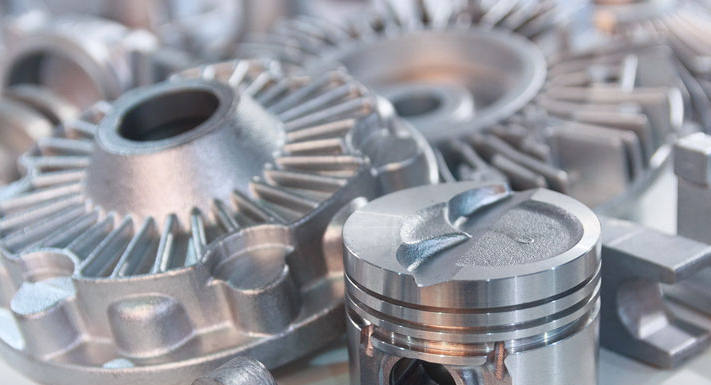

What is Pressure Die Casting? – Definition, Types, Uses, and morePressure die casting is a metal casting process that is commonly used to produce complex products with close dimensional...View More >> -

Mar.20

2024

Aluminum 3003 vs Aluminum 6063, What’s the Difference | Diecasting-mouldAluminum alloys are some of the most widely used engineering materials in the world due to their high strength-to-weight...View More >> -

Mar.20

2024

What is Inconel? – Definition, Uses, Types, and moreInconel is a nickel-chromium-based superalloy that is highly resistant to corrosion and heat. In this article, we will e...View More >> -

Mar.18

2024

Mold Coating Guide: Advantages, Types & How To ChooseMold coating refers to the application of specialized coatings on the surfaces of molds used in tooling production. Thes...View More >> -

Mar.15

2024

What’s The Best Aluminum For Bending?When processing sheet metal parts or designing sheet metal components, encountering problems such as aluminum plate cann...View More >>