- Our Services

- Aluminum Die Casting

- Zinc Die Casting

- CNC Machining Services

- Products

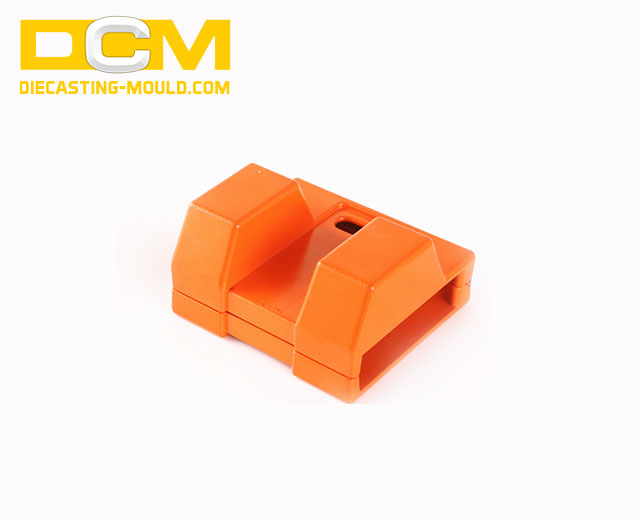

- Die Casting Cable Clamps

- Die Casting Lamp Shade

- Die Casting Lock Parts

- OEM Die Casting Parts

- Contact Us

- Phone: +86 769 8289 0830

- Email: [email protected]

-

Address: #3, Changfu Road, Ludong, Humen, Dongguan, Guangdong, 523935, P. R. China.

Best OEM/ODM Die Cast Parts Factory – Custom Die Casting Products

Junying (Diecasting-mould.com) is specialized in pressure die casting process and aluminum/zinc metal castings production for more than 15 years, we are capable to provide complex OEM die casting parts for your specific applications and purposes. A thorough understanding of die casting techniques enables us to create cost-effective die casting products with the best performance and exact dimensions to meet your request, premium quality and competitive prices will make your stand out in local market. We’ll apply advanced machinery and systems to alleviate risk during the process. Lightweight yet strong aluminum or different zinc materials are available for selection, such as A360, A380, ADC2, etc. Several parts can be cast into a single unit, which simplifies the supply chain. DiecastingMould provides one-stop service for the OEM clients, our custom die casting parts market including door locks, automotive, heavy equipment, lightning, electrical cable clamps, vehicle, and more industries and fields. Whether you require a new product design or OEM die castings of finished design, welcome to get in touch with us, a free quote will be sent back within 24 hours. Mold design and mold making for OEM parts, as well as surface finishing services, are offered for your requirements.

High Quality Aluminium/Zinc/Magnesium Die Casting Components

JUNYING is a professional manufacturer specializing in the design and production of magnesium, aluminum, and zinc alloy die casting parts, gravity casting, and aluminum profile CNC machining components. We provide comprehensive one-stop services from mold design and development to die casting, post-processing, and surface treatment. Our die casting products are widely used in intelligent automation equipment, 3C products, medical devices, automotive parts, machinery components, power tools, household appliances, LED lighting, and various metal structural parts across industries.

Aluminium Die Casting Components, Parts, Products

Aluminum die casting involves pouring molten aluminum or aluminum alloy into sand or metal molds to create parts of various shapes and sizes. Due to its excellent material properties, lightweight, and ease of forming, aluminum die cast parts are fundamental components in automotive, communications, elevator, electronics, and machinery industries. JUNYING offers high-quality precision die cast car parts such as cylinder blocks, cylinder heads, intake manifolds, and brake valve bodies.

Zinc Die Casting Components, Parts, Products

Zinc die casting is a precision casting process where molten zinc alloy is injected under high pressure into metal molds. It is widely used for producing complex-shaped, thin-walled, or finely textured metal parts. Zinc die cast components feature high density, strength, wear resistance, and support various surface treatments like plating and spraying. With a low melting point (~385°C) and excellent fluidity, zinc alloy die casting parts can form ultra-thin walls (minimum 0.3mm thickness), making them ideal for hardware, electronics, automotive parts, and crafts.

Magnesium Die Casting Components, Parts, Products

Magnesium die casting uses magnesium alloys as the casting material, offering high strength-to-weight ratio and excellent thermal properties compared to traditional aluminum alloy casting. Magnesium’s melting point allows the casting of complex, finely detailed shapes. Magnesium die cast parts are widely applied in automotive engine blocks, transmission housings, and structural components. Its superior damping properties make it ideal for automotive parts requiring vibration and noise control, especially in new energy vehicles and electronic device manufacturing.

Advantages of Our ODM/OEM Custom Die Casting Components

- High efficiency for high volume production runs of complex components

- Dimensional consistency, superb surface finishes

- Based on your desired specification and configuration adds improvement

- Strict quality management and test for our OEM die cast components

- Standard or tight tolerance are both available

- Skilled engineers and technicians deliver cost-effective solutions

- Constant effort to improve the development and performance of casting parts

- Extensive experiences in the manufacturing of precision die castings especially lock parts

- Fast turnaround, on-time delivery and affordable prices